News

Stay updated with the latest news, innovations, and developments from Soudronic. Explore upcoming events, industry trends, and our achievements in the world of metal packaging solutions. Whether it’s trade shows, product launches, or company milestones, this is your hub for everything happening at Soudronic Group. Join us as we continue to lead the way in innovation and excellence and subscribe to our newsletter.

Filter by

-

Season’s Greetings from our CEO

Dear customers and partners, as the year comes to an end, I would like to take a moment to reflect on what has been an intense and challenging year for all of us.

-

Pacprocess Egypt in Cairo, 2025

We look back on our participation at Pacprocess Middle East Africa 2025 in Cairo, which took place from 9–12 December 2025. We were pleased to be present alongside our agent Promoting International Co.

-

Latamcan 2026, Mexico City

LATAMCAN returns to Mexico City, bringing together the can making industry from across the Americas. Meet our team at table #46 and take the opportunity to discuss current market developments.

-

On-call teams and local office availability 2025 / 2026

Need support? Here’s how to contact our on-call team during the holiday season. It also provides an overview of all subsidiary closures throughout the holidays.

-

Phase-out «ARTER» gearboxes – LAST CALL

As of June 2026, our supplier will end the production of «ARTER» gearboxes. At the same time, revisions and servicing for these gearboxes will also no longer be offered.

-

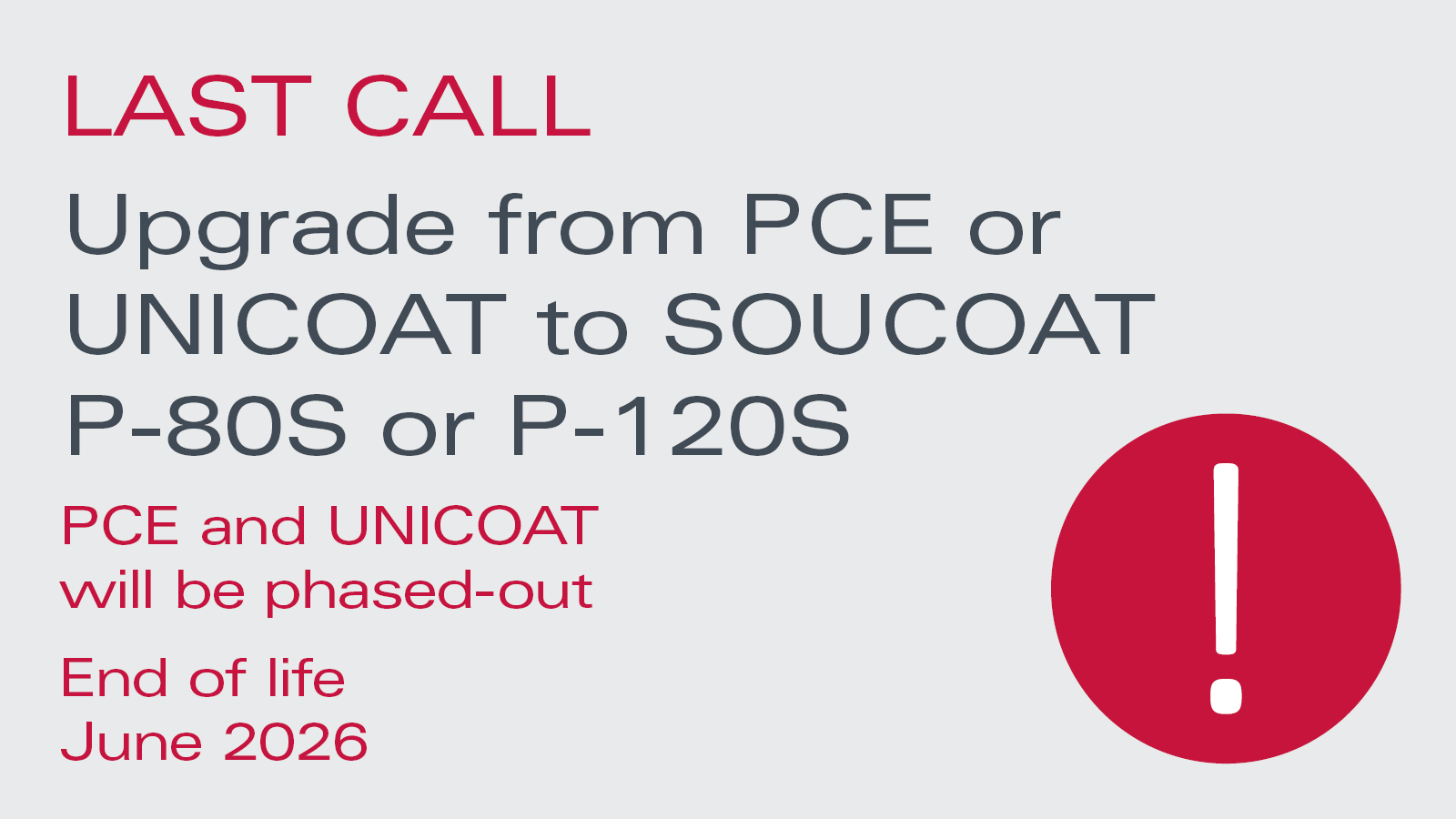

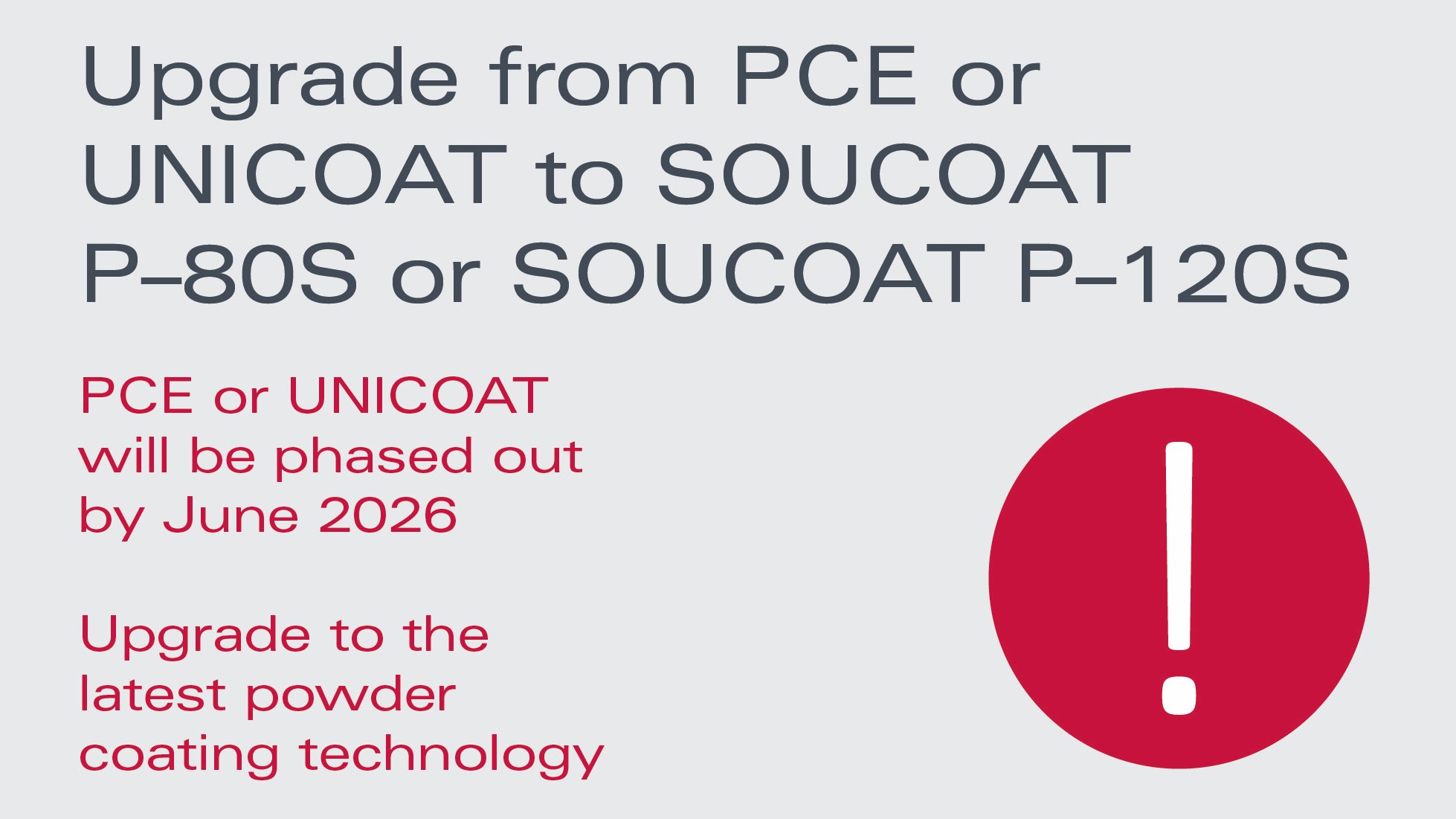

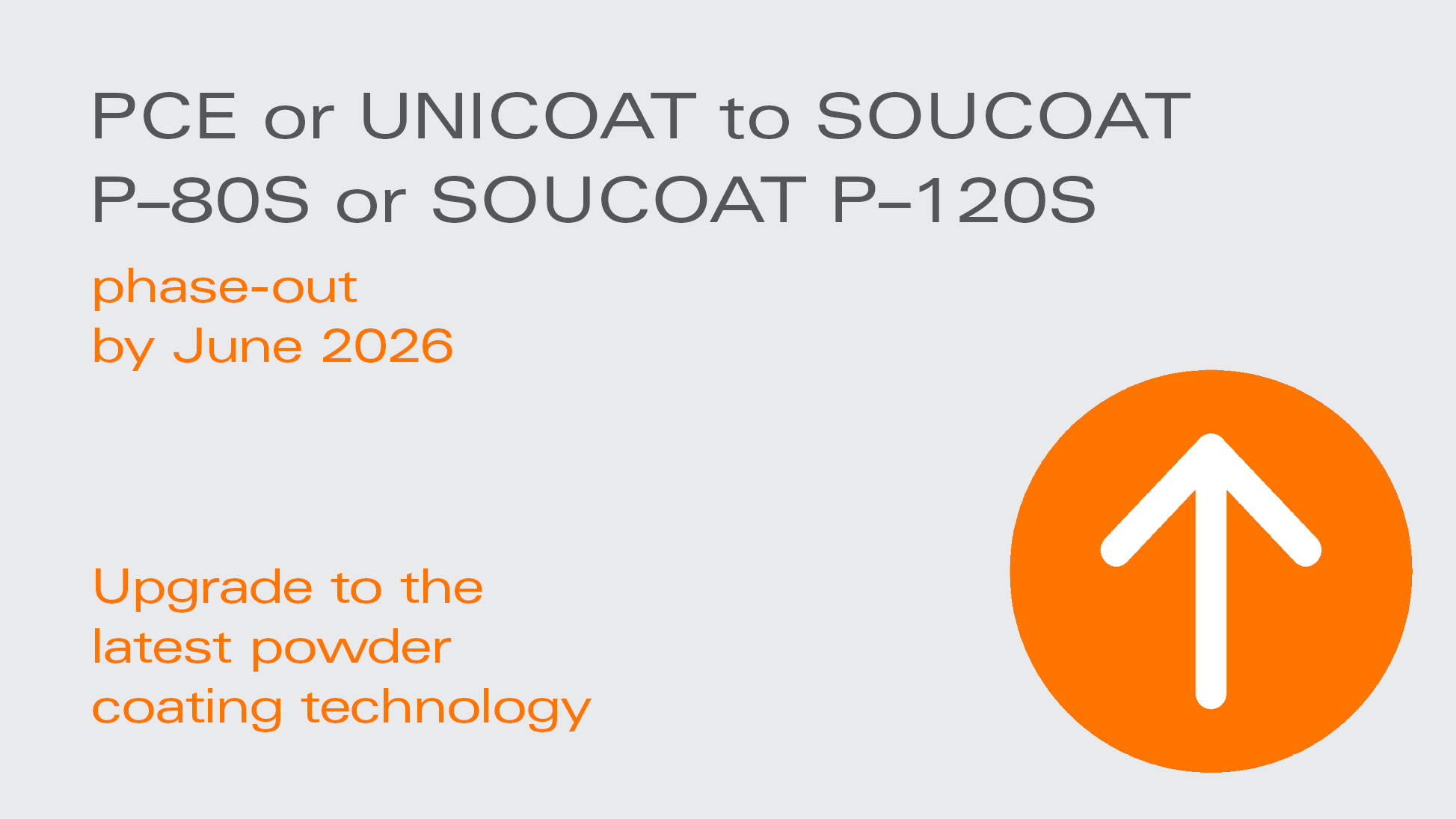

Phase-out – PCE and UNICOAT – LAST CALL

Soudronic will discontinue the PCE and UNICOAT systems by June 2026. With the latest SOUCOAT (P-80S and P-120S) generation, a technologically further advanced product is now available. Please get in touch with us to plan the next steps.

-

Soudronic at Metpack 2026

Mark your calendar for Metpack 2026, the world’s leading trade fair for the metal packaging industry, taking place in Essen, Germany.

-

Interpack 2026 – Düsseldorf

We’re excited to participate in Interpack 2026, in Düsseldorf, Germany, the world’s leading trade fair for the packaging sector and related processing industries.

-

Phase-out «ARTER» gearboxes – Upgrade now!

Our supplier has notified us that production of the «ARTER» gearboxes will be discontinued as of June 2026. In addition, revisions and servicing of these gearboxes will no longer be available starting June 2026.

