APC, EPC, LPC – Upgrade packages due to phase-out of major components

06.2024 – End of life

Retrofitting

ACP, EPC, LPC powder units can be upgraded to most of the latest technologies in today’s Frei AG systems. Instead of investing in new lower quality equipment, you could perhaps consider modernizing your existing system now.

Advantages Premium Package:

- Latest high voltage systems with fully automated diagnosis. Compatible with existing cascades. Spray current measuring on every can.

- New PLC and Touch screen with extensive functions

- Availability of spare parts guaranteed for the next years

- Welding speed up to 100m/min

- No more manual settings, all values are set according to the stored recipes by proportional valves

- Ejector for less overspray and cleaner application

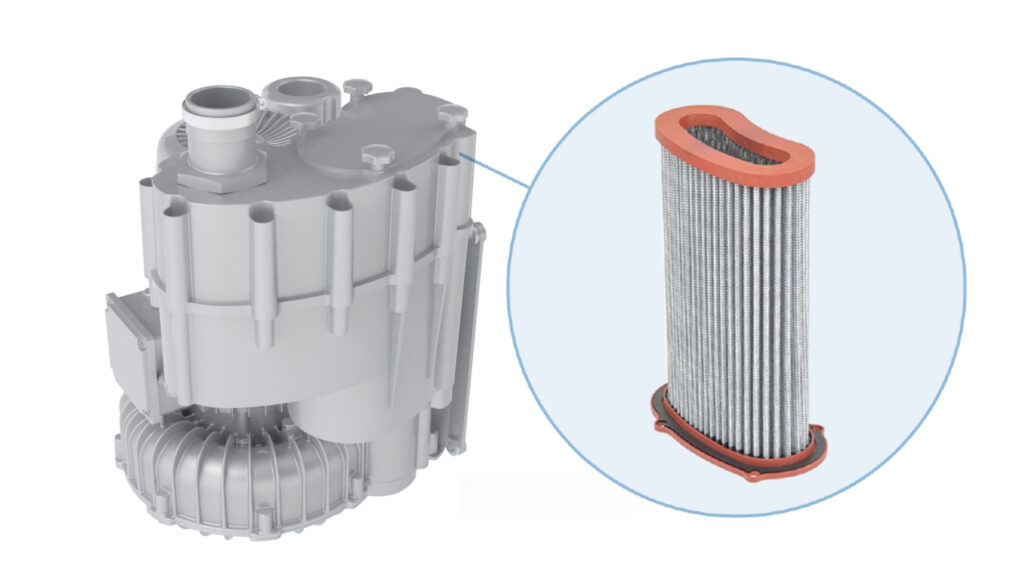

- Safety filter directly on frequency controlled vacuum pump

- Closing cylinder on coating injector for automatic cleaning of feeding tubes

- Powder monitor (option)

- Insights ready

Why upgrade?

As many electronic components used in older Frei AG systems get phased-out by suppliers, the need to adapt electrical systems to accommodate new equivalent replacements is ever increasing. This is the best opportunity to not only restore old functionality but to upgrade to the latest technologies.

Phase-out – Phase V: What does this mean for you?

- Repairs can no longer be guaranteed

- Order now: Upgrade to the latest powder coating technology

- APC, EPC, LPC is phased-out, end of life 06.2024

Major downtimes of production line are imminent!

Options available

- Various monitoring systems available

- Remote access

Conversion

Detailed product information on our latest product is available on the product page of PowerCOAT iP.