DISCON

State-of-the-art technology for welders

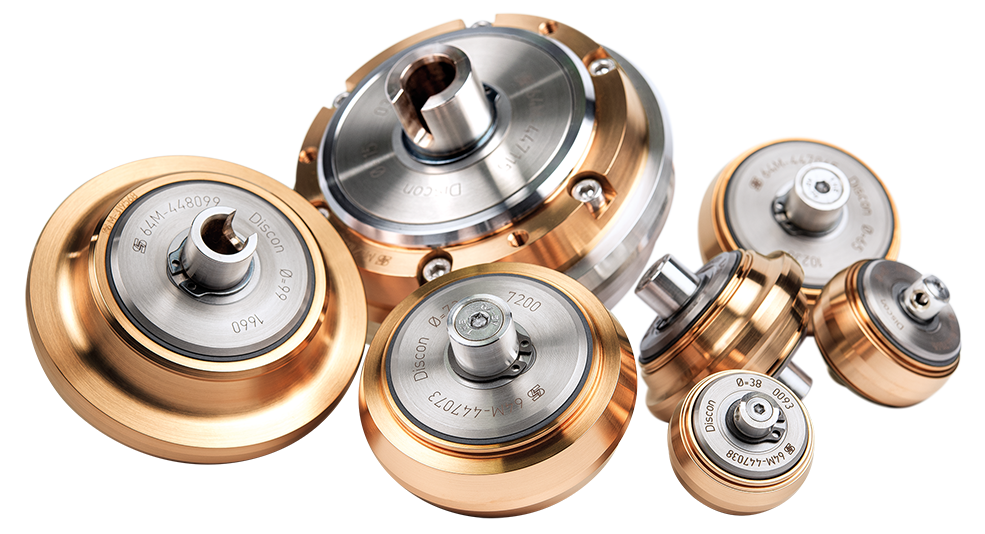

DISCON+

DISCON+ is a masterpiece of engineering, it is 100% manufactured with highest precision at Soudronic’s headquarters in Bergdietikon, Switzerland.

With the new DISCON+ roller heads, we are improving the already renowned high quality and reliability, with improved key components, a new welding arm interface D-Lock (option) and a complete new digital performance dashboard roller head-ID+.

The result of all these improvements is a better groove life, which means that the DISCON+ roller head needs to be redressed less often and the lifetime is increased. In combination with the new D-Lock interface and the optimized and matched sealings in the DISCON+ roller heads, a new level of food safety has been reached and the lifetime of the roller head is further extended.