-

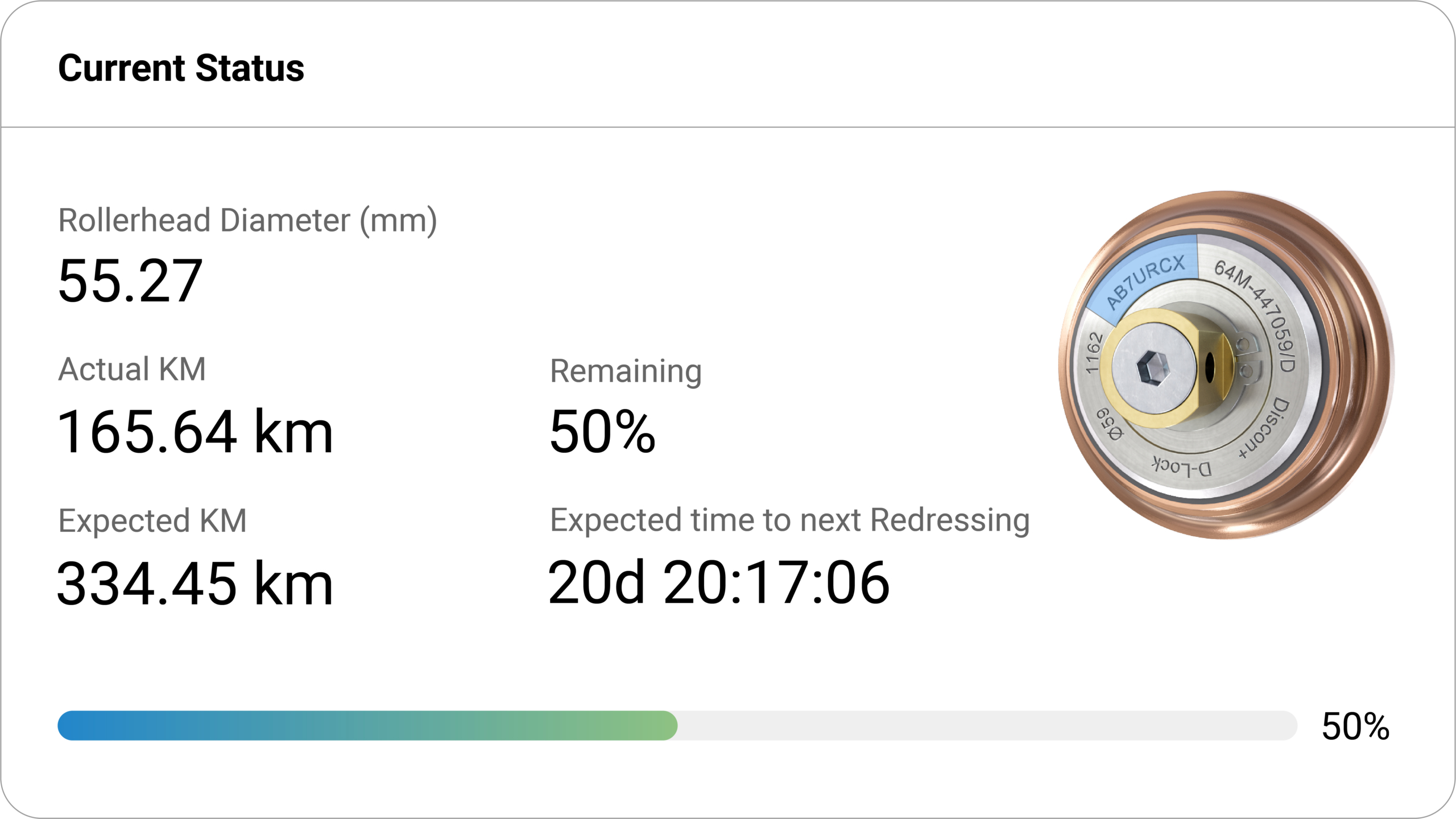

DISCON+ roller head performance dashboard

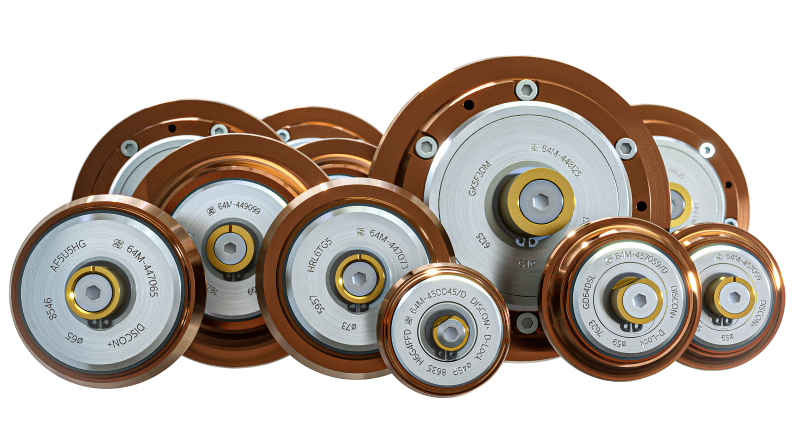

DISCON+, the latest generation of our renowned roller head for canbody welding machines, was launched in July 2023. Built from advanced materials and fitted with improved seals, it delivers a new level of food safety. Equipped with an ID it connects to a digital performance dashboard.

-

Gulfood Manufacturing Dubai 2025

We were pleased to participate in Gulfood Manufacturing 2025, held from November 4–6, 2025, in Dubai.

-

Frei AG – Celebrating 50 years of excellence

At Soudronic, we don’t just celebrate milestones; we honor the legacy of those who’ve shaped the industry with us. In 2025, we join in celebrating a momentous occasion—the 50th anniversary of Frei AG.

-

New COMPACT video with all features

Looking for a flexible canbody welder that combines cutting-edge technology, top-tier safety, and unbeatable value? Backed by Soudronic’s trusted service, the new COMPACT delivers exactly that.

-

New general manager at Soudronic Ltd., USA

After a long and successful career at Soudronic, Kurt Sami will be retiring. Under his leadership, our presence in the U.S. has grown steadily and significantly. As of 1 August 2025, Stefano Capoccia will assume the role of General Manager.

-

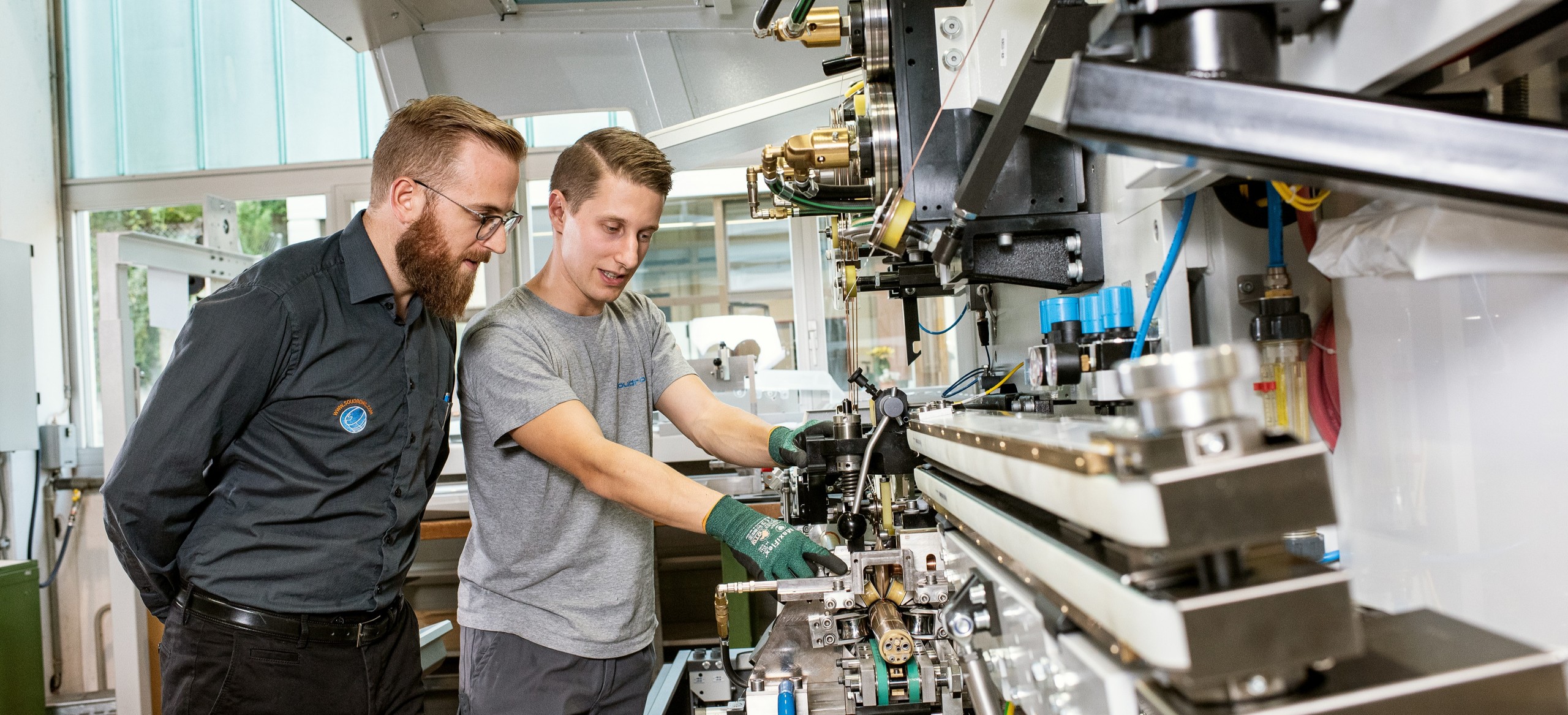

Congratulations to our 2025 graduates

A warm congratulations to the apprentices who successfully completed their training this summer. Over the past three or four years, they have shown not only technical ability but also perseverance, curiosity and a strong sense of responsibility.

-

Phase-out – Upgrade from PCE and UNICOAT now

Soudronic will phase-out the PCE and UNICOAT by June 2026. Upgrade to the latest powder coating technology. Soudronic developed the PCE powder system in 1988, which was renamed UNICOAT in 2002. The system was sold until 2005. Due to the …

-

Smarter measuring of energy consumption

Monitoring and providing proof of energy consumption in production machinery is increasingly important—not only for internal efficiency but also to comply with regulatory requirements in certain countries and industries.

-

RESPack 2025, Mumbai

The International Press Conference on Responsible Packaging, RESPack 2025, was held in Mumbai on June 2–3, 2025 The conference brought together experts and stakeholders to explore optimal design, innovative materials, and sustainable technologies in packaging. The program included a plenary …

-

Latamcan 2025, São Paulo

From May 21 to 23, 2025, we had the pleasure of attending Latamcan in São Paulo, Brazil. The event gathered can making professionals from across Latin America and beyond.

