IPA members impressed by live demonstration at Frei AG

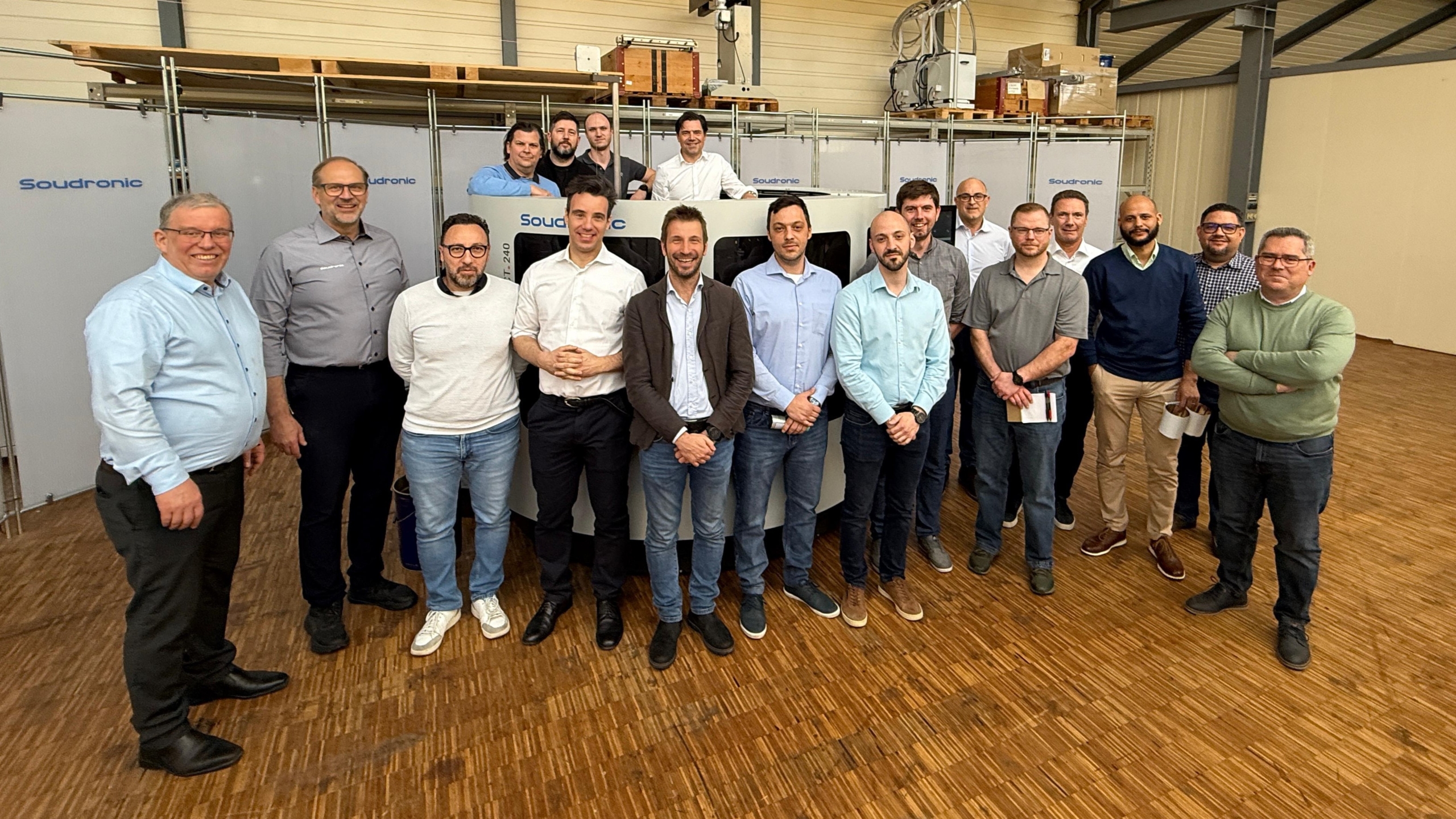

On April 2, 2025, around twenty members of the International Packaging Association (IPA) gathered at Frei AG in Wittenbach for a highly anticipated plant visit, highlighted by the exclusive live presentation of Soudronic’s latest innovation—the COMPACT 240 welding machine.

