Seam temperature control boosts product quality

As the demand for greater all-round can quality increases, the packaging industry needs more effective production monitoring. One area of the manufacturing process crucial to quality is seam coating control. Fortunately, it is now a simple task to make vital functions visible to the operator.

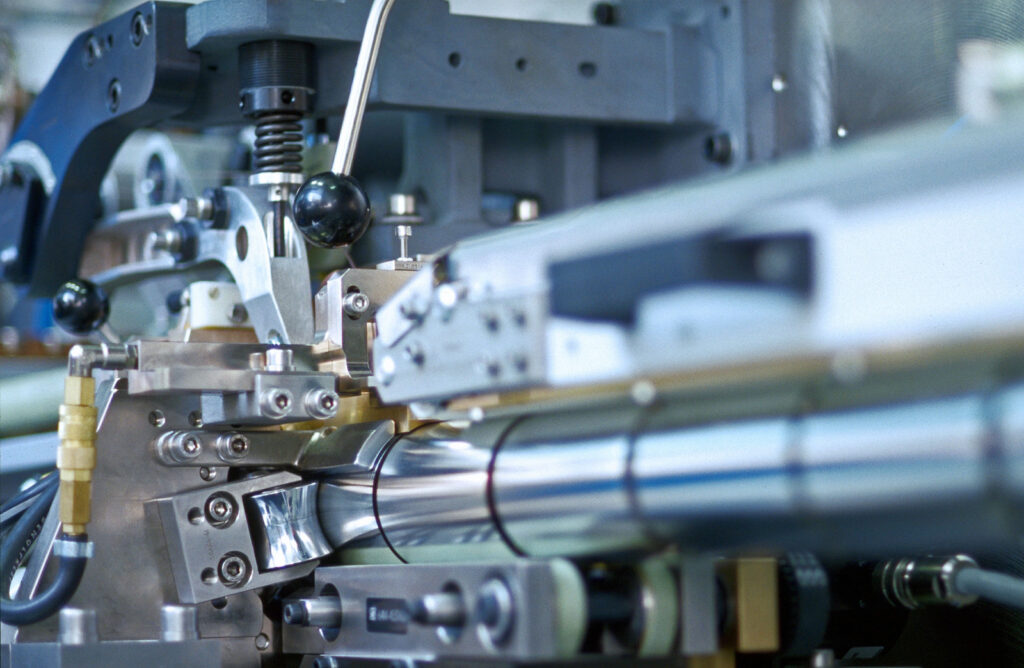

A temperature-monitoring sensor positioned at the end of the gas-curing tunnel and connected to the UNICONTROL unit provides the machine operator with essential information about the seam temperature of can bodies as they emerge from the oven. The operator can use this information to establish whether the correct setpoint temperatures for seam coating have been reached. If this is not the case, he can make the necessary adjustments in the heating area.