-

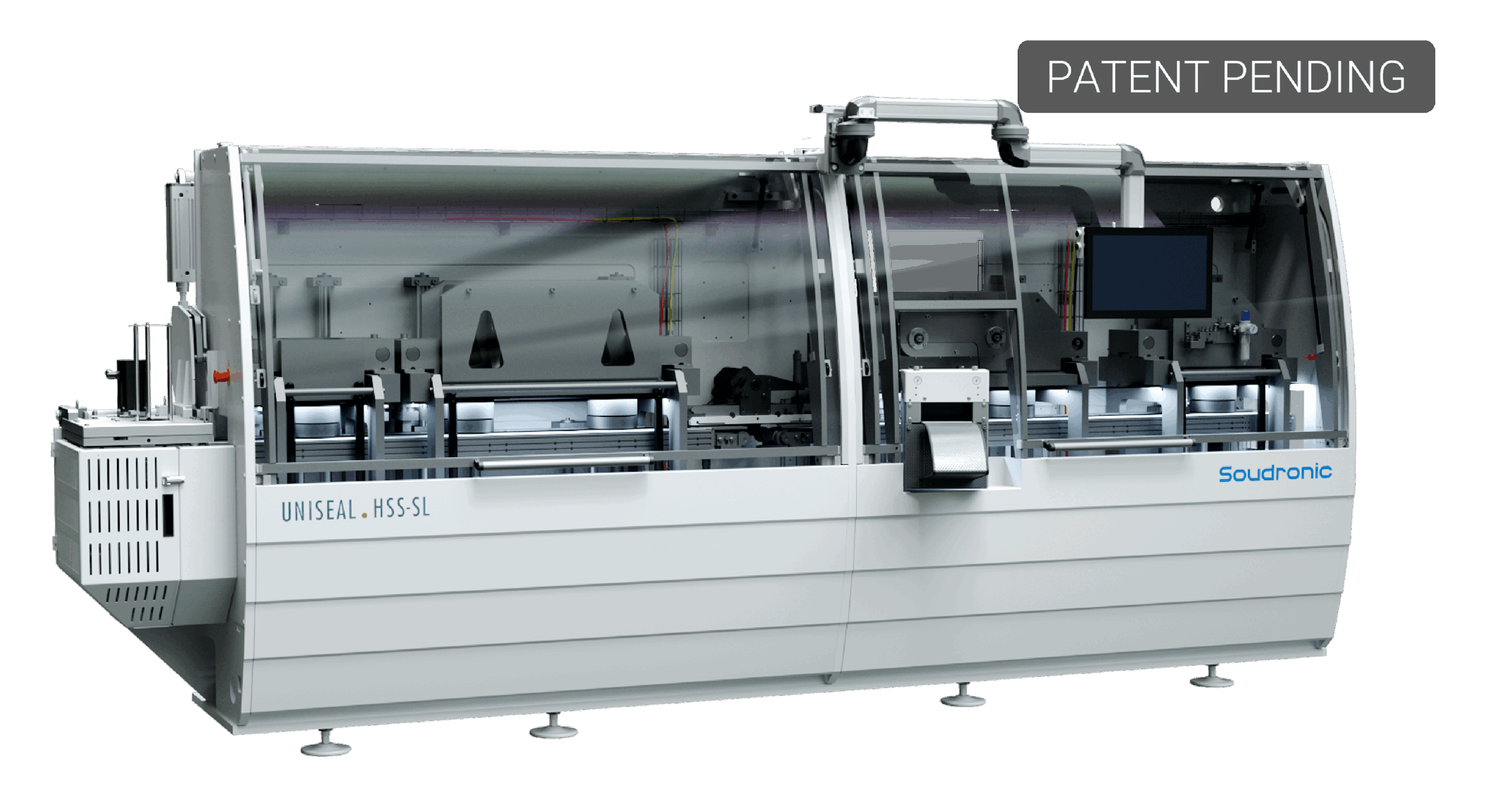

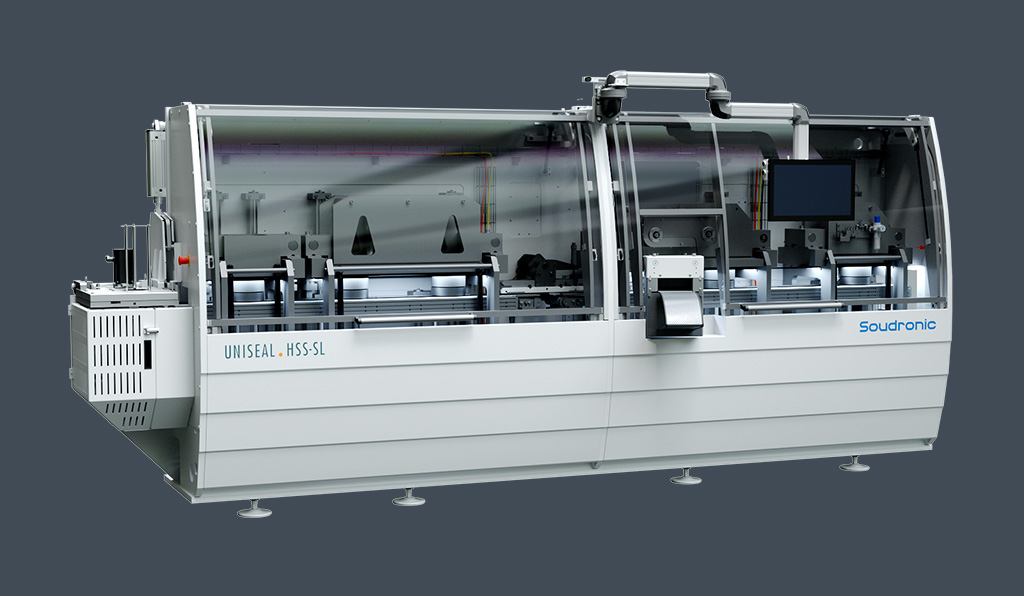

UNISEAL HSS-SL: Proven concept in action

What started as a prototype in 2019 has since evolved into a reliable production solution: the UNISEAL HSS-SL, our single-lane heat-sealing system, has now been operating successfully for over three years at SILGAN Metal Packaging.

-

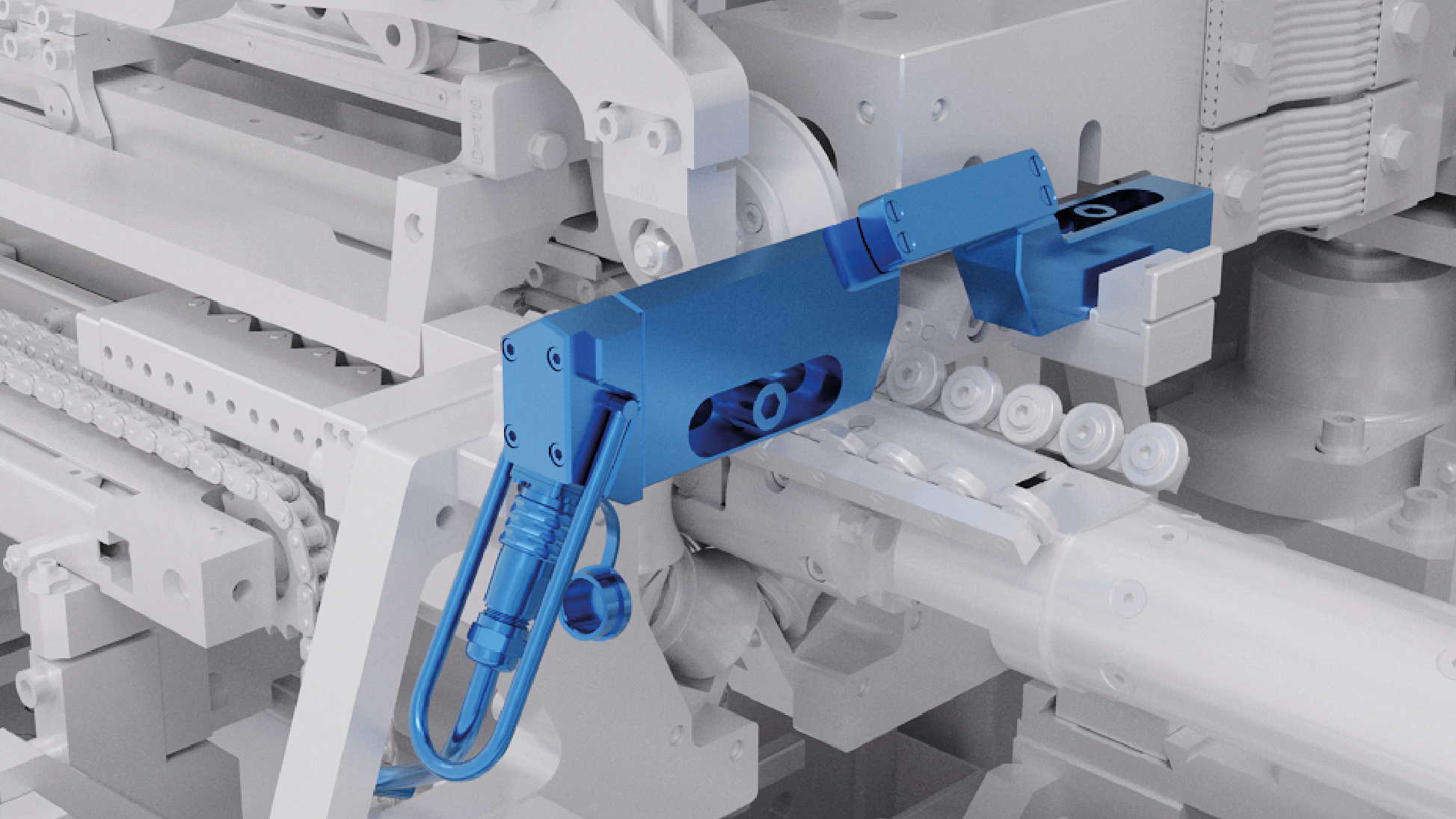

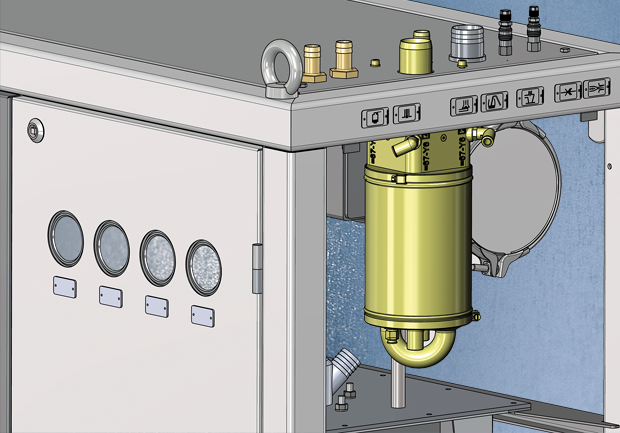

One circuit, twice the impact: the new FLUID+ cooling system

Until recently, the cooling systems for welding machines and DISCON+ roller heads operated separately—adding complexity to maintenance, servicing, cleaning and food safety requirements. With the launch of the new FLUID+ cooling system, that’s changed.

-

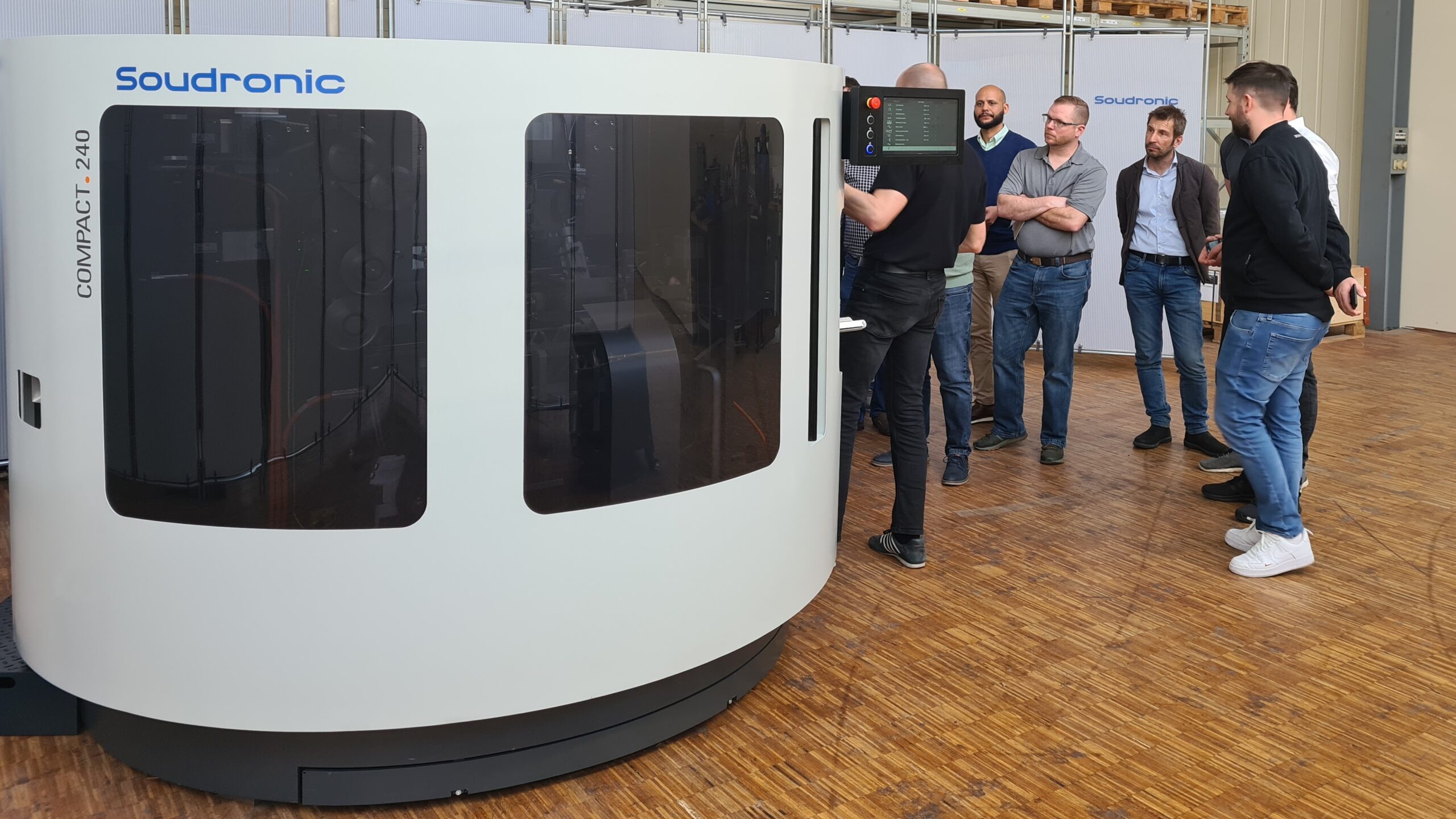

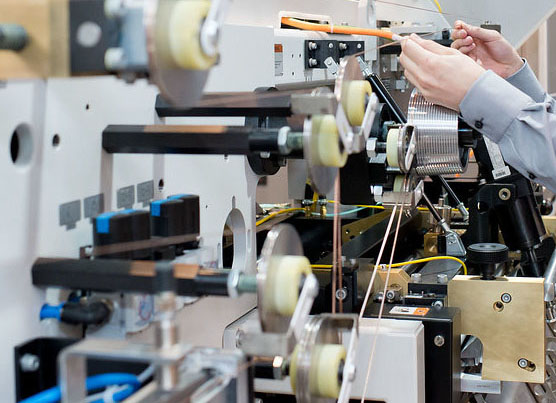

IPA members impressed by live demonstration at Frei AG

On April 2, 2025, around twenty members of the International Packaging Association (IPA) gathered at Frei AG in Wittenbach for a highly anticipated plant visit, highlighted by the exclusive live presentation of Soudronic’s latest innovation—the COMPACT 240 welding machine.

-

Becoming a Soudronic service engineer

Kannan’s journey: From India to Switzerland and beyond. When Kannan first saw the job ad for a Service Engineer position at Soudronic, he envisioned working for Soudronic’s headquarters in Switzerland. Little did he know that his journey would take him much further.