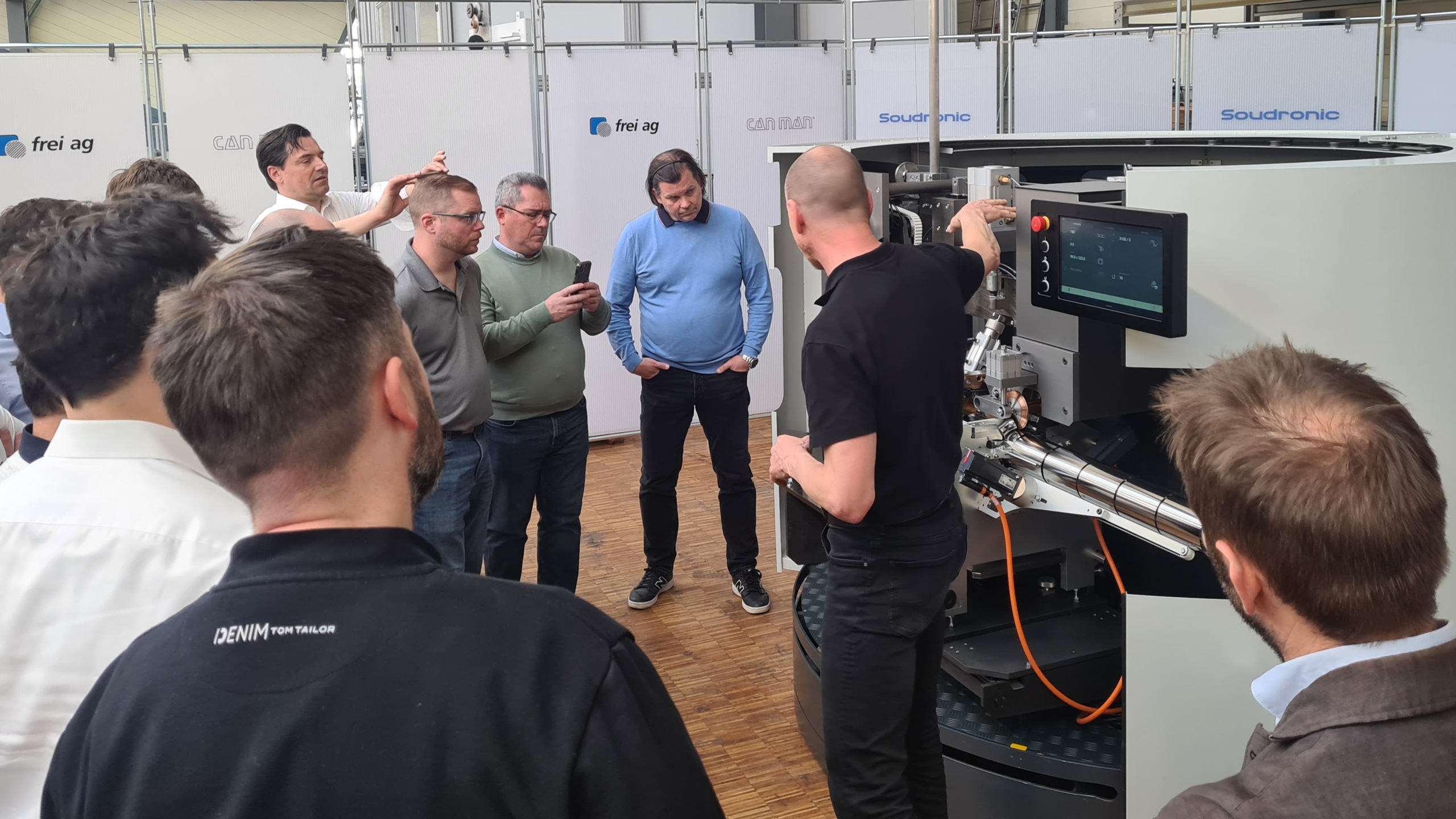

The plant visit marked the start of this year’s general meeting of the IPA Technical Committee and was dedicated to exploring cutting-edge developments in can-making technology. Rolf Geide, CEO of the Soudronic Group, welcomed delegates representing leading international can manufacturers to Frei AG. The renowned specialist in coating and curing systems proudly hosted the event and showcased its technological capabilities, including a demonstration of outside powder coating on the test system.

