Accessories for Products and Lines

We provide a wide range of accessories suited for each process step of a can manufacturing system. Additional equipment and devices support and facilitate operations. Manual and electrical measuring instruments, monitoring and testing devices can be used to check and ensure the quality of the products during production and help to reduce machine downtime.

Accessories Slitter

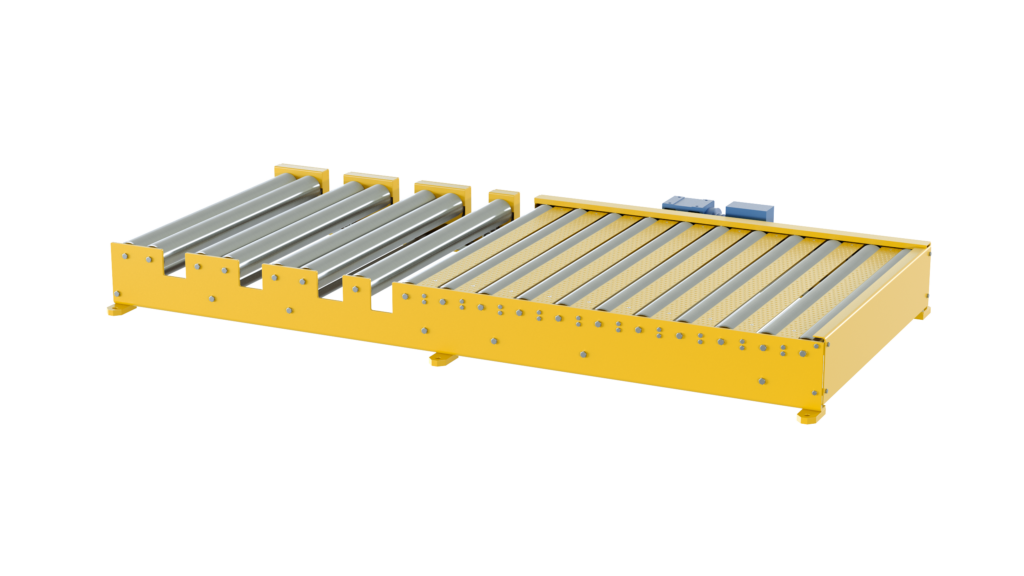

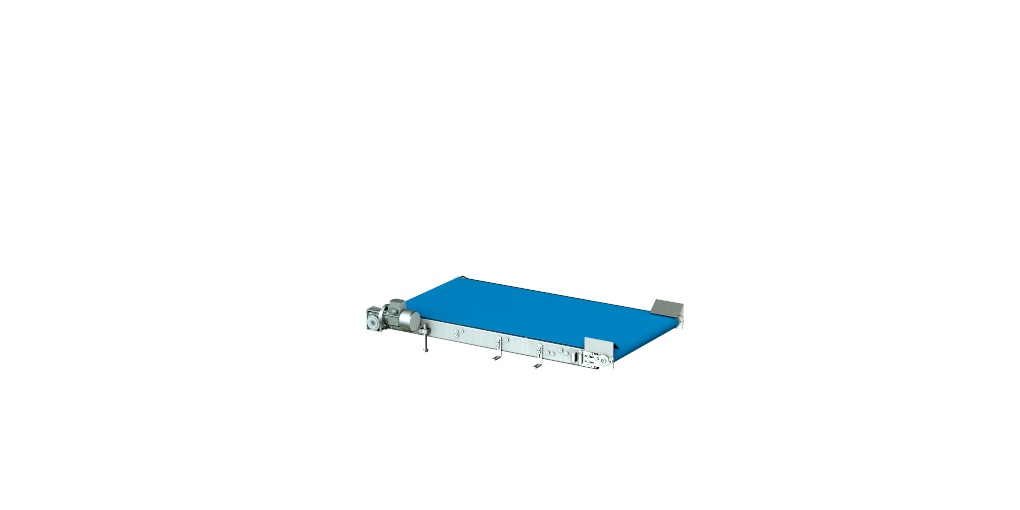

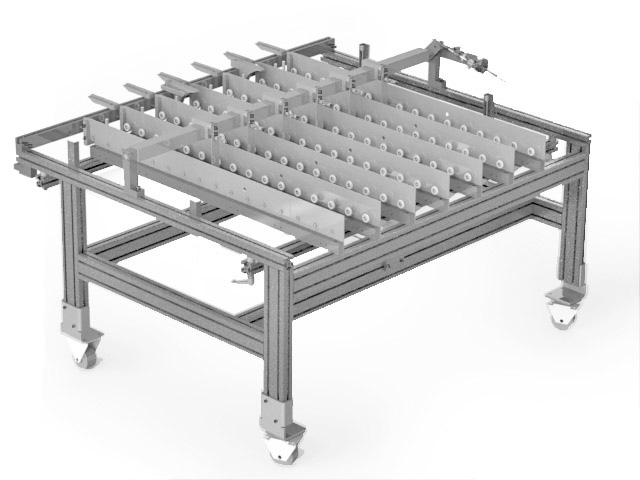