-

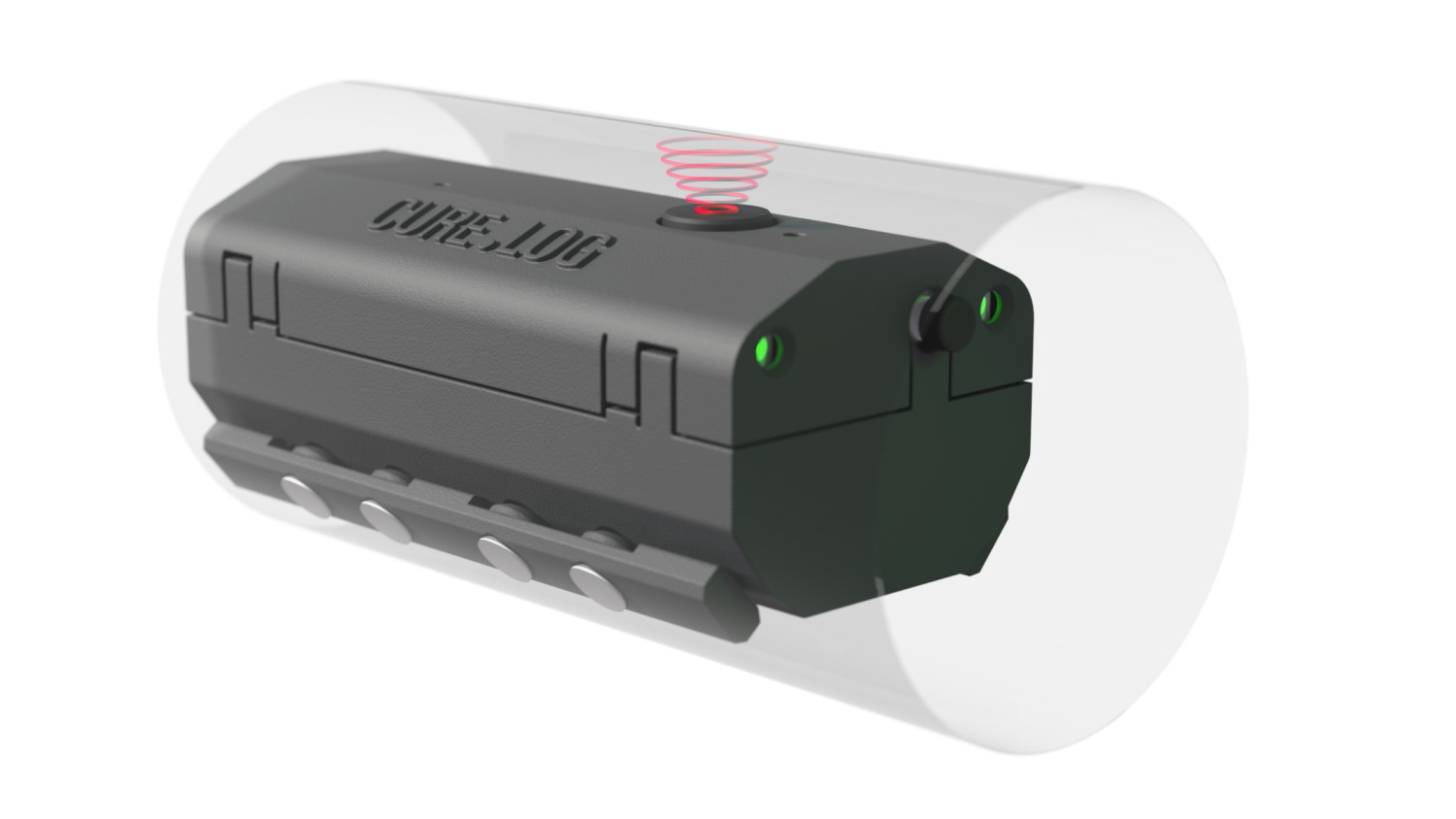

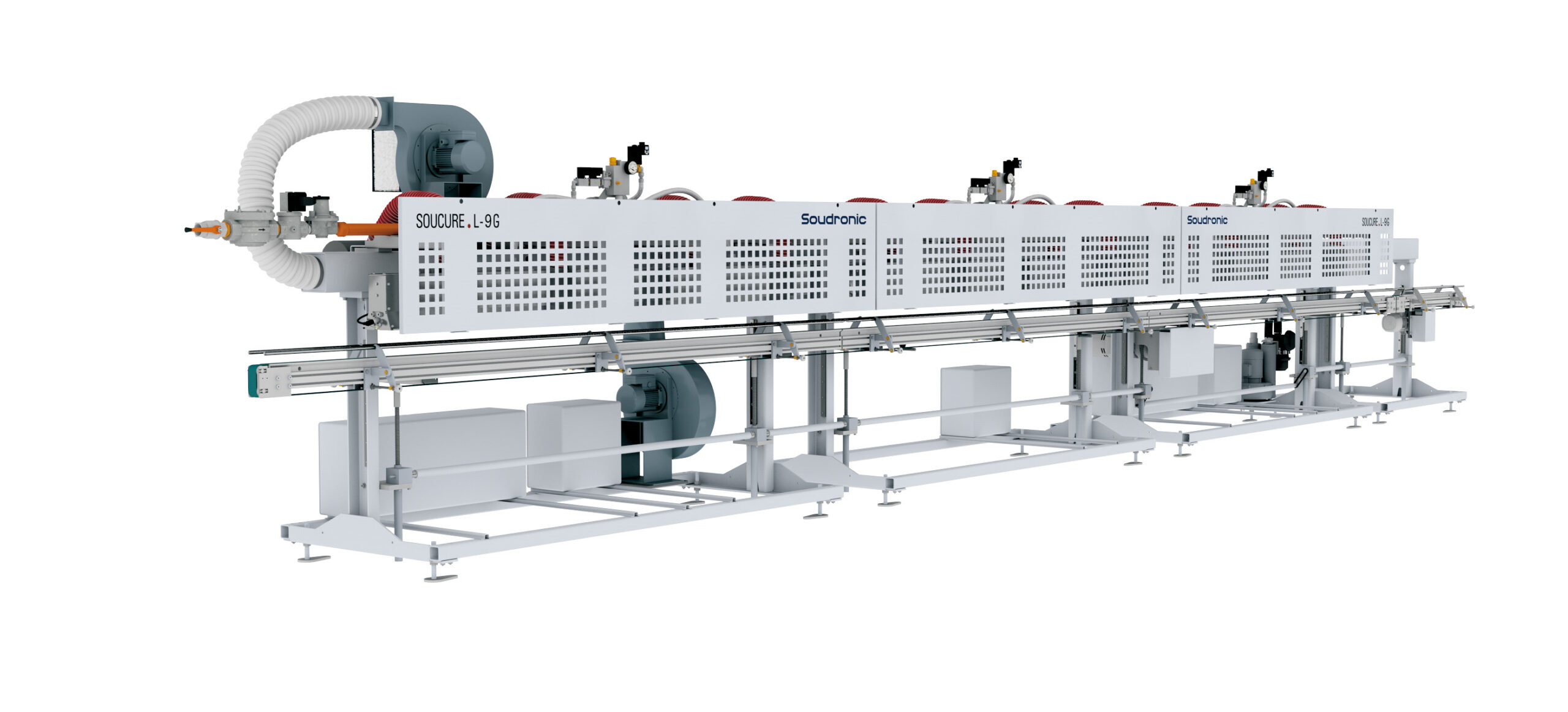

Optimizing curing processes

Oriental Tin Can relies on CURE.LOG. In the competitive world of food can manufacturing, precision, and efficiency are paramount. Oriental Tin Can, one of the Philippines’ leading food can producers, understands this better than most.

-

Discontinuation DPC, HPC powder seam coating technology

The electronic components used in DPC and HPC systems have been discontinued, making it essential to plan for their replacement. To facilitate a seamless transition, a special trade-in offer is available for upgrading to the advanced PowerCOAT iP system. Affected …

-

Season’s Greetings 2024

Enjoy watching our Season’s Greetings movie. Celebrate this special time of year with us! We wish you a peaceful Festive Seasonand a Happy New Year. Wir wünschen Ihnen frohe Festtageund einen guten Rutsch ins neue Jahr. Nous vous souhaitons de …

-

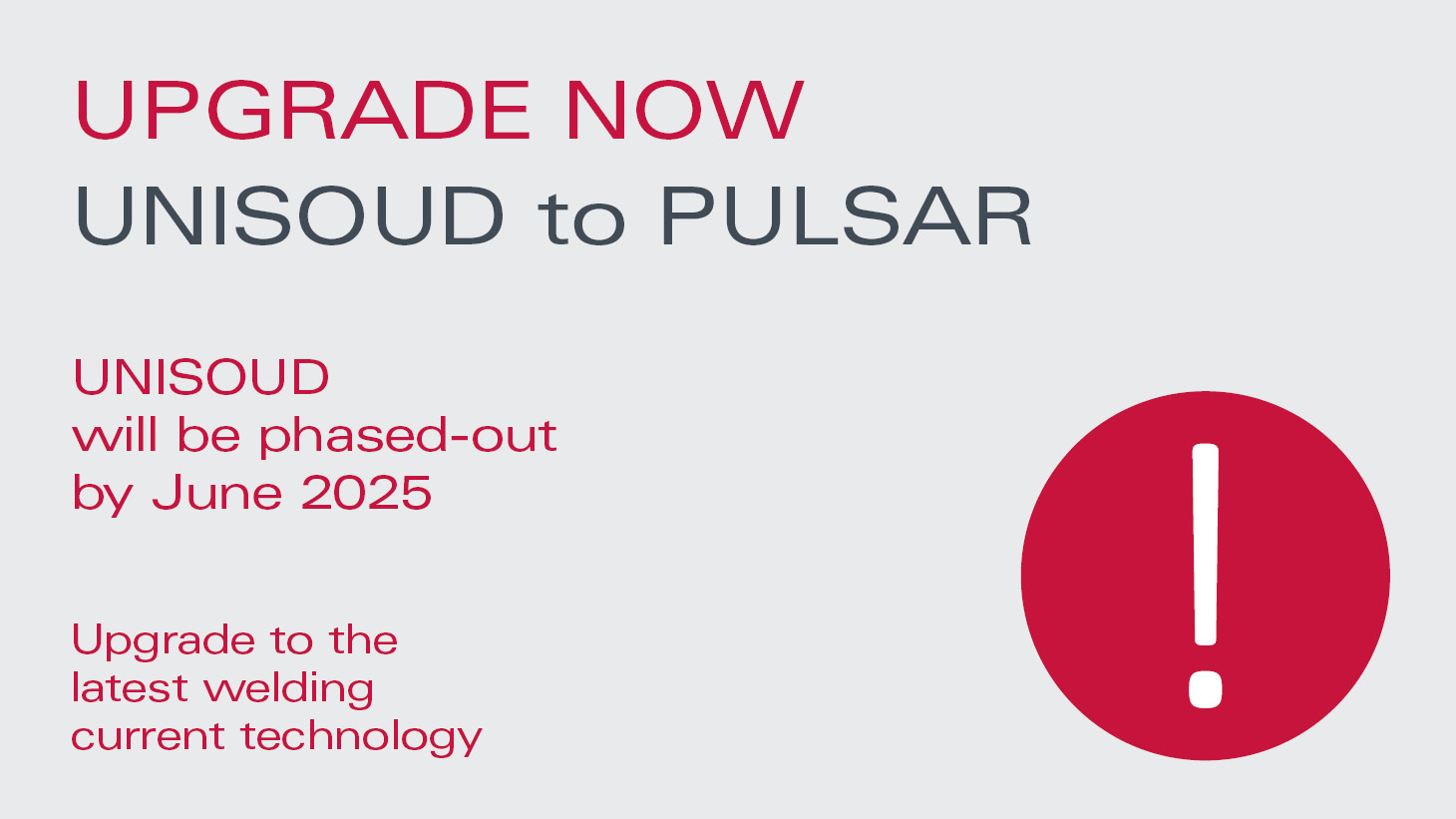

Phase-out of UNISOUD, upgrade to PULSAR

Soudronic will be phasing-out the UNISOUD converter by June 2025, due to increasing difficulties in sourcing the electronic components. Please refer to our upgrade section or this flyer for key details about this change and recommended actions.

-

Offices closed for holidays and contact details of on-call team

Please be informed that our headquarters in Switzerland will be closed from December 21, 2024 until January 5, 2025 in observance of the Christmas holidays. Normal operations will resume on January 6, 2025. On-call team Our on-call team is available …

-

Indian Aerosols Expo 2025, Mumbai

We were privileged to participate in the Indian Aerosols Expo held in Mumbai from 28 February to 1 March 2025. This event provided an excellent platform to interact with industry experts, customers and partners, facilitating the exchange of valuable insights. …

-

Phase-out ORC, DRC roller coating technology

ORC, DRC equipped with EATON MOELLER PLCs Production of unit has been stopped because key components are no longer available. As suppliers phase-out many electronic components used in older Frei AG systems, the need to adapt electrical systems to accommodate …

-

Cannex Fillex de las Américas, Denver

We were pleased to take part in the Cannex Fillex de las Américas exhibition in Denver, Colorado, USA, which took place from April 29 to May 1, 2025. The event was a great opportunity to showcase our innovations and connect …

-

Case study: mySoudronic with Silgan Containers

Enhancing production efficiency with mySoudronic When mySoudronic was introduced in fall 2023, a customer portal designed to support our customers and their operating personnel anytime, anywhere, and on any device, Silgan Containers was one of our first customers to embrace …

-

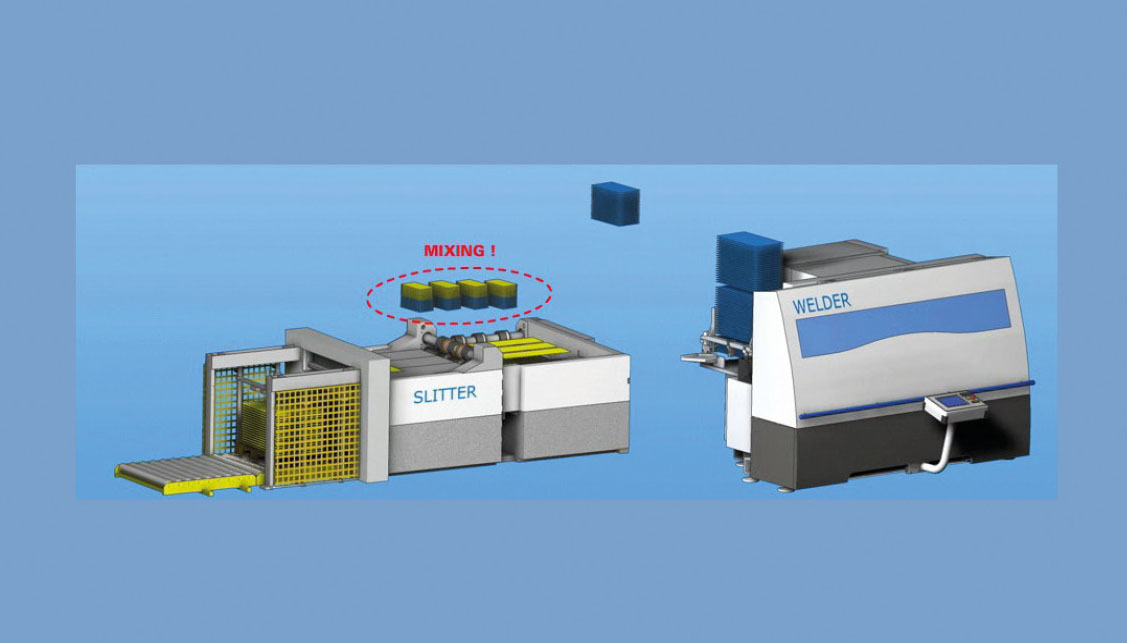

The new COMPACT 240

Swiss quality, surprisingly affordableWe are thrilled to introduce the COMPACT 240, a versatile welder from Soudronic. With a compact design, it fits seamlessly into any production line and can weld up to 240 cans per minute. Follow the link below for a full …

