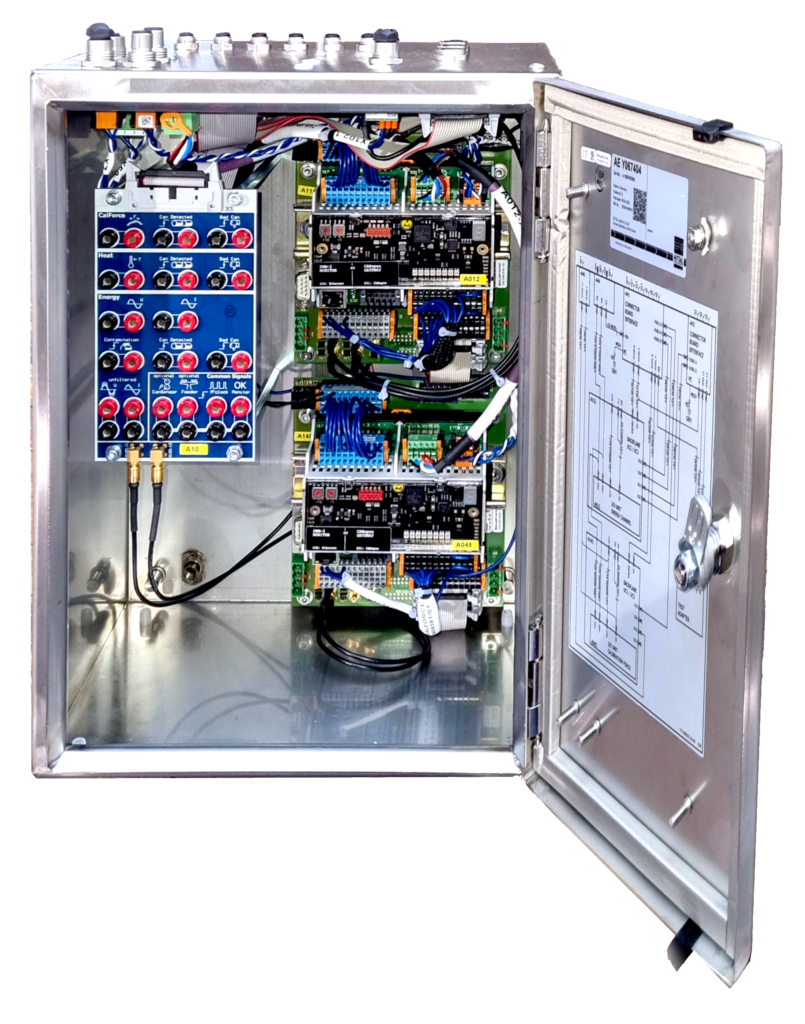

SWM-3 Monitor System

The SWM-3 Monitor System is the quality backbone of your welding machine for monitoring the weld seam and incoming sheets. It is seamlessly integrated into the UNICONTROL control system or available as a standalone version.

The modular system can be equipped with several monitoring channels as required, which can also be easily upgraded later. By combining the different channels, practically the entire spectrum of possible faults in can production can be reliably monitored. With the SWM-3 Monitor System, you can be sure that the monitoring of the quality of your cans is always state-of-the-art. Operators can rely on the reliability and simplicity of the monitor allowing them to focus on what is important – the production of your cans.

Equipped with the latest sensor technology and electronics, the system is ideally equipped for future tasks. Additional functions and algorithms can easily be added to keep it at the cutting edge of technology in the future.

Despite the modern technology, special attention has been paid to simple and understandable operation so that the system does not overwhelm the user, but supports him in his daily tasks.