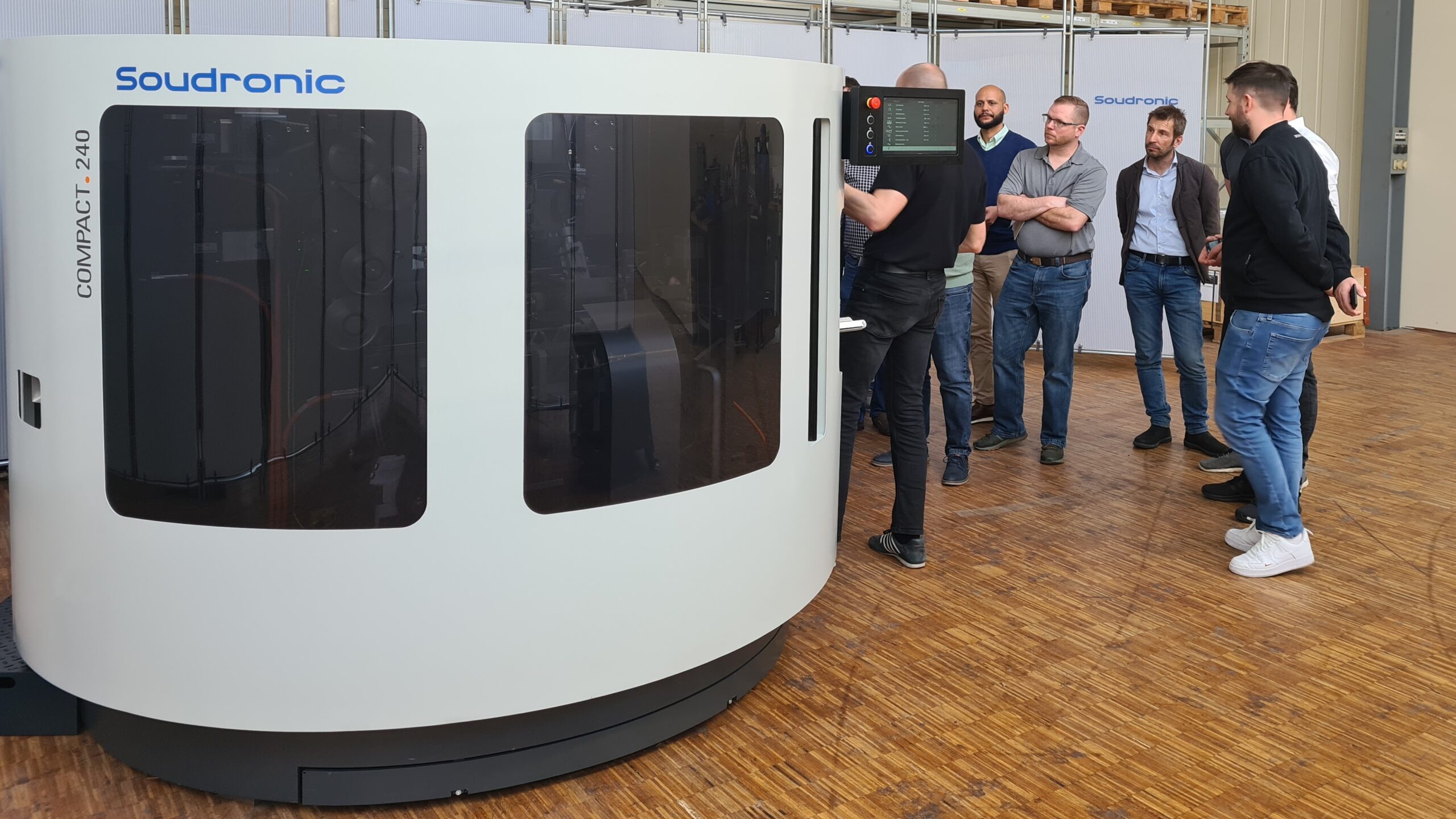

Exclusive presentation

However, the standout moment was undoubtedly the first-ever live presentation of the COMPACT 240 welder—a major technological leap for the industry. The machine was transported and set up at Frei AG specifically for this event, underscoring the remarkable compactness and quick assembly, which enables installation in just one day. The audience of technical and operations professionals was particularly impressed by the machine’s performance. In addition to its speed and compact cylindrical shape, the COMPACT features a top or bottom seaming concept which is unique to find in one basic machine design!

New developments

Following the plant visit, IPA members convened in Konstanz for a two-day meeting of the Technical Committee. Ruedi Umbricht, COO of the Soudronic Group, participated as a guest speaker and provided further insights into the Group’s latest developments.

One focus of the presentation was PowerCOAT oP, a new solution for outside powder coating. The new powder type is highly opaque and allows customers to choose the color that perfectly matches the canbody decoration.

For can makers aiming to reduce costs in seam coating, a practical solution was introduced. For those using the same powder for inside and outside coating Frei AG offers a main powder tower that supports both applications, resulting in simplified processes, minimized material usage and reduced investment.

Umbricht also drew attention to Soudronic’s replacement strategy: Many machines have been in operation for decades and are becoming increasingly difficult to service. The lack of personnel with the necessary knowledge of these machines and the increasing difficulty in procuring hardware for the old control systems is not only a challenge for Soudronic, but an industry-wide problem.

The presentation concluded with a spotlight on mySoudronic, the new customer portal from Soudronic. The online demonstration showcased the platform’s wide range of features, including Academy e-learning modules, self-service tools, service ticketing, and access to machine documentation. In addition, the portal offers a real-time overview of production performance through intuitive, easy-to-read dashboards. These tools are designed to provide comprehensive support to Soudronic customers and operators anytime, anywhere, and on any device.

Jörg Pfützner, metal packaging engineer and head of IPA’s Executive Office, summarized the experience:

«We truly appreciated the opportunity to visit Frei AG with our members and were deeply impressed by the innovative solutions presented by Soudronic and Frei AG. Special thanks to everyone involved for their efforts and hospitality.»

About International Packaging Association (IPA)

Founded in 1953, the International Packaging Association (IPA) comprises over ten member companies spanning almost all continents. Its founding principles continue to guide its mission in the 21st century: to foster a global exchange of ideas, as well as technical and environmental expertise in an atmosphere of mutual trust. IPA empowers small and mid-sized independent metal can makers with the tools and insights needed to thrive in the modern world.