-

PowerCURE Preheater

Short of space within your production line, but in need for a longer curing oven? Simply install the new PowerCURE Preheater to ramp-up the temperature. The short induction curing oven only measures 1.5 meter! Equipped with either one or two …

-

Gulfood Manufacturing Dubai 2024

We had an interesting time at the Gulfood Manufacturing Food Tech Show, which took place from November 5 – 7, 2024 in Dubai. Throughout the event, we had insightful conversations with industry professionals, customers, partners, and friends, supported by our …

-

Completion of apprenticeship 2024

We are thrilled to announce that eleven apprentices have successfully passed their qualification process! Through their diligence and commitment, they have achieved excellent grades, and we are very proud of them. At our headquarters in Bergdietikon, Switzerland, we are currently …

-

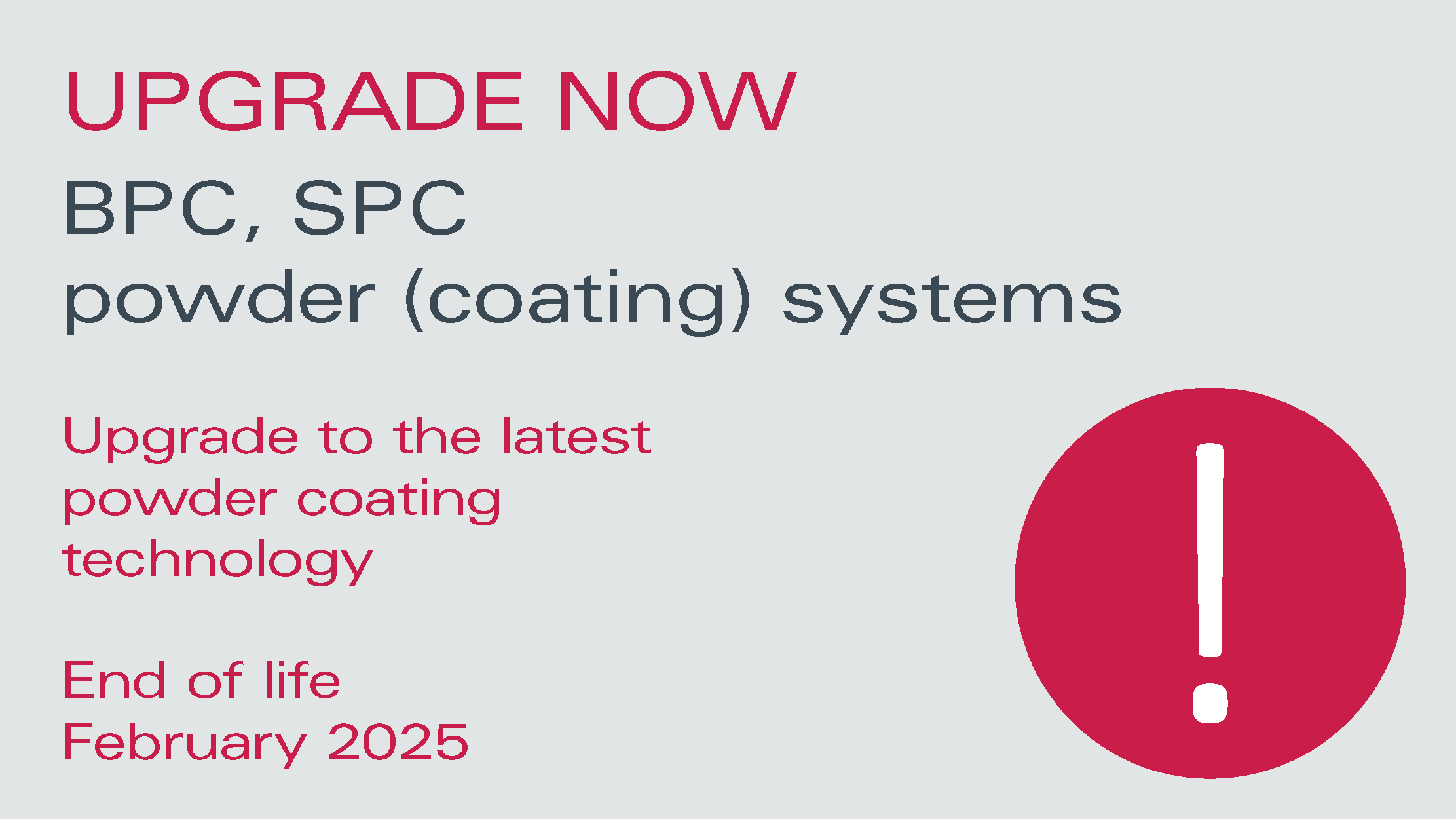

Phase-out BPC, SPC: LAST CALL

Production of unit has been stopped because key components are no longer available. With many electronic components in older Frei AG systems being phased-out by suppliers, there is an increasing need to adapt electrical systems to accommodate new, equivalent replacements. …

-

Phase-out PCA, PCB and ECM, FCM: LAST CALL

Production of unit has been stopped because key components are no longer available. Since numerous electronic components in older Frei AG systems are being discontinued by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is ever …

-

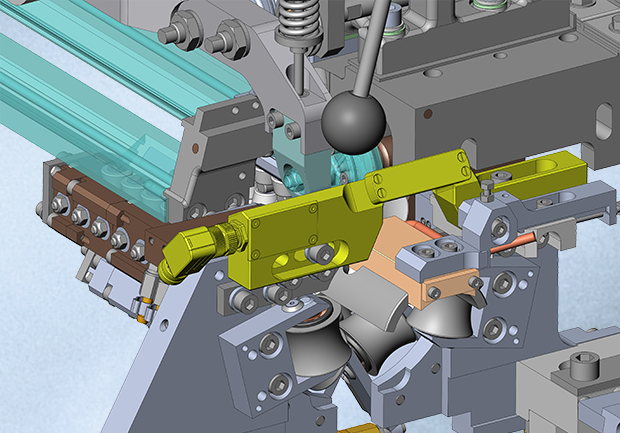

Calibrating Force Monitor channel (CFM)

Detecting deviating overlaps and cold welds. Until now, cold welds caused by overlap errors were almost undetectable. The new Calibrating Force Monitor channel (CFM) detects deviations by measuring the force in the calibration tool, and faulty canbodies get ejected immediately! …

-

Phase-out from PCE and UNICOAT, upgrade to SOUCOAT P-80S or SOUCOAT P-120S

Soudronic will phase-out the PCE and UNICOAT by June 2026. Upgrade to the latest powder coating technology. Soudronic developed the PCE powder system in 1988, which was renamed UNICOAT in 2002. The system was sold until 2005. Due to the …

-

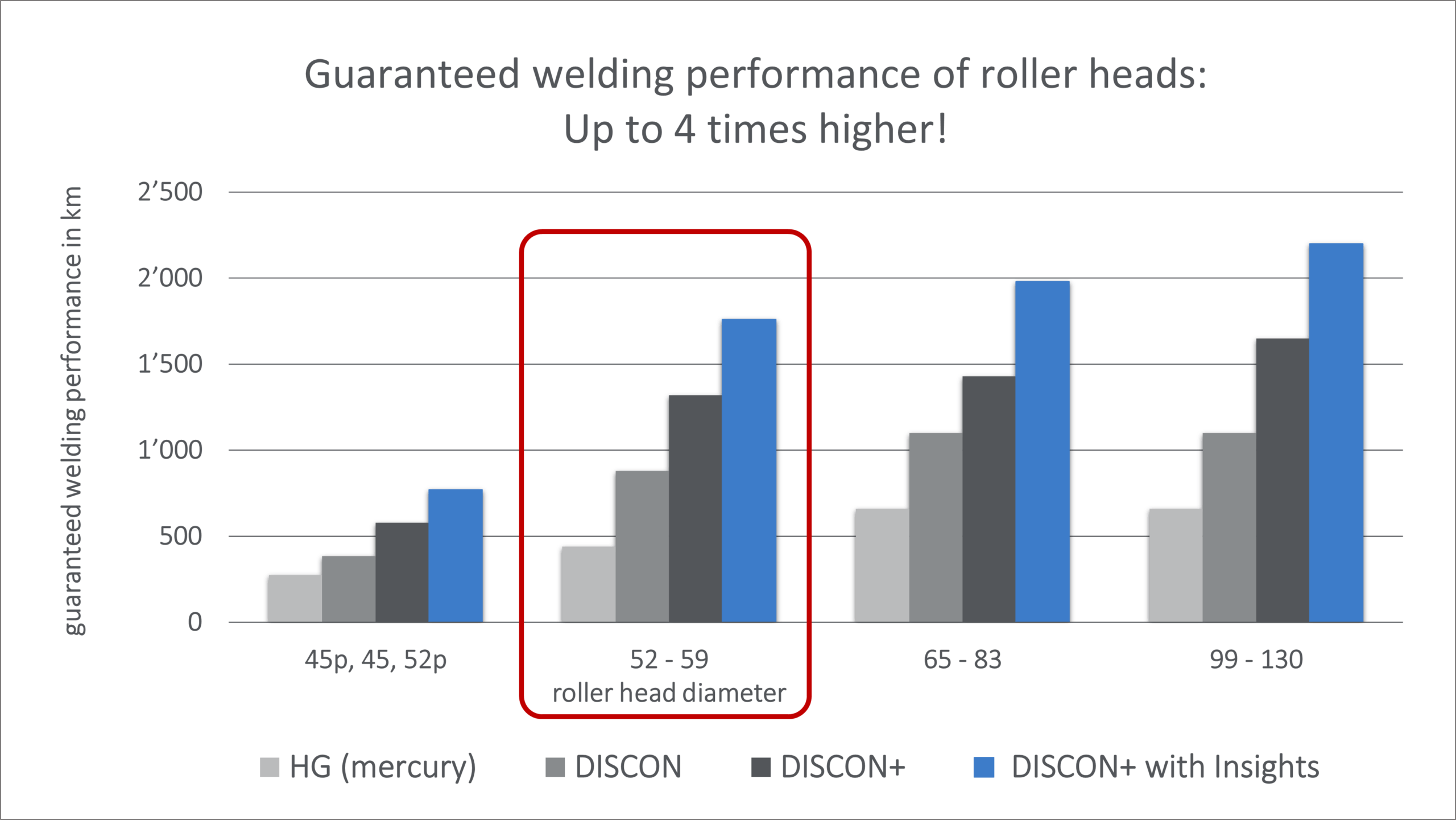

Up to 4 times higher welding performance!

Experience unparalleled efficiency and reliability with DISCON+, the latest generation of our renowned mercury-free roller heads for canbody welding machines. By using DISCON+ along with Soudronic Insights you’ll see a massive boost in guaranteed welding performance. When comparing the welding …

-

Full can decoration with PowerCOAT oP

Just launched a new product but unhappy with the visible welding seam? Choose the color from our new powder type that perfectly matches your canbody decoration. PowerCOAT oP allows the usually time-consuming change of powder color within 15 to 30 …

-

Our new Premium Conversion Packages

At Soudronic, we understand the longevity and efficiency of your can making lines is paramount. That’s why we’re pleased to introduce our Premium Conversion Packages, specifically designed to revitalize your aging equipment. With cutting-edge control and drive technology, these Premium …

-

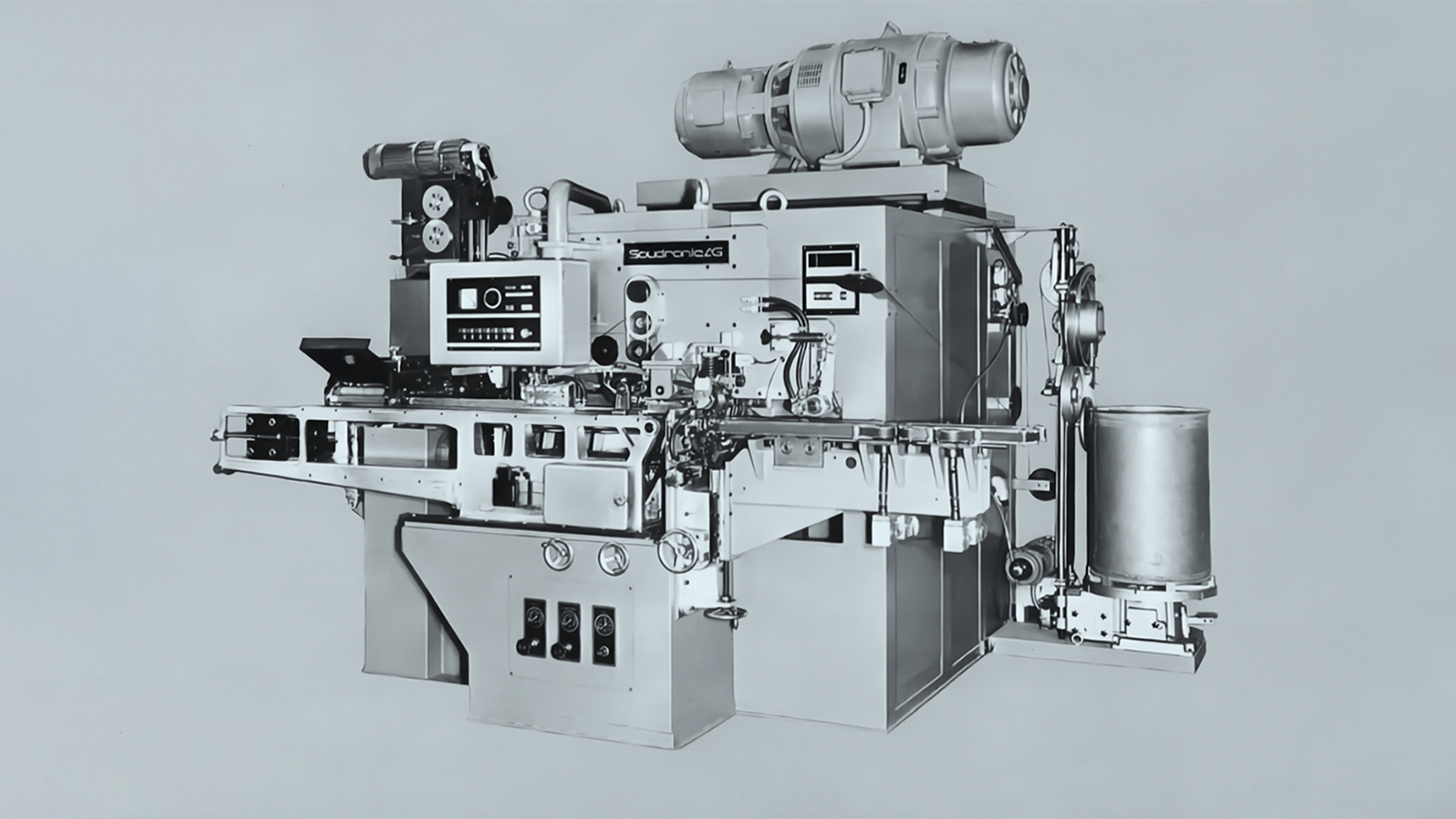

Phase-out of UNISOUD, upgrade to PULSAR

Since its development by Soudronic in 1992, the pioneering achievement of the static UNISOUD welding current converter has been in reliable operation in more than 1,500 welders. Due to increasing difficulties in sourcing the electronic components, Soudronic will phase-out the …

-

Phase-out ORC, DRC roller coating technology

Production of unit has been stopped because key components are no longer available. Since many electronic components used in older Frei AG systems are getting phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is …

-

mySoudronic – our brand-new customer portal!