Modular channel Concept

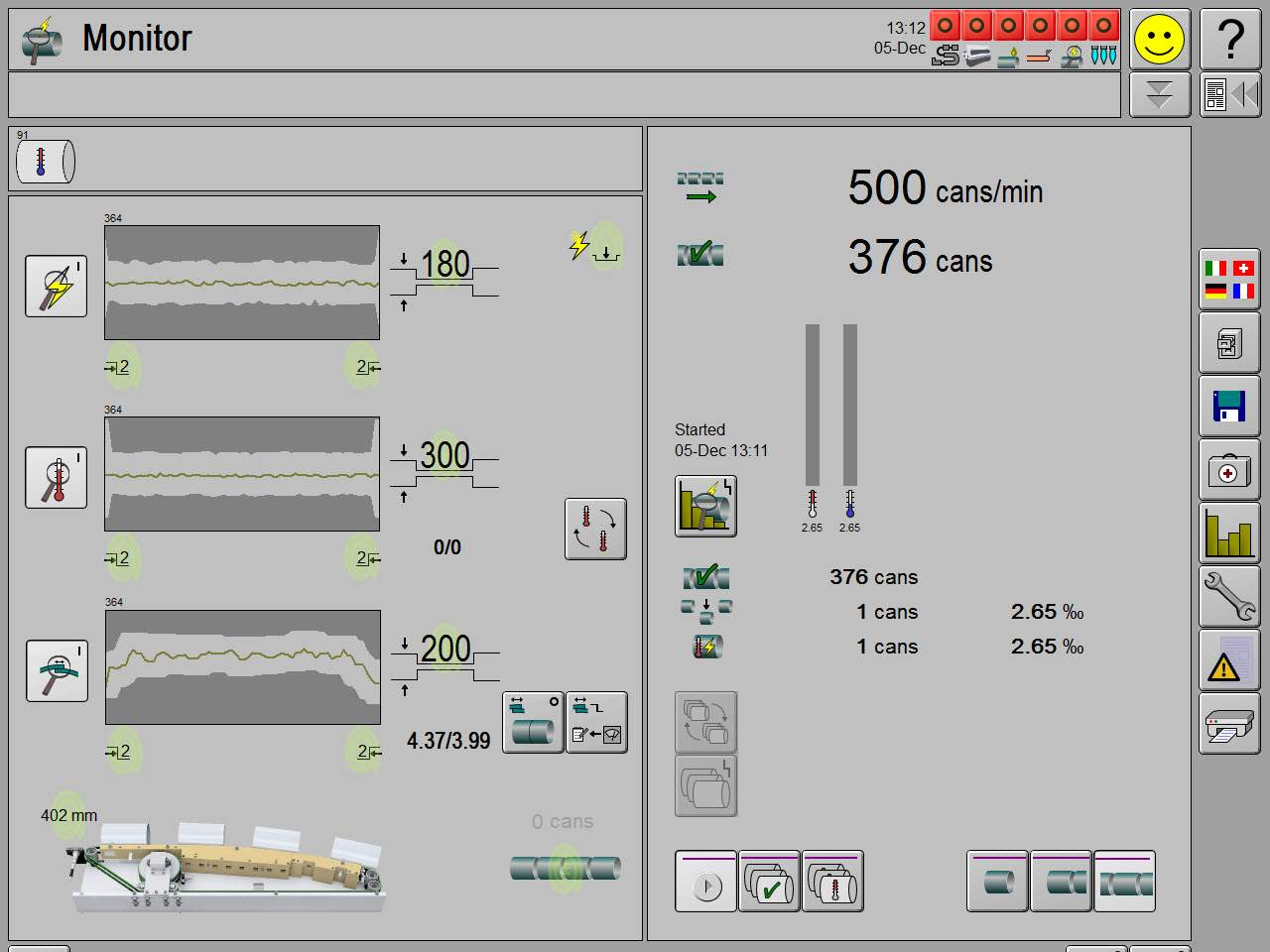

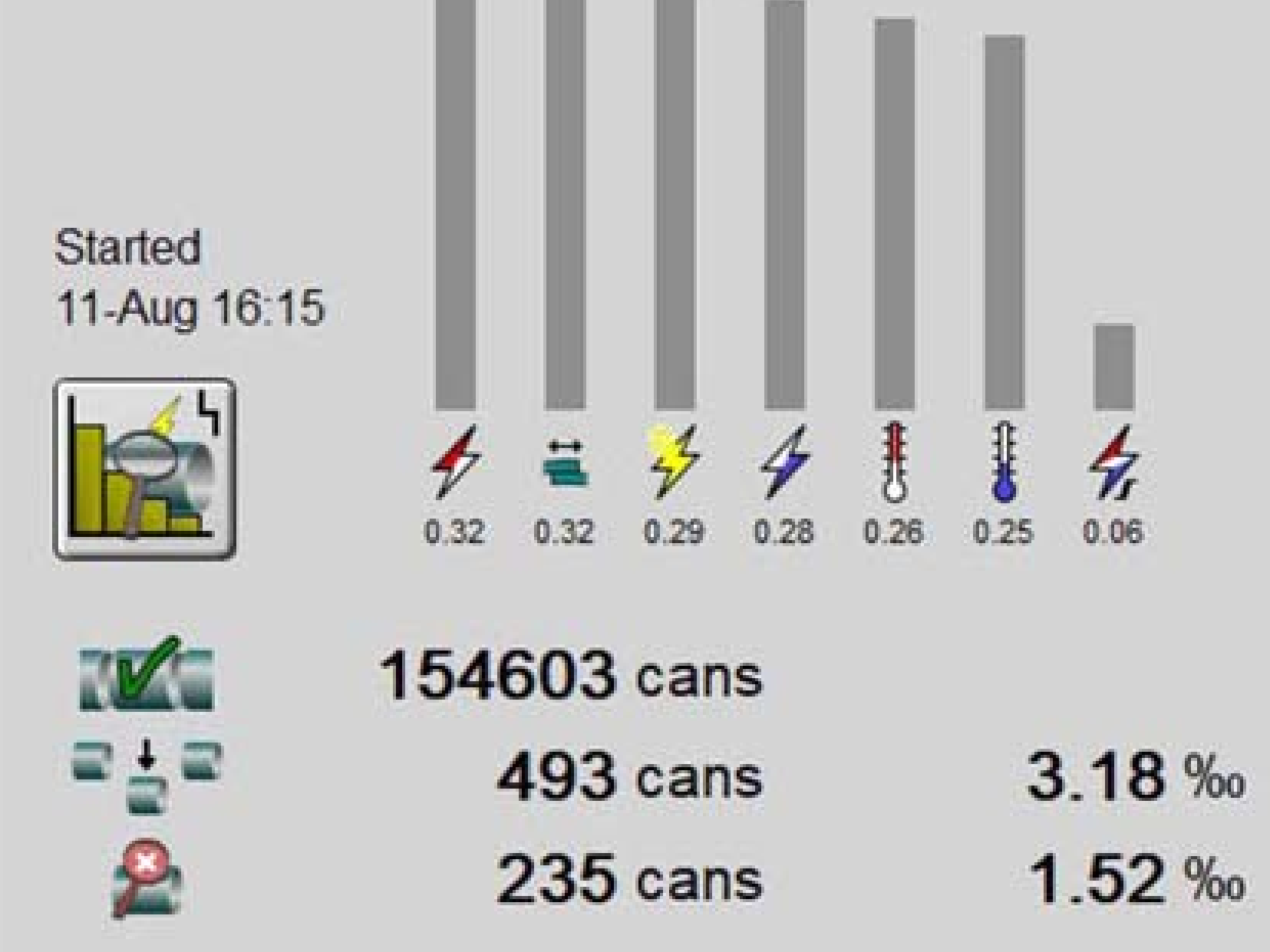

Each channel monitors its own quality parameters independently of the others. This allows the system to be flexibly expanded or combined with additional channels to improve the detection capabilities. Finally, there is a comprehensive evaluation and display of all measurement results, giving the user a quick and complete overview. Each channel can be individually adjusted with a few easy to understand settings.