Driven roller conveyor

The most attractively priced solution to feed the pallets of sheets easily into the slitter.

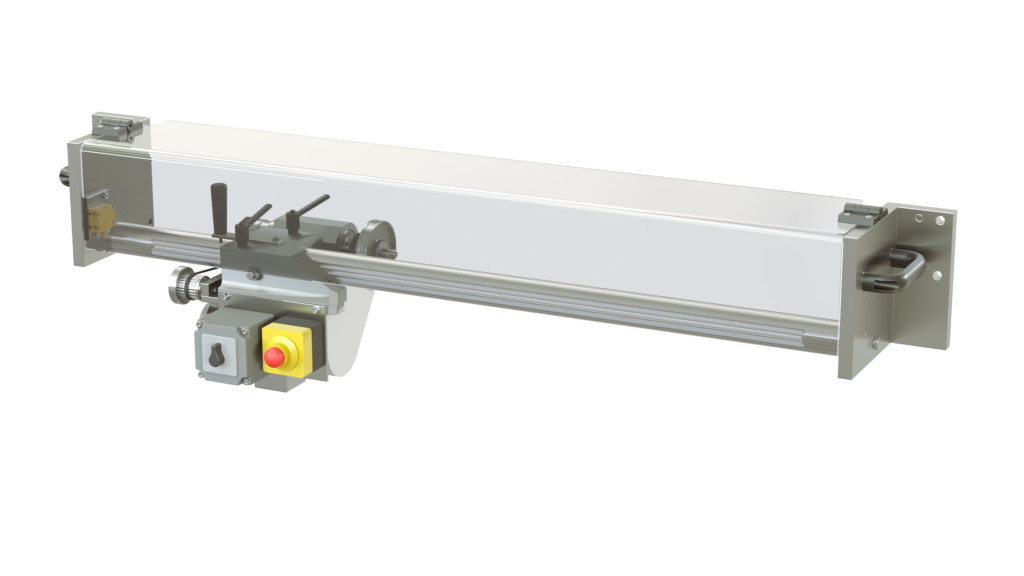

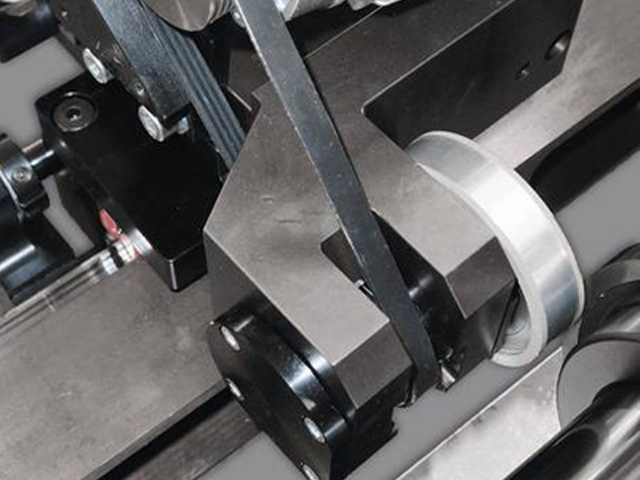

Roller cutters grinder

This is a must to keep the roller cutters in good condition. The grinding operation should be done at least once a year to avoid burrs and bad cuts. To perform the grinding operation, this unit can be mounted on the frames of the slitter (1st and 2nd table) to grind the roller cutters in the position where they are.