We provide support for you and your operators anytime, anywhere, and on any device with mySoudronic, available from November 2023. This single point of entry offers a wide range of useful applications. Train your operators with Academy e-learning modules or …

-

Phase-out PCA, PCB and ECM, FCM gas curing systems

Production of unit has been stopped because key components are no longer available. As many electronic components used in older Frei AG systems are getting phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is …

-

Phase-out BPC, SPC powder (coating) systems

Production of unit has been stopped because key components are no longer available. As many electronic components used in older Frei AG systems are getting phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is …

-

mega24 Gewerbeausstellung Mutschellen

Soudronic strongly engages in the Swiss Vocational Education and Training for young people. Come and see our trainees presenting their professions at our booth C011 at the trade exhibition mega24 in Berikon, Switzerland from 11 – 14 April, 2024. Soudronic …

-

Anuga FoodTec 2024

Soudronic Group participated in the exhibition Anuga FoodTec, which took place from March 19 to 22, 2024 in Cologne, Germany. In a virtual presentation, we showed our turnkey can manufacturing systems. For more details about the exhibition, please refer to …

-

LATAMCAN in Buenos Aires

The Latin American Canmakers Conference took place from 17 – 19 April, 2024 in Buenos Aires, Argentina. We participated in the exhibition, and it was a pleasure to have visitors come and see us.

-

Season’s Greetings 2023

Enjoy watching our Season’s Greetings movie! We wish you a peaceful Festive Seasonand a Happy New Year. Wir wünschen Ihnen frohe Festtageund einen guten Rutsch ins neue Jahr. Nous vous souhaitons de joyeuses fêteset une excellente nouvelle année. Sinceri auguri …

-

Cannex Fillex Asia Pacific

We’re looking back on a successful participation at the world canmaking congress Cannex Fillex in Guangzhou, China from 16–19 July 2024. We introduced our brand-new welder COMPACT 240 that comes with unsurpassed Swiss quality at an unbeatable price-performance ratio. Its …

-

Phase-out APC, EPC, LPC – Last call

End of life: June 2024. Our supplier is phasing out many electronic components used in older Frei AG systems. To secure the function and avoid a loss in production, we strongly recommend having the ACP, EPC, LPC powder units converted. …

-

Offices closed for holidays and contact details of on-call team

Please be informed that our offices will be closed from December 23, 2023 until January 2, 2024 in observance of the Christmas holidays. Normal operations will resume on January 3, 2024. Our on-call team is available on a selected number …

-

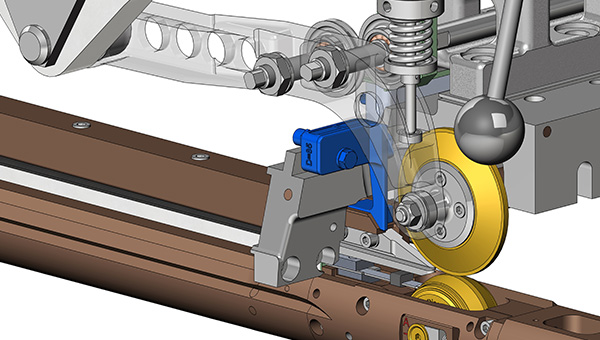

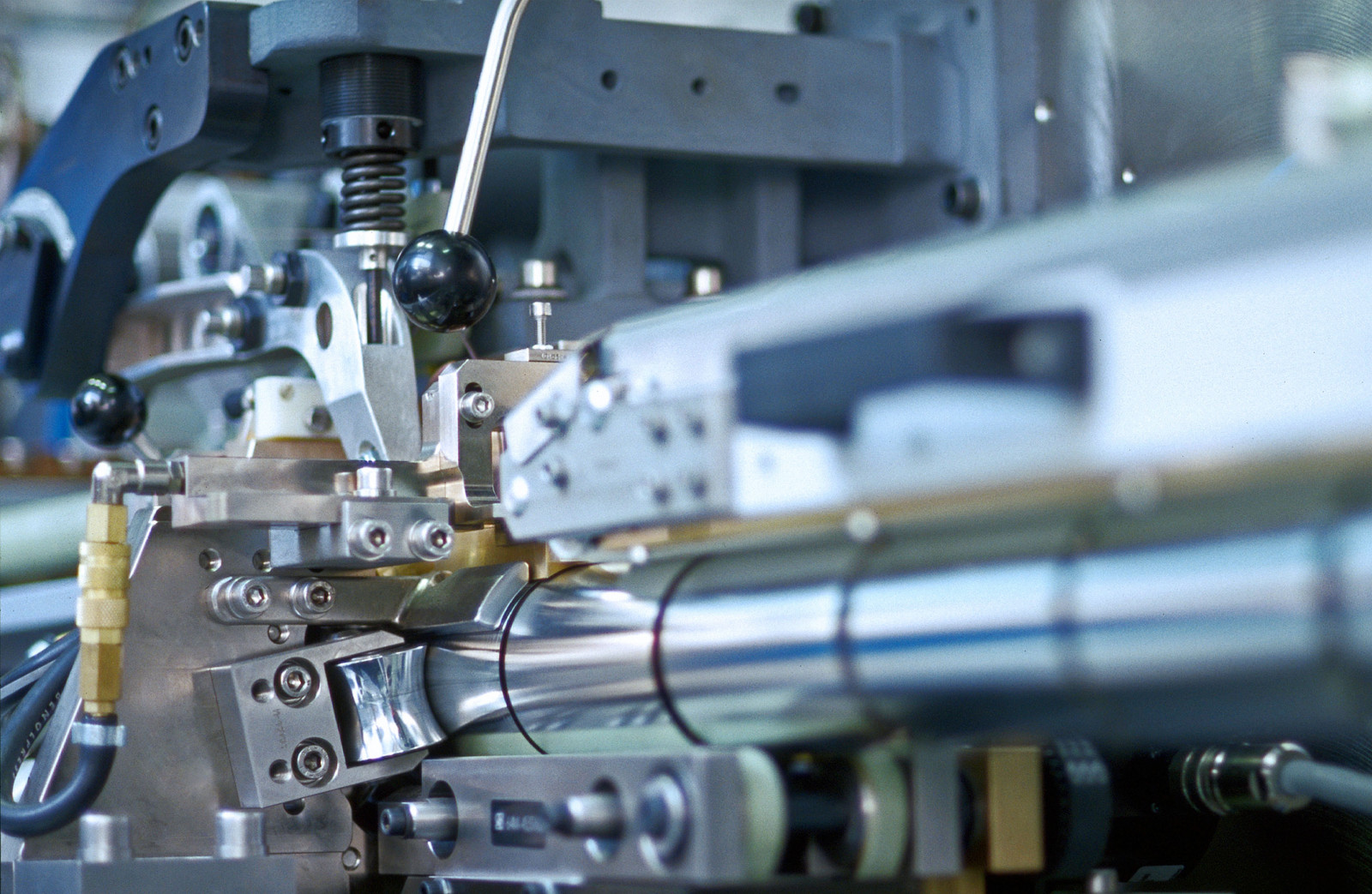

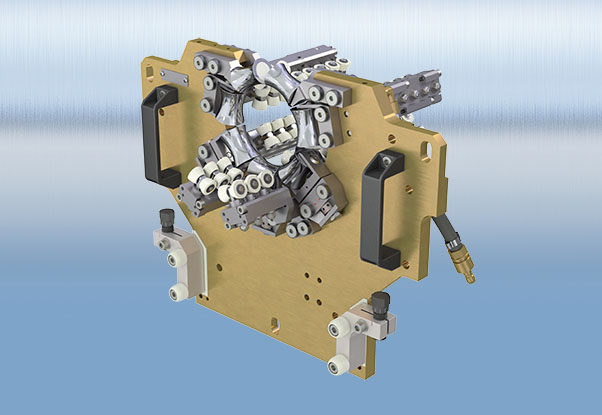

DISCON+ a masterpiece of engineering

Watch our video and find out more about the advantages of our new DISCON+ roller head. DISCON+ is the latest generation of our famous mercury-free roller head for can body welders. It is a true masterpiece of engineering and the …

-

Phase-out UNICONTROL 1: LAST CALL

Soudronic will phase-out UNICONTROL 1 by April 2024. As technology advances, some components of UNICONTROL 1 control units have been phased-out by our sub-supplier. To ensure functionality and prevent a loss in production, we strongly advise converting the equipment that …

-

Official product launch of DISCON+

The new DISCON+ roller head: Official product launch on 1 July 2023! With the new DISCON+ roller heads, we are improving the already renowned high quality and reliability, with improved key components, a new welding arm interface D-Lock (option) and …

-

Phase-out of UNISOUD, upgrade to PULSAR

Soudronic will phase out the UNISOUD converter by June 2025. Upgrade to the latest welding current technology and benefit from all advantages of the new PULSAR, the direct replacement. Since its development by Soudronic in 1992, the pioneering achievement of …

-

Gulfood Manufacturing Dubai 2023

Soudronic Group participated in the Gulfood Manufacturing Food Tech Show, which took place from November 7 – 9, 2023, at the Dubai World Trade Centre. This event offered a glimpse into the future of food technology and manufacturing, showcasing the …

-

Phase-out from PCE or UNICOAT, upgrade to SOUCOAT P-60S or SOUCOAT P-120S

Soudronic will phase out the PCE or UNICOAT by June 2026. Upgrade to the latest powder coating technology. Soudronic developed the PCE powder system in 1988, which was renamed UNICOAT in 2002. The system was sold until 2005. Due to …

-

APC, EPC, LPC – Conversions to PowerCOAT technologies

Soudronic will phase-out the APC, EPC, LPC by June 2024. As many electronic components used in older Frei AG systems get phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is ever increasing. This is …

-

Thank you for visiting us at Metpack

After six years we had the chance to welcome our customers and prospects at Metpack. Around 6,500 trade visitors from all parts of the world visited the world’s leading trade fair for the metal packaging industry, that took place from …

-

Launch of new website

We’re proud to announce the launch of our new website! And there’s more than just a new look: All five brands of the Soudronic Group have now been integrated in one website. The complete product offering of Soudronic, Sabatier, Ocsam …

-

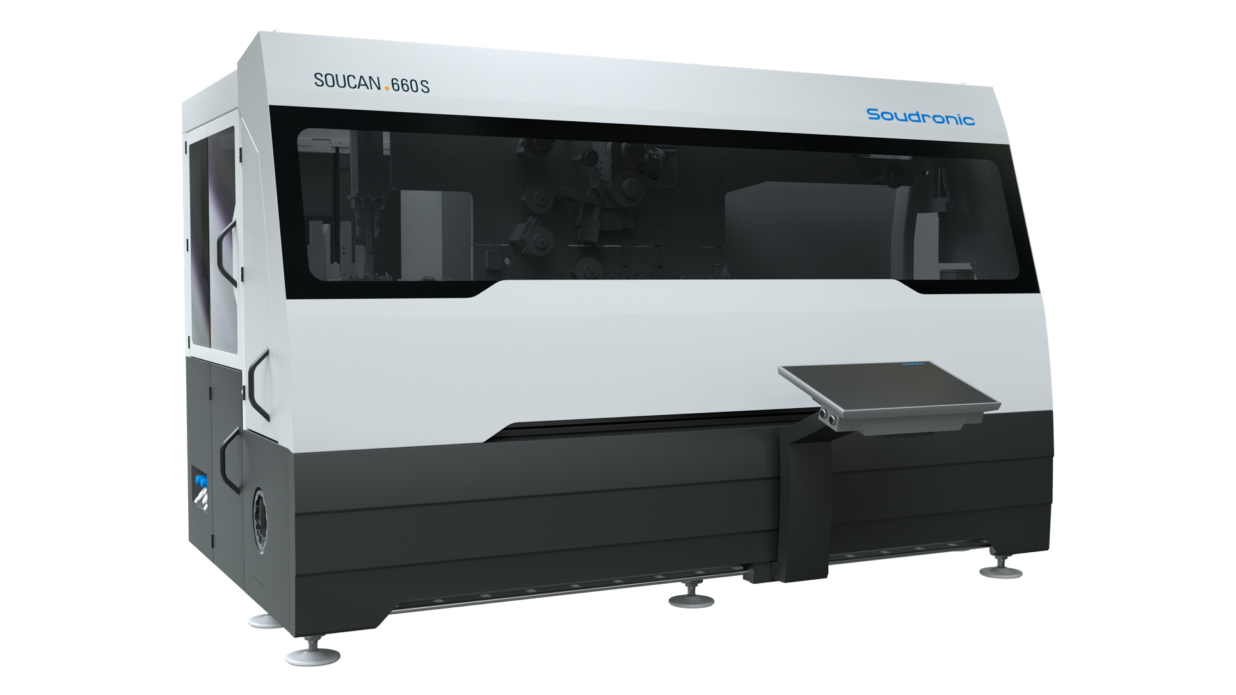

The new SOUCAN 600 S

With the new SOUCAN 600 S series we are introducing a new canbody welder generation. The best proven and successful features and technologies of the entire Soudronic portfolio are combined in this new welder. Customers can rely on a robust …