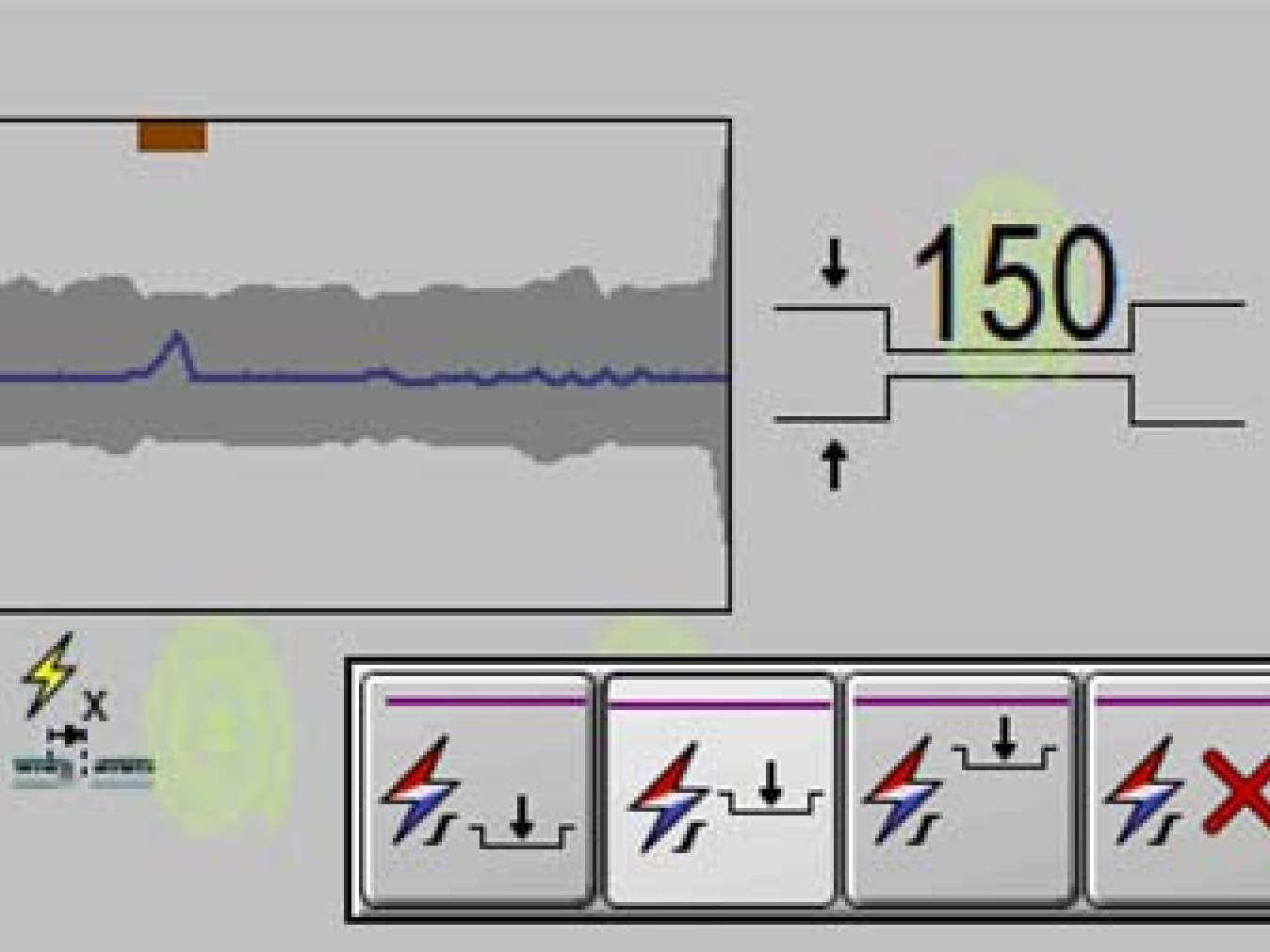

Energy channel

The energy channel measures the welding current and voltage to calculate the energy on each welding spot.

