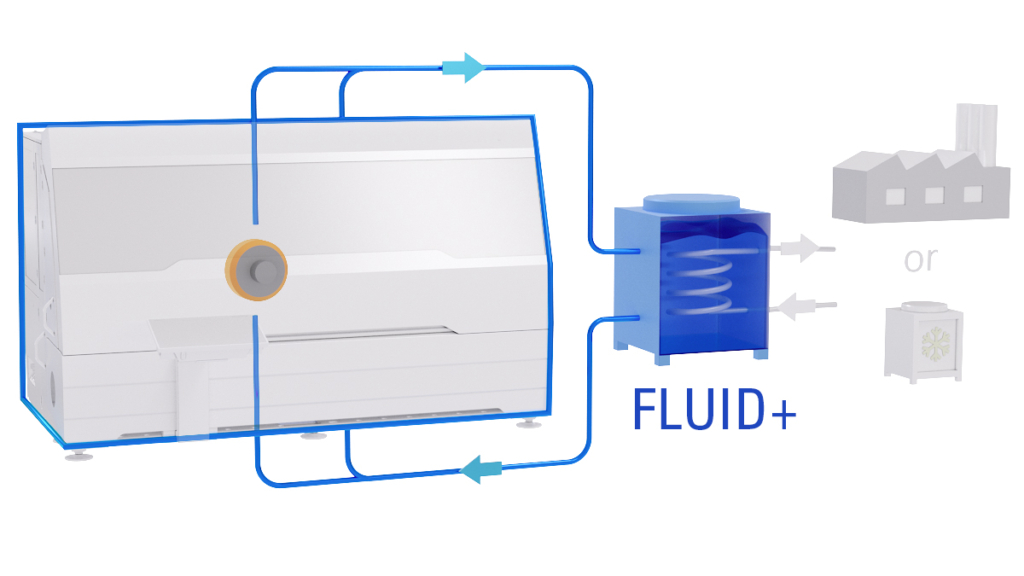

FLUID+ cooling system

Our enhanced FLUID+ cooling system integrates the cooling of both the welding machine and the DISCON+ roller head into a single closed circuit using a single medium, replacing the previously separate systems. This new concept combines the FLUID+ heat exchanger with the specialized FLUID+ cooling medium for optimal performance.

Engineered for long-term durability and efficiency, the FLUID+ cooling system is standard in all new Soudronic SOUCAN and COMPACT series, as well as Can Man X series welders, starting from the 2023 production year onward.

FLUID+ heat exchanger and FLUID+ coolant

The FLUID+ cooling system features a newly developed, temperature-controlled FLUID+ heat exchanger that delivers stable and efficient cooling across the entire welding machine, including the DISCON+ roller heads.

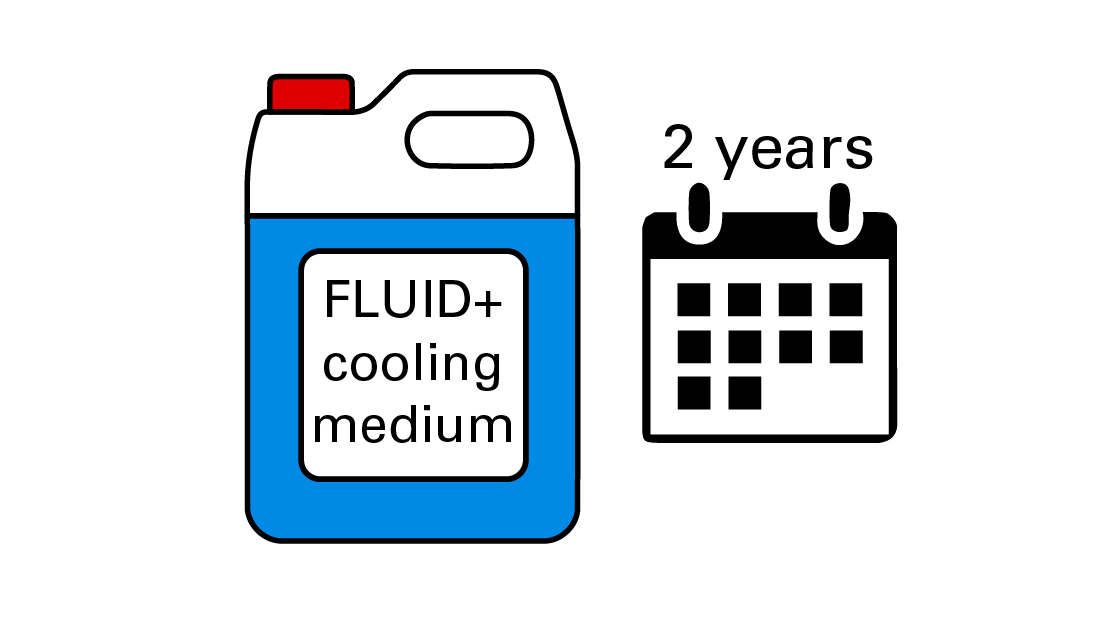

It uses the NSF-approved FLUID+ coolant, specifically formulated for use with the FLUID+ heat exchanger. Thanks to its long service life of up to two years, the coolant reduces maintenance requirements and greatly simplifies the cleaning of the cooling circuit. Furthermore, the cleaning is reduced to a minimum. The result is enhanced overall efficiency and reliability of the welder.

Features and Benefits FLUID+ cooling system

FLUID+ heat exchanger

- Cooling capacity 30 kW

- Filling volume 40 – 55 liters

- Max. distance to welder 20 m

(2 x 20 meters of hose included) - Power supplied by the welder

- Temperature controlled

- Closed system

- Dimensions LxWxH

78cm x 61cm x 92cm - Order no. 64-435607200

FLUID+ cooling medium

- Unprecedented durability and consistent performance for 2 years

- Reduces maintenance intervals and cleaning effort of the coolant system

- Concentrate of 25 – 35 vol.-% in demineralized water

- pH value 6.5 – 7.5

- Exclusively for FLUID+ cooling system

- Order No. 85-650020590

NSF approval

The new FLUID+ coolant with NSF approval is designed exclusively for the use with the FLUID+ heat exchanger unit.

- Food approval NSF 169561 U1