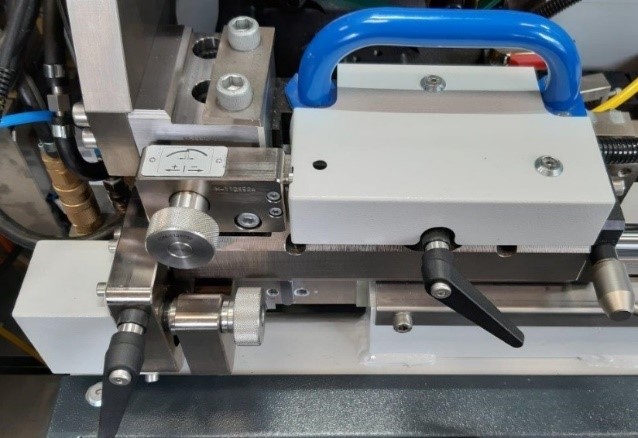

UNITOOL with easy setup

The UNITOOL setting positions have a direct influence on the welding quality. Therefore, these positions must be set very precisely when changing formats and tools

In order to achieve even greater efficiency when changing formats and tools, the tool height, tool diameter and the position of the tool in front of the welding plane are now detected by sensor. This makes it possible to read the set tool positions directly on the HMI.

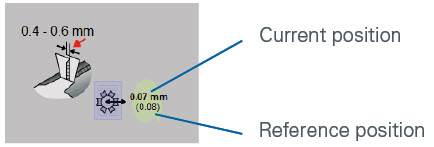

In addition to the current position, a previously saved reference value is also displayed. This supports the operator when changing formats or tools and must only be saved manually once. The reference value is stored in the data record.

Advantages:

- Maximum reproducibility thanks to storable positions and display on the HMI

- High positioning accuracy thanks to sensor-based position detection

- Efficient setup and conversion thanks to the position indicator on the HMI

Retrofitting: Retrofit for UNITOOL only.

- SOUCAN 800/1000/2000 AF/FB from LA-425550

- SOUCAN 700 from LA-425560

- SOUCAN 600 from LA-425570

Retrofitting for other machines and stock orders on request. (feasibility study)