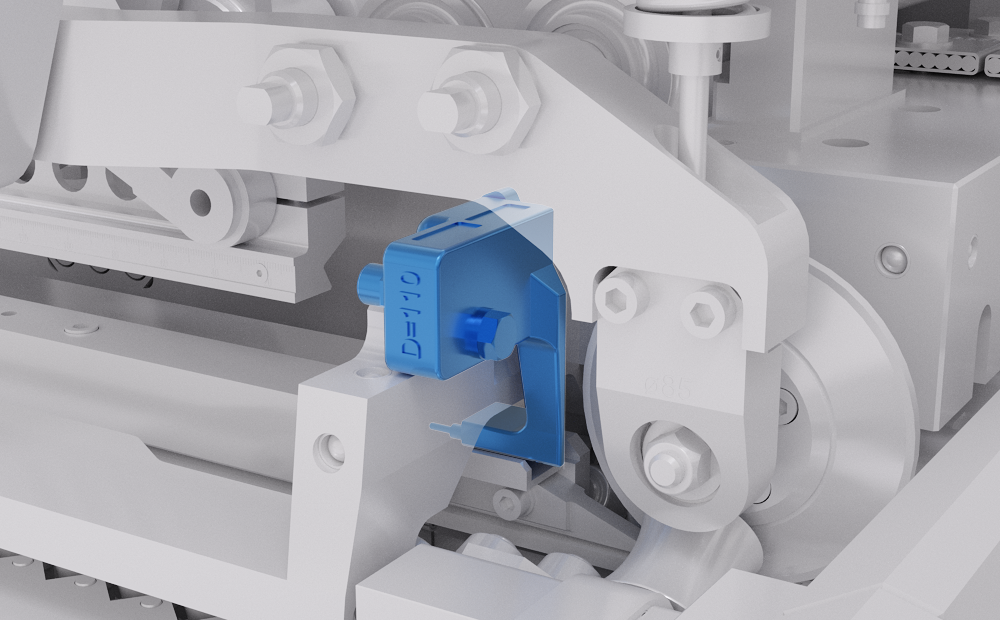

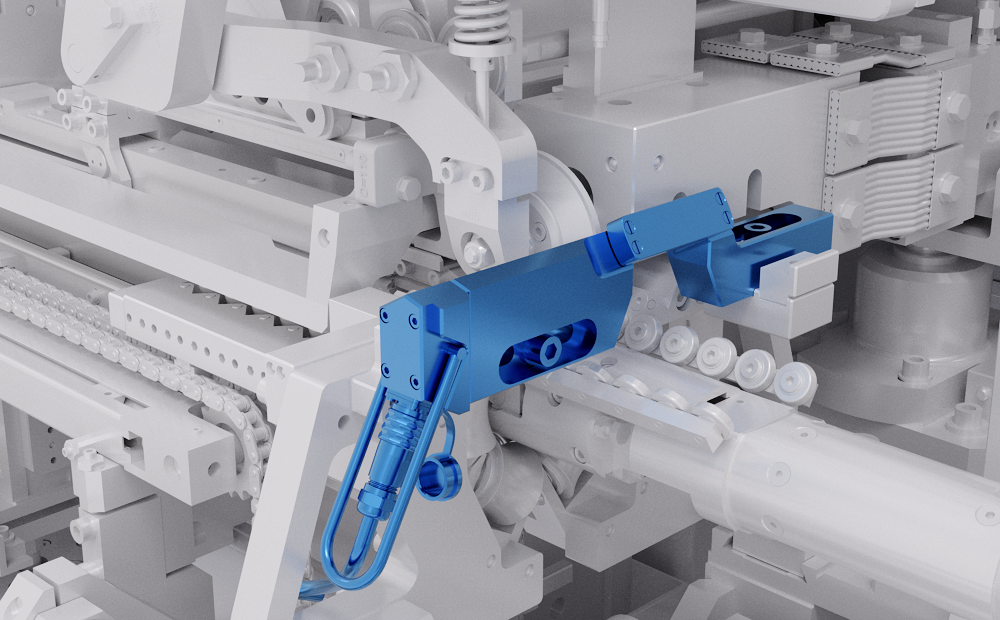

Calibration Force Monitor channel

The Calibration Force Monitor channel captures the needed force to calibrate the sheets to the desired diameter.

Heat channel

The Heat channel converts the heat radiated from the hot welding seam into a monitor signal.