-

Soudronic Food Safety Standard

Over the last two years the Soudronic Group has developed the Soudronic Food Safety Standard in collaboration with an accredited Swiss laboratory. This unique standard is intended for the “basic hygiene” production section, where there is no direct contact with …

-

Successful Service Technicians Meeting

Four years after the edition 2019, and one year later than originally planned due to the COVID pandemic, Soudronic had the great pleasure to welcome a large team of field service technicians at our headquarters in Bergdietikon for the STM …

-

Season’s Greetings 2022

Watch our Season’s Greetings movie! We wish you a peaceful Festive Season and a Happy New Year. Wir wünschen Ihnen frohe Festtage und einen guten Rutsch ins neue Jahr. Nous vous souhaitons de joyeuses fêtes et une excellente nouvelle année. …

-

Top Employer 2022

We are proud to announce that Soudronic has won the award for Top Employer 2022 in the category 250-999 employees. This spring Soudronic took part in a Swiss employee survey with around 180 other companies and reached the first place …

-

A 30-year success story – UNICONTROL

Back in the early 1990s, Soudronic began developing its AFB/FBB series. Designed to weld an unprecedented 1000 can bodies per minute, the machines placed enormous demands on control system response times and processing speed and outstripped the capabilities of all …

-

Monitor Tap SOUCAN

New, more robust, silicone-free design. Customer benefits Retrofitting

-

Gulfood Manufacturing Dubai 2022

Soudronic Group has once again participated in the Gulfood Manufacturing Food Tech Show, that took take place from November 8-10, 2022 at the Dubai World Trade Centre. We welcomed visitors and customers at the booth of our partner Techno Middle …

-

Phase-out of UNISOUD, upgrade to PULSAR

Soudronic will phase out the UNISOUD converter by June 2025. Upgrade to the latest welding current technology and benefit from all advantages of the new PULSAR, the one-to-one replacement. In 1992, Soudronic developed the static UNISOUD welding current converter, a …

-

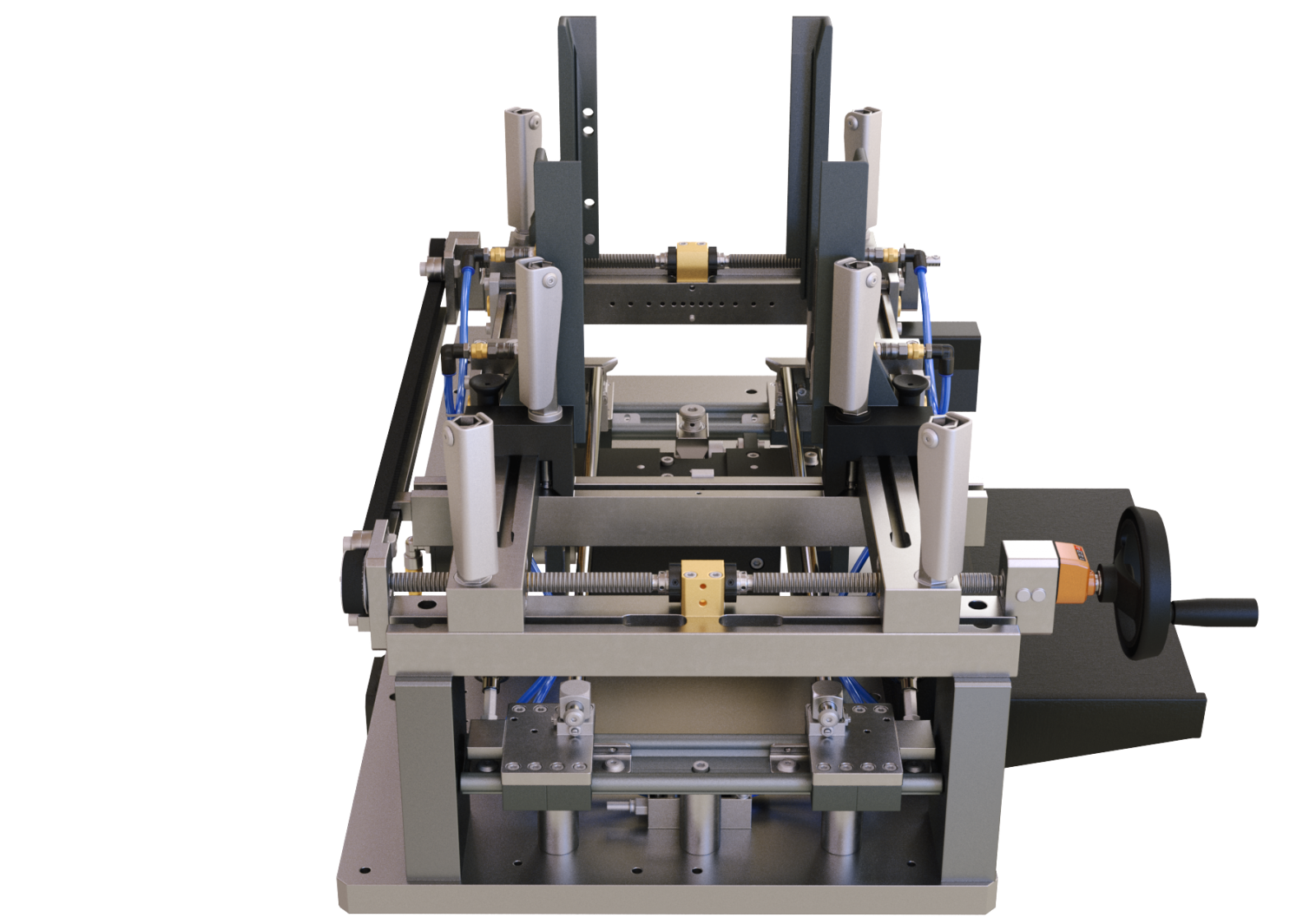

Easy adjustable destacker for fast change over

Body Blank Height changeover time is becoming increasingly important. With the new Easy Setup Feeder Magazine, a fast BBH changeover without the use of any tools brings more efficiency for canmakers. Advantages Retrofitting

-

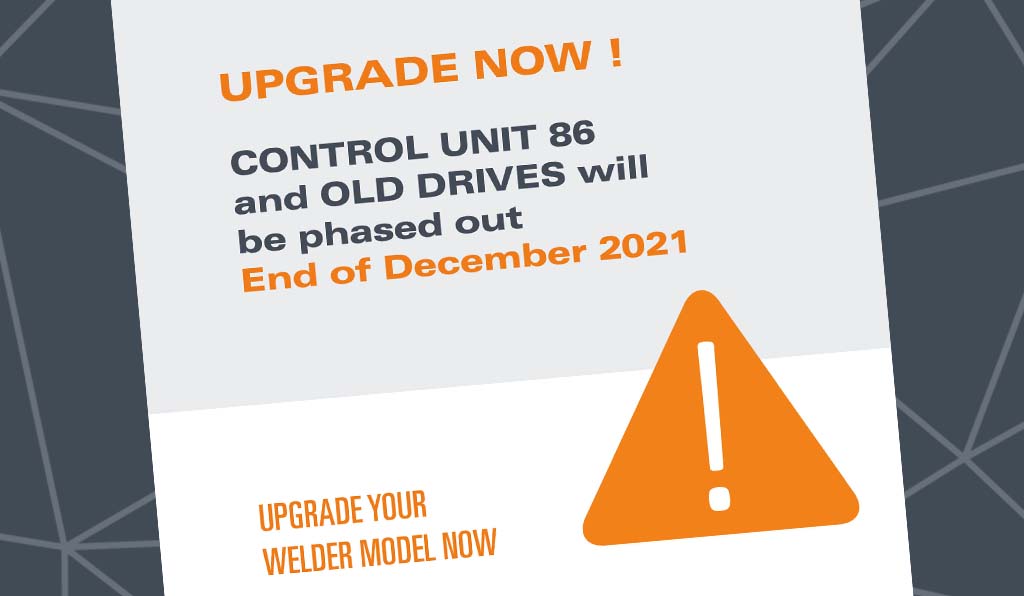

Control Unit 86 and old drives will be phased out

BWM 2000 / BWM 2100 / BWM 2200 (NORMA)MWM 6000 / MWM 6100 / MWM 6200 (CORONA) CONSIDER THAT … The average availability and support of general industrial controls is around 15 year. Soudronic has been supporting machines which are …

-

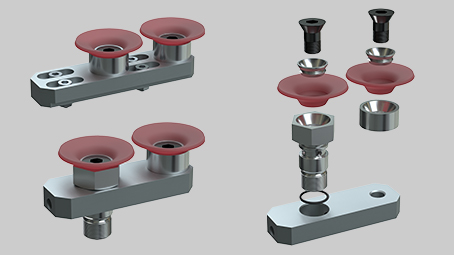

Advanced Suction Cup

New, economic suction cup for destacker of AFB 200/600 and SOUCAN 100 – 760 With this new development Soudronic launches an economic suction cup for the destacker that features an increased life time for low and medium range machines at …

-

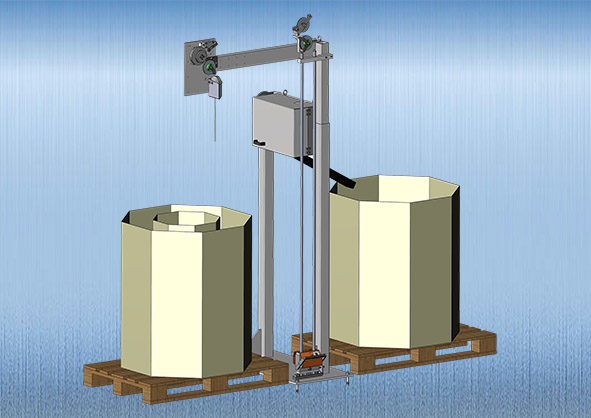

New machine: UNISEAL HSS-SL

For canmakers requiring low to medium production volumes of peel-off ends, the new single-lane heat sealing system UNISEAL HSS-SL is the perfect solution. The machine is available now and comes with a wealth of convincing features! The new UNISEAL HSS-SL for …

-

DISCON price reduction

Soudronic’s DISCON roller heads have been proven for decades as the reliable process solution for can body welding. Soudronic has constantly been working, since its market introduction, on developments and improvements on the DISCON system. Soudronic also has invested heavily …

-

DISCON

State-of-the-art roller heads for welders From 2020, all products are to be changed over to mercury-free substitutes. With our DISCON roller head we offer you a mercury-free alternative that has already proved its worth for many years. Start today in …

-

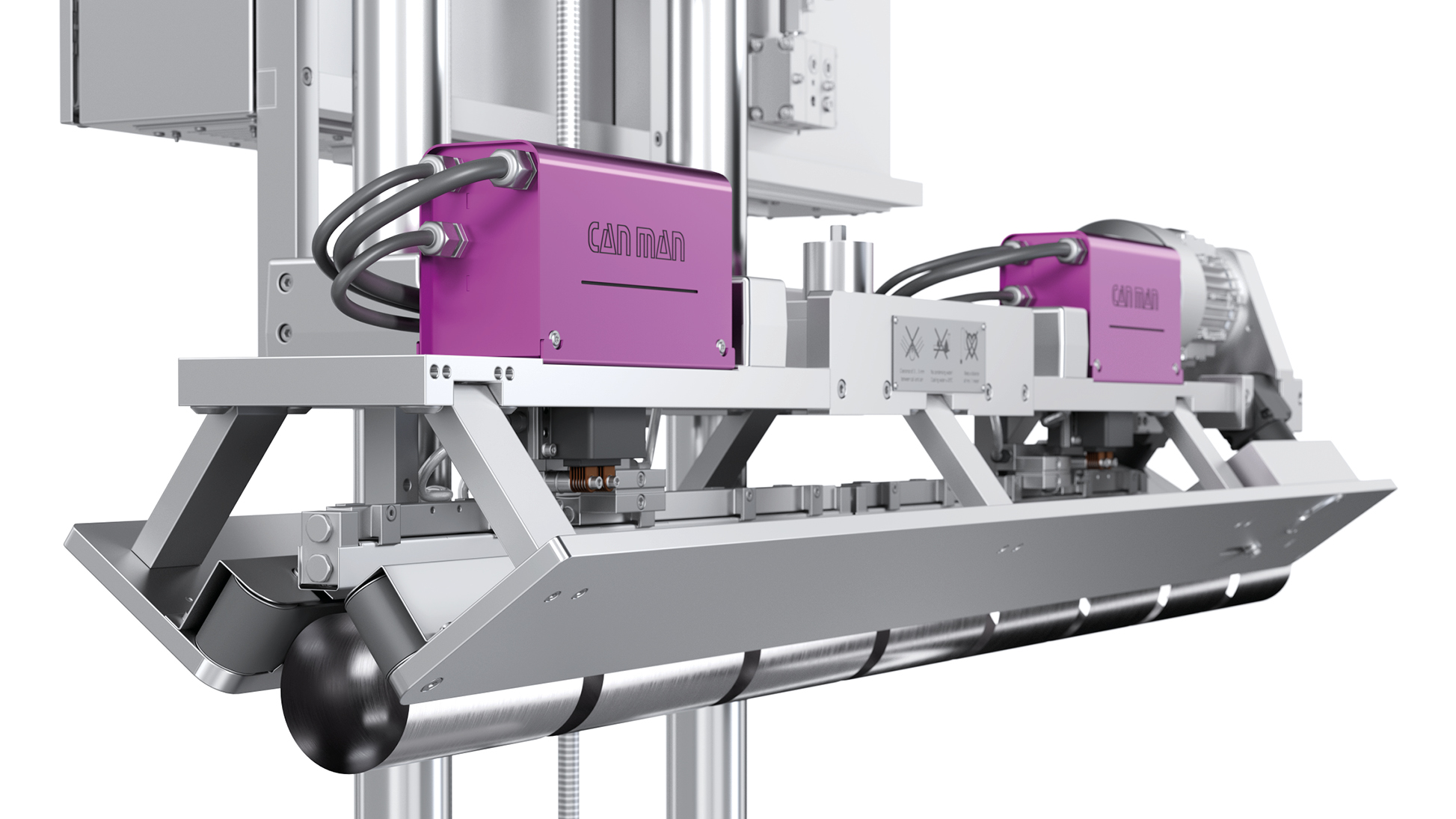

Cooperation Soudronic AG and Can Man AG

Cooperation Soudronic AG and Can Man AG We are proud to announce that Can Man AG together with Frei AG are new members of the Soudronic Group. Mr. Ruedi Umbricht together with his sister Marianne und his brother Johnny have …