Advantages DISCON+

- Increased lifetime through improved components

- Better groove life, less redressing

- Highest reliability

- Better food safety with mached seals

- Quality test of all components

- All roller heads are tested under current

- Available as O-Lock and D-Lock

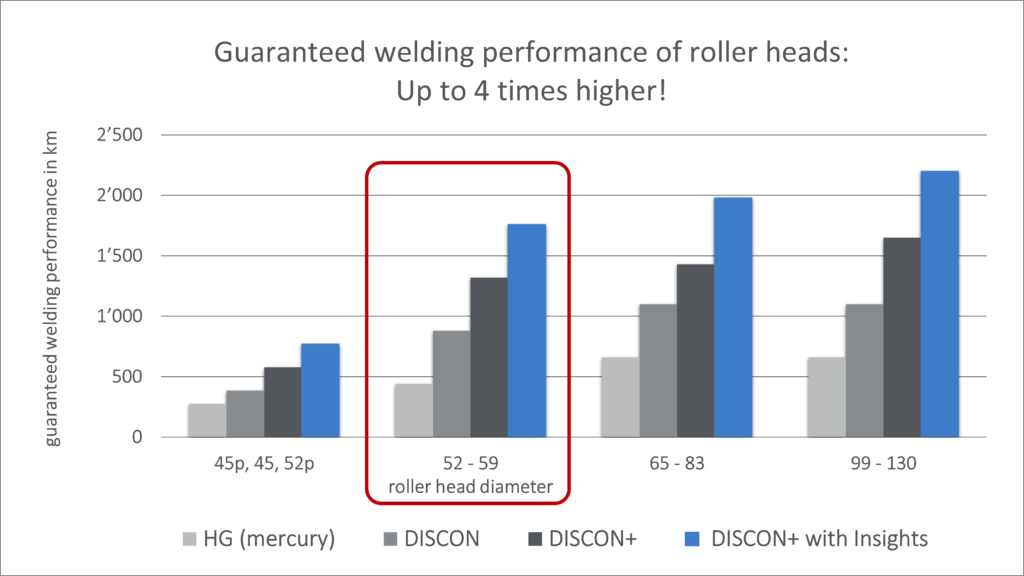

Guaranteed welding performance increased to up to 4 times!

The roller head performance is indicated in welding kilometers, which allows a better comparability of different can formats. Benefit from a significant increase of the guaranteed welding performance in kilometers by using Insights from mySoudronic.

When comparing the welding performance of a DISCON roller head size 52 to a DISCON+ and using Insights, the guaranteed welding performance doubles! It even increases to 400% when comparing a mercury (HG) roller head size 52 to a DISCON+.

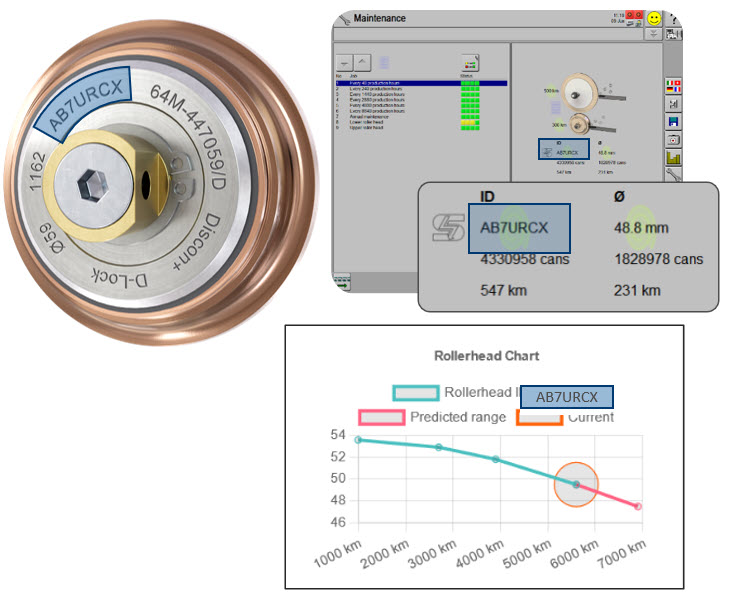

Roller head ID+

To also improve the workflow and make production-relevant data and settings with the roller head visible automatically, every DISCON+ roller head is delivered with the roller head ID+. This makes it possible to automatically record and link all production-relevant parameters of the roller head, without manual input. This enables a statistical evaluation of all rollers and predict the next redress interval and the remaining runtime.

- Soudronic Insights ready

- Production data linked to roller head

- Roller head performance dashboard

- Easy accessible

- Statistical analysis

- Predicted lifetime and redressing

- Statistics and running times are exported directly (no running sheet required)

Get rid of mercury

With a conversion to DISCON, mercury as medium for transferring current from the stationary part to the rotating outer part of the roller head and welding roller is no longer needed. Sliding contacts replace the liquid-contact technology and makes the product environment-friendly and easily disposable. The circulated DISCON emulsion is an FDA approved coolant and lubricant for the DISCON roller head and welding roller.

Start today in a toxic-free future and convert to DISCON.

Upgrade to DISCON

- Easy to install by your own staff

- Easy to transport

- No cooled storage required anymore

- Improved production life

- Less condensation due to higher inlet temperature (25° C)

- Fits to your old machine without rework

- No liquid metal in your plant anymore

- Non-toxic production

- Safer production