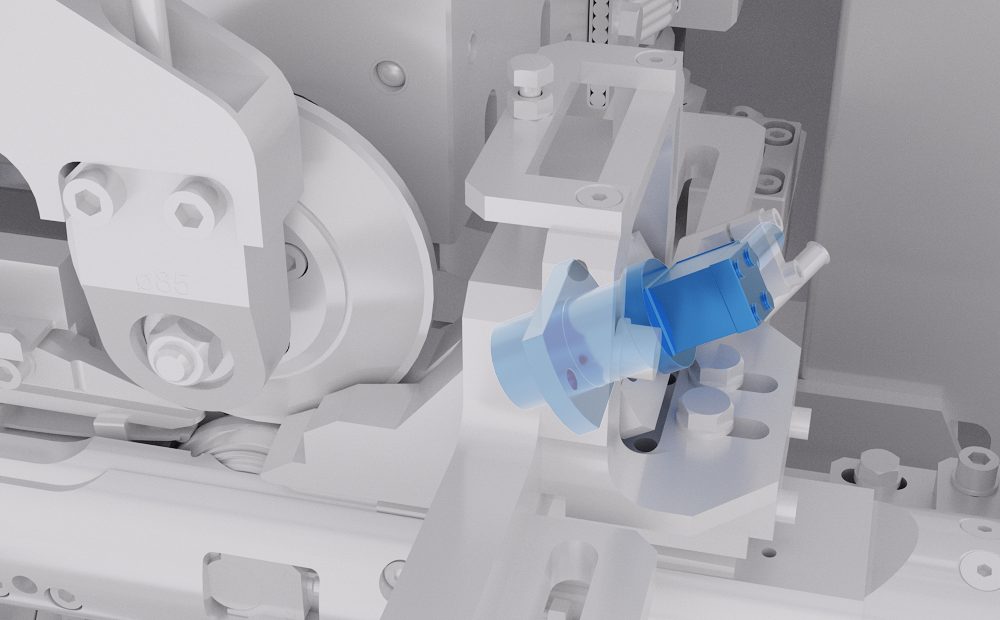

Pulsar OCR-R

The aim of the OCR-R system is to prevent wire breakage and to protect the roller heads from sporadic contaminations.

Advantages and benefits:

- Highest reliability

- Effective quality supervision of weld seam

- Online monitoring

- Fast return on investment due to time, material and money saving

- Meeting highest quality demands

- Minimal risk of wire breaks and damage to welding rollers

- Can bodies with cold welds caused by overlap errors are detected and ejected (with CFM)

- The monitor signal lets users know that welding is set correctly (with CFM)

- Less down-time

- Increase of production efficiency

- Fewer reject cans in the downline

Working principle

Through a common setup of a few welded cans, the system is taught where the tolerance band is for a single can. In case of fluctuations of the welding parameters, this can also be repeated during production, whereby the setup cans are ejected for the user to check. The cans that do not pass the evaluation will be ejected from the ejection station and the display will show the reason for the rejection.

It is easy to check the function of the monitor: Real-time data of the last 12 cans are continuously stored and can be retrieved at any time. In addition, experienced operators can use the real-time data to get an immediate overview of the status or a variation of the current production.

Clear statistics help you to evaluate the short- and long-term performance of your system.

SWM-3 Specifications

| Type | SWM-3 | SWM-3 | SWM-3 | Pulsar |

| Energy channel | Calibration Force channel | Heat channel | Overcurrent Reduction | |

| ENERGY | CFM | HEAT | OCR-R | |

| Defect within seam area | > 1.5 mm | no | > 1.5 mm | no |

| Defect beginning/end (folded corners) | > 1.5 mm | no | > 1.5 mm | no |

| Body offset | > 1.5 mm | no | > 1.5 mm | no |

| Overlap (deviation) | – | +/- 0.1mm | > – 0.3 mm | no |

| Seam contamination (overlacquering) | > 1.0 mm | no | > 1.0 mm | > 1.5 mm |

| Min. weld speed without oxide-free seam | – | – | >= 20 m / min | – |

| Min. weld speed with oxide-free seam | – | – | >= 25 m / min | – |

| Wire protection | yes | no | no | yes |

| Ejects first and/or last can | yes | yes | yes | yes |

| Single can production monitor | yes | yes | yes | yes |

| Compare tool settings at production start | no | yes | no | No |

| Discover cutting variations | no | yes | no | no |

| Mask out can scoring / tactile | – | available | – | – |

| UNITOOL required | no | yes | no | no |

Contact form

Please contact us for a detailed quotation.