-

CT-3 Cone Tester

The CT-3 Cone Tester is used for testing the conical expansion of the can bodies at the leading and trailing ends. Model name CT-3 Cone Tester Sheet thickness 0.14 – 0.50 mm Can-body diameter 45 – 330 mm Can-body height …

-

OSS Lacquer Temperature Control

Fluctuating ambient temperatures affect lacquer viscosity and have a negative effect on the coating quality. By controlling the temperature of the lacquering gun (cooling and heating), the lacquer temperature can be precisely regulated (+/-1°C) regardless of the ambient temperature. Using …

-

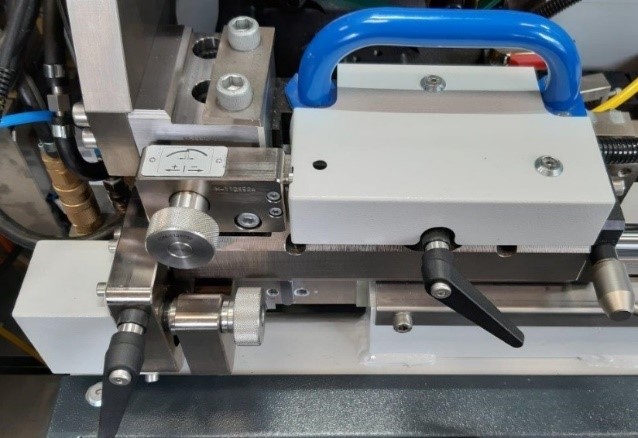

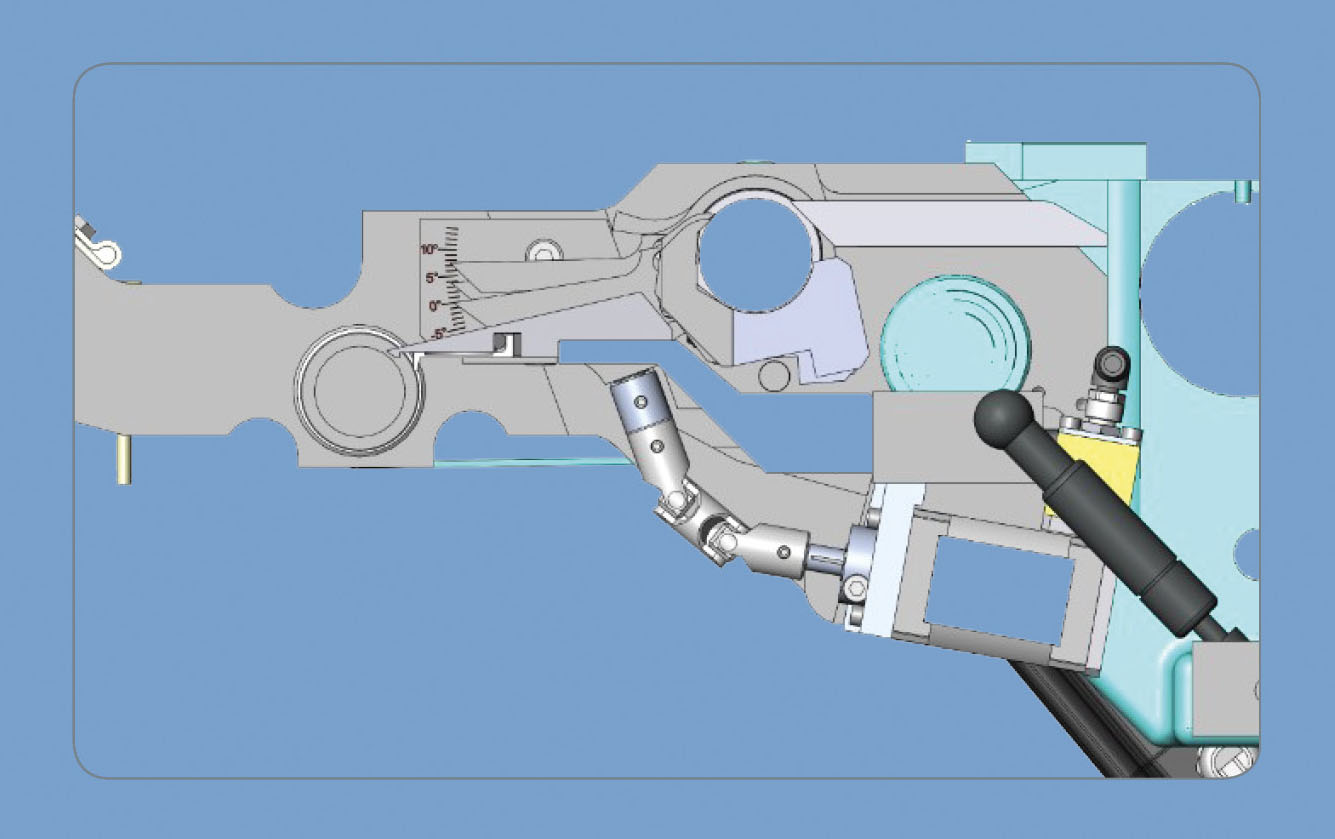

UNITOOL with easy setup

The UNITOOL setting positions have a direct influence on the welding quality. Therefore, these positions must be set very precisely when changing formats and tools In order to achieve even greater efficiency when changing formats and tools, the tool height, …

-

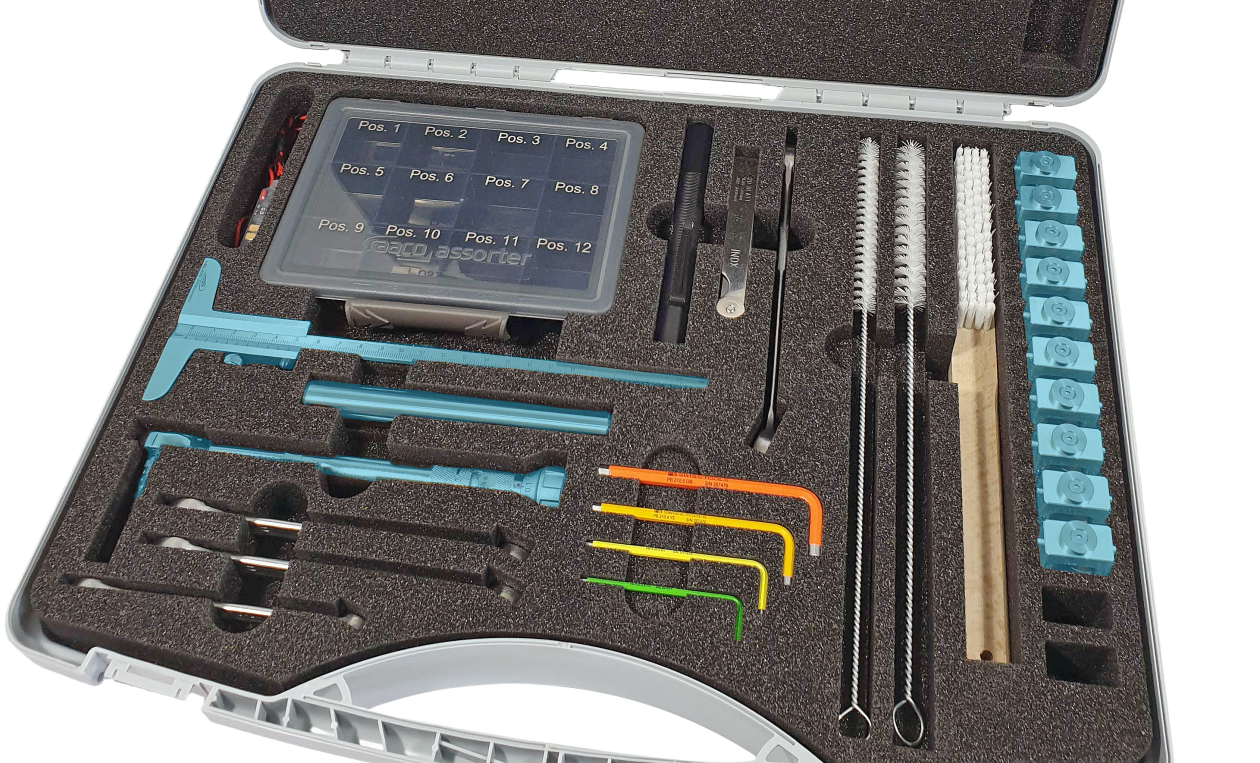

Tool box for refinishing and aligning roller heads

Maintenance is much easier with the roller head service kit. In the Roller Head Service Kit, the customer has all required tools and spare parts at hand for the roller head maintenance. Efficient refinishing and alignment of the roller heads …

-

Difference in the detail – Lightweight rigidity

The art of not falling flat on your face Despite their oversized bills, toucans don’t keel over. Equipped with serrated edges that are perfect for tearing fruit, their beaks are surprisingly light and, thanks to a complex structure, extremely tough. …

-

Keeping a cool head

Difference in the Detail – Thermoregulation Animals have evolved many ways of staying cool. Jackrabbits have enormous ears with exposed blood vessels that dissipate heat and keep their body tem-perature within reasonable limits. Overheating is also a problem for resistance …

-

Fast, reliable customer support worldwide

Service Technician Meeting at Soudronic at the beginning of this year Customer support, as we understand it, is not only a global but also a lifelong commitment. Soudronic can be really proud of this picture. It shows the importance that …

-

Stand-alone DSA wire chopper

Wire break safety device for DSA with stand-alone wire chopper More space and flexibility in line layout design. The drum with the copper wire shreds can be positioned according to layout requirements thanks to the new option. The wire chopper …

-

SOUCOAT – FDC-1000 COMPACT

Automatic filter cleaning during production guarantees a continuous and uninterrupted powder seam coating and increases the efficiency of the production plant. The installation of a bypass system in the FDC recycling unit enables continuous filter cleaning during production, thereby preventing …

-

Calibrating Force Monitor

Thanks to the new Calibrating Force Monitor, all welding-related influences can be detected. Soudronic engineers have reached another major milestone that will boost production reliability in welding technology. So far cold welds caused by overlap errors could not be detected. …

-

Welding Roller Dressing Unit VS-30

Reliable, safe and clean: the welding roller dressing unit VS-30 leaves nothing to be desired. A perfect roller head quality is the basis for a safe and efficient welding function. Therefore, it is a fundamental condition that the groove geometry …

-

UNIPROFILER

Motor-driven regulation of wire width for the wire profiling unit. Constant wire width – measured and corrected in real time Tedious measuring and manual correction no longer necessary. Meeting requirements despite ever-increasing quality standards As machines become faster and faster, …

-

Soudronic welder – Easy setup

An easier format change is hard to imagine. Feeder settings Quick reproducible format settings are the key to high-efficiency machines. Easy and time-saving In order to ensure trouble-free sheet separation, the feeder settings must be reproduced very precisely. With the …

-

Rounding measuring device (SRM)

Soudronic now offers the diagnostics functionality of the Adaptive Rounding System (ARS) as an individual feature under the name Soudronic Rounding Measuring Device (SRM). Cost pressure is forcing canmakers to increase line efficiency. The demands made of machine operators are …

-

UNICONTROL 3 with new, integrated CAN bus and I/O diagnosis

The new feature allows rapid diagnostics without the need for auxiliary equipment on the UNICONTROL screen. Diagnosis of CAN bus problems is usually difficult without the help of an experienced specialist because the necessary measuring instruments are not available. The …

-

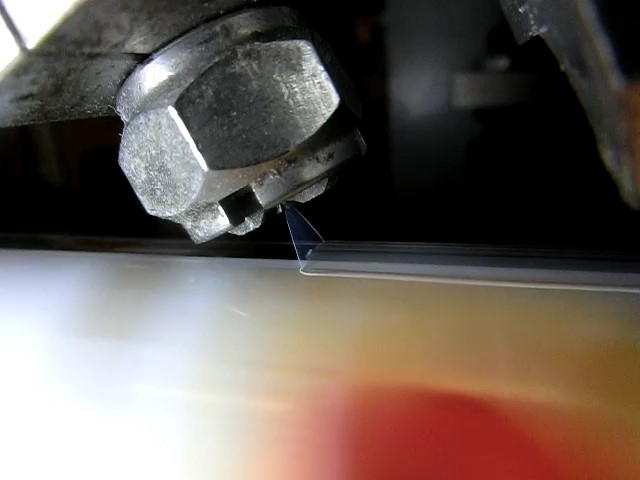

Seam temperature control boosts product quality

As the demand for greater all-round can quality increases, the packaging industry needs more effective production monitoring. One area of the manufacturing process crucial to quality is seam coating control. Fortunately, it is now a simple task to make vital …

-

Tool II

New version of the standard tool The latest generation of our standard tool is configurable for various requirements. In its simplest form, it is ideal for cost-effective sample production but can easily be modified for more exacting requirements. Retrofitting is …

-

Motorized flexer setting system MFS

The new option allows for faster, more precise adjustment of the flexer unit. Flexing precuts the rounding and is thus an important part of the rounding process. By drawing on empirical values obtained over many years in tough production environments …

-

SOUCURE G – Gas burner with stainless steel burner tube

Corrosion-resistant burner tubes can be used to prevent corrosion caused by lacquer condensate, humidity, and oxidization as a result of thermal stress. Using corrosion-resistant materials eliminates material oxidization inside the burner tube, guaranteeing a continuous burner function and reducing the …

-

Tandem outside spray system for high-end production requirements

The tandem OSS was developed with a view to improving weld seam quality. Having two OSS units increases the thickness of the lacquer layer and protects the weld seam effectively against corrosion. Certain market regions and segments require increased protection …