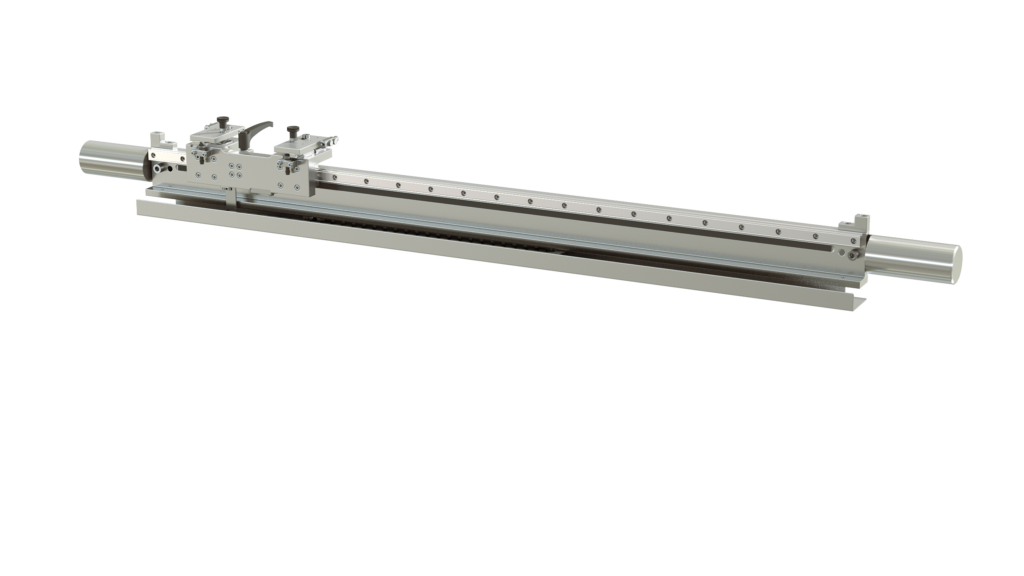

Digital measuring device to adjust roller cutters

For a rapid and precise positioning of the roller cutters.

Can be integrated in the control of the slitter on TSN and SGS slitter or stand alone unit for any other Ocsam Cepak slitter.

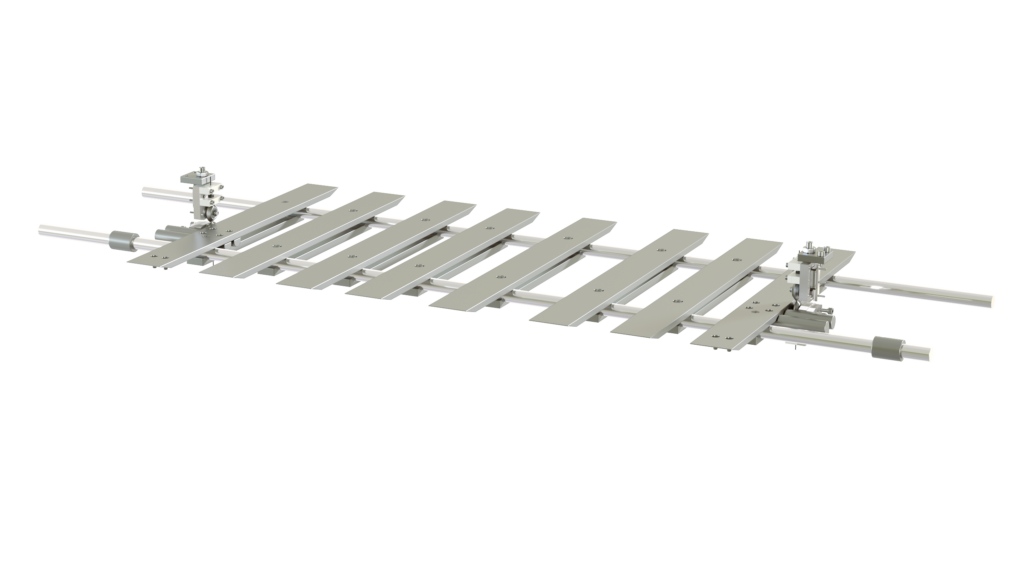

Margin Control

The best solution to check on the slitter if the lithography is in line with the sheet. It is checking at the exit of the 1st table if both sides of the sheets are free of lacquer.

