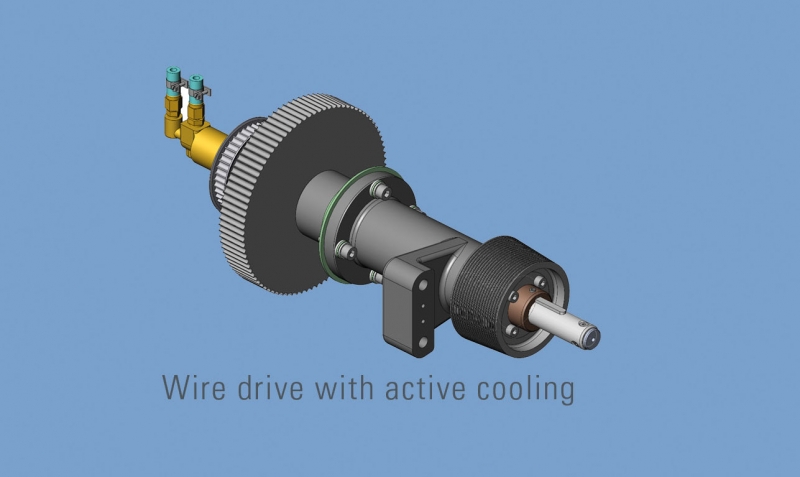

Active cooling for SOUCAN 800-2000 wire drive roller

High welding speeds call for special measures to prevent tin build-up in the wire guide pulleys.

With conventional wire systems (excluding UNIWIRE technology), the copper wire is no longer actively cooled once it has passed through the lower welding roller. Combined with high welding speeds, the lack of cooling leads to an increase in the temperature of the wire drive pulley and can cause tin deposits to build up in wire guide pulleys further down the line.The wire drive can be replaced by an alternative model with integrated, active cooling. Here, the cooling medium flows through the drive shaft and cools the wire drive pulley via a cooling flange.