Maintenance-free chain

Various customers preferred belt transport in the past, because unlike chain transport, they did not require active lubrication.

A disadvantage of the belt transport was the incompatibility with a third feed system (under square can formats) and that not all pitches of the previous chain transport were available.

In the past, we were not able to meet food industry’s need for a lubricant-free conveyor chain. Conveyor products had an inadequate service life and were time-consuming for replacement because the drive axles had to be separated.

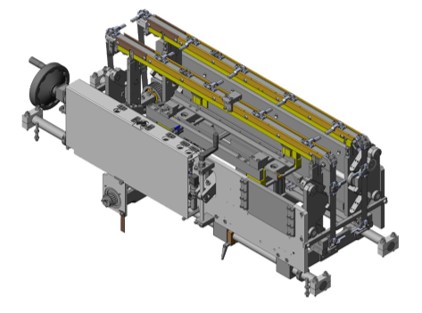

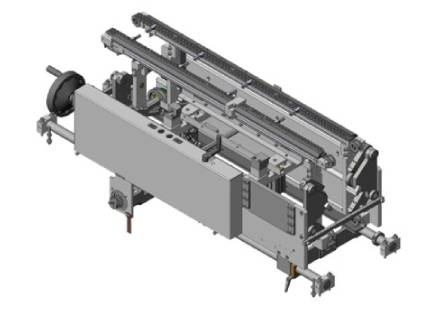

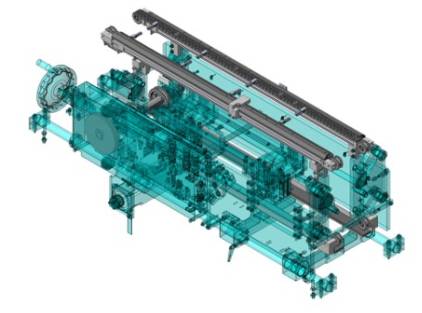

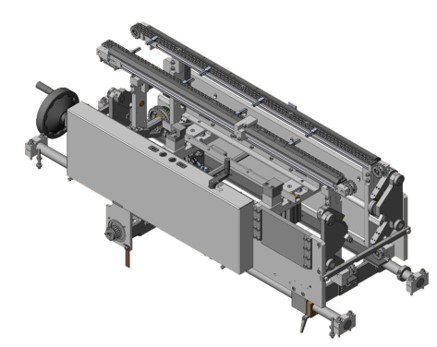

The new maintenance-free conveyor chain minimizes maintenance work. By modifying the T1 conveyor unit, the oil-lubricated conveyor chain can be replaced with the maintenance-free chain so that the oil lubrication system is no longer needed.

Advantages

- Lubrication no longer required

- A third feed system can be added

- All the pitches of the previous chain are available

- No non-ferrous metals in the chain guide (wear)

- The chain guide no longer needs to be cooled (leakage)

- Chain dogs made of CrNi steel (heating through electric field is extremely low)

- Attractive design

Retrofitting

Chain belt conveyors on older machine types can be retrofitted with the maintenance-free chain on request.