NTR 800 scrap conveyor width 800 mm

First cutting operation with standard knifes without trim cutters / Big8 or

Second cutting operation with lift-table blank collector.

NTR 300 scrap conveyor width 300 mm

First cutting operation with standard knifes in combination with trim cutters or

Second cutting operation with blank collector.

NTR 800L linear scrap conveyor

Linear scrap conveyor width 800mm

Digital roller cutter adjusting unit

To adjust the roller cutters precisely and within shortest time we provide a digital roller cutter adjusting unit which can be mounted on the slitter. For first and second cutting operation, depending on the type of knives being used.

Cutter grinding

The accuracy of the cut blanks highly depends on the status of the roller cutter knives. To avoid unprecise cutting and burrs, a semiannual or annual sharpending of the knives is a must. Best to be done with a precise and easy to use grinding unit.

Body Blank Measuring BBM 1250

A good can starts with a good blank. To do important offline controls we provide the Body Blank Measuring BBM 1250 unit to ensure that cutting tolerances are kept within the limits.

Driven roller conveyor

The driven roller conveyor can be placed in front of the slitter to place ready to be cut sheets with a forklift. The pallet is transported by a driven roller system into slitter’s downstacker.

Accessories Transfer

Ocsam Cepak TPM / TPM-S

Removable and adjustable blanks cassette

Recommended one adjustable cassette for each diameter to speed up the diameter change.

Ocsam Cepak TPM / TPM-S

Removable and dedicated blanks cassette

Recommended a dedicated cassette for body blanks height <75mm, to speed up the change over with small blanks.

Can Man PowerFEED S

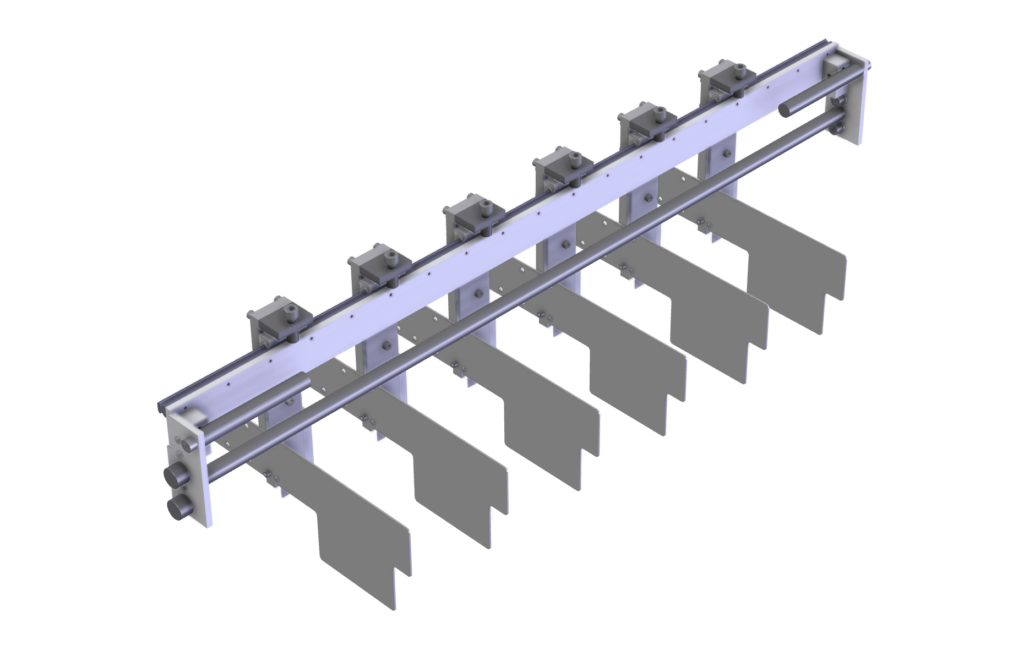

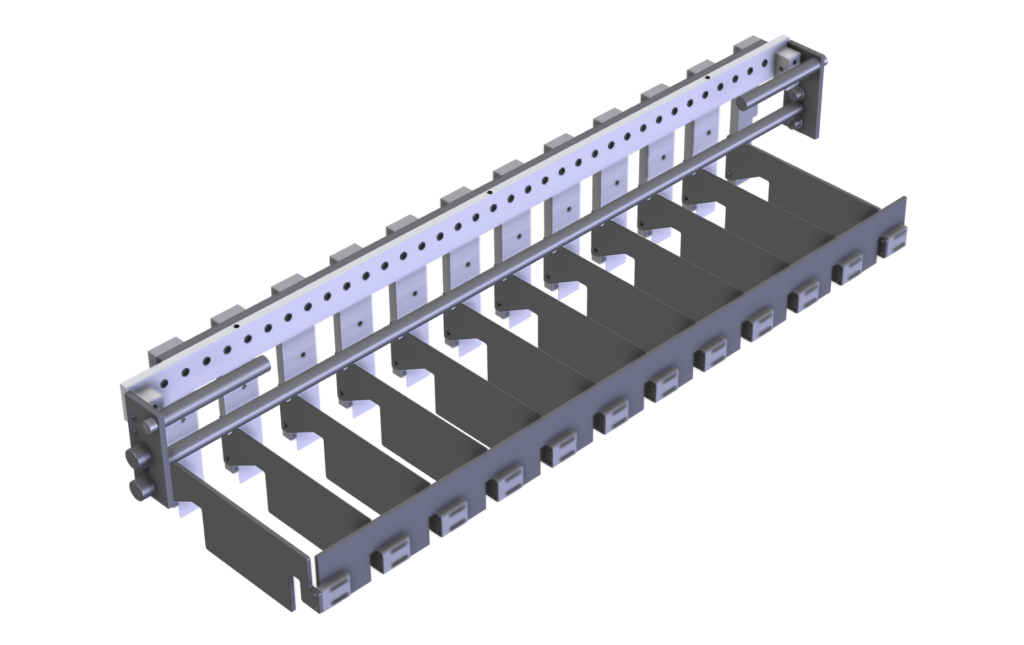

Blank Buffer

The blank buffer is made with highest quality components to grant a smooth transfer of blanks and blank stacks into the compartments. Blank collectors for different blank sizes and even in customized executions are available.

Accessories Welder

Welding roller dressing unit

Professional and exact profiling of the welding roll is an important factor for a smooth canbody production. With Soudronic’s dressing unit this job can be done on a high-quality standard, no matter which brand of welding roll is used.

Cold pressure welder

With the cold pressure welder two ends of copper wire can be welded together if the copper wire coil is empty or after a wire break. Welding the two ends together avoids the job of re-threading the copper wire which can be a quite time-consuming job, especially on aged welders and welders of other brands because the wiring is complicated.

Tinplate hardness tester BLTE 1000

Easy but efficient: With the spring back tester material hardnesses can be tested very easily. Such a check can be made when sheets are entering the plant to make sure that the material is supplied as ordered as well as on the slitter. Material-differences in regards of hardness and temper which might result in waste or down time cost much more money than a control device.

Ball tester

Check the stability/strength of the seam throughout the entire canbody length, including beginning and end of the welded seam. The seam has to withstand either high pressures and mechanical stresses, especially aerosol and food cans.

Inside diameter measuring unit

With the easy to handle and compact inside diameter measuring unit offline quality controls can be done very easily and the set-up process in case of a format-change can be monitored and controlled.

Body Blank Measuring BBM 1250

A good can starts with a good blank. To do important offline controls we provide the Body Blank Measuring BBM 1250 unit to ensure that cutting tolerances are kept within the limits.

Accessories Coating

MICRO.MATE

The coating thickness meter MICRO.MATE is very easy to use and is ideal for iron and steel substrates from 0 to 1000 µm. It measures layers of coating materials according to ISO 2178 and works from a 2 mm diameter spot size. The compact, lightweight device is barely larger than a measuring probe and is ideal for on-site applications in areas that are difficult to access.

CURE.LOG

Thermal management in an oven is crucial to ensure good quality of a weld seam protection cover. Soudronic has developed CURE.LOG, a top-notch data logger that tracks the accurate temperature, torsion and shock of the can. This smart recorder, that fits in your pocket, collects curing profiles quickly for process monitoring, optimization, or troubleshooting.

Stripe Cutter STC

The STC stripe cutter cuts stripes out of welded and coated can bodies for quality control purposes.

Format range:

- Diameter: 45 – 185 mm, stripe width: 23 mm

- Diameter: 52 – 185 mm, stripe width: 23 mm

- Diameter: 99 – 330 mm, stripe width: 33 mm

- Height: 320 mm

- Sheet thickness max.: 0,32 mm

Accessories Curing

CURE.LOG

Thermal management in an oven is crucial to ensure good quality of a weld seam protection cover. Soudronic has developed CURE.LOG, a top-notch data logger that tracks the accurate temperature, torsion and shock of the can. This smart recorder, that fits in your pocket, collects curing profiles quickly for process monitoring, optimization, or troubleshooting.

MICRO.MATE

The coating thickness meter MICRO.MATE is very easy to use and is ideal for iron and steel substrates from 0 to 1000 µm. It measures layers of coating materials according to ISO 2178 and works from a 2 mm diameter spot size. The compact, lightweight device is barely larger than a measuring probe and is ideal for on-site applications in areas that are difficult to access.

Stripe Cutter STC

The STC stripe cutter cuts stripes out of welded and coated can bodies for quality control purposes.

Format range:

- Diameter: 45 – 185 mm, stripe width: 23 mm

- Diameter: 52 – 185 mm, stripe width: 23 mm

- Diameter: 99 – 330 mm, stripe width: 33 mm

- Height: 320 mm

- Sheet thickness max.: 0,32 mm

Accessories Can Assembling

Spindle sleeve pressure tester

Correct and uniform setting of all seaming tools ensure high seam quality. Simple monitoring and setting reduce the time for pressure setting significantly.

Accessories Tester

Accessories 2-Piece Cans

Accessories End Making

Tool changing carriage

Using a special tooling carriage allows tooling changeover to be done by one operator in a very short time.

Accessories Peel-off

Offline pressure tester

The offline pressure tester allows a continuous monitoring of the peel-off end performance.

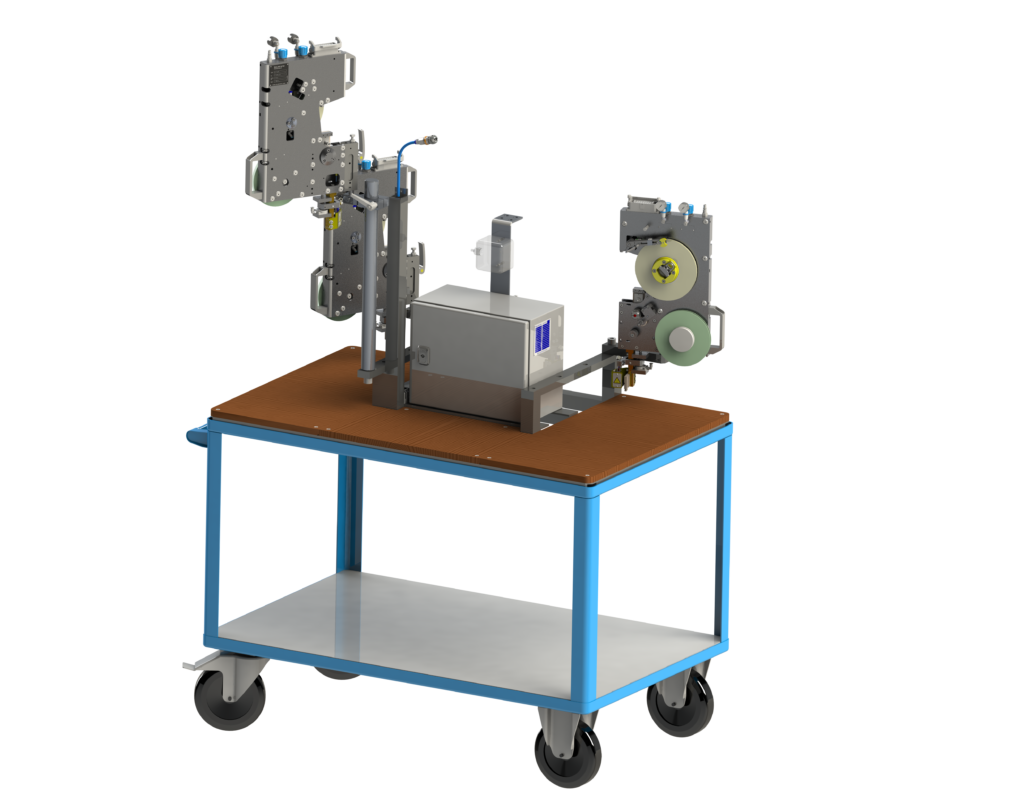

TFU offline station

The offline station allows an easy tape replacement, maintenance, cleaning and function tests. This reduces the machine down time.

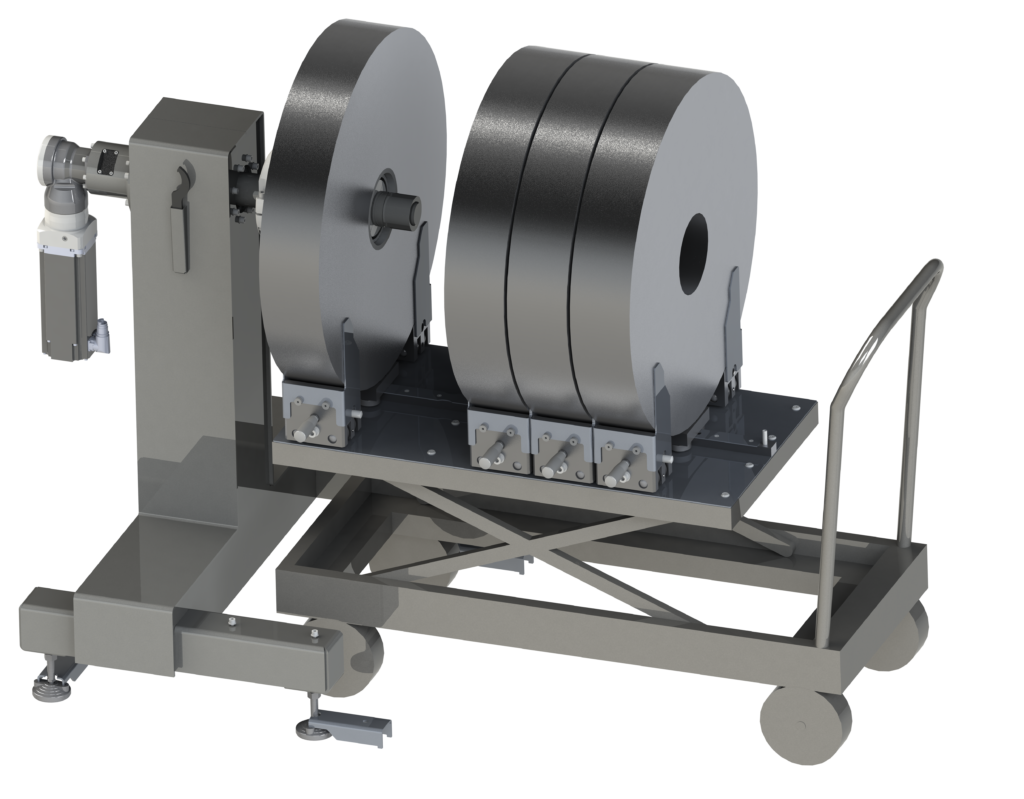

Loading device for membrane coil

Several coils can be stored on the loading device at the same time. This allows for a quicker coil change as the loading device stays in place.

Coil handling

The membrane coil lifting device facilitates coil replacement.

Accessories Conveyor

Accessories Palletizer