High efficiency end making systems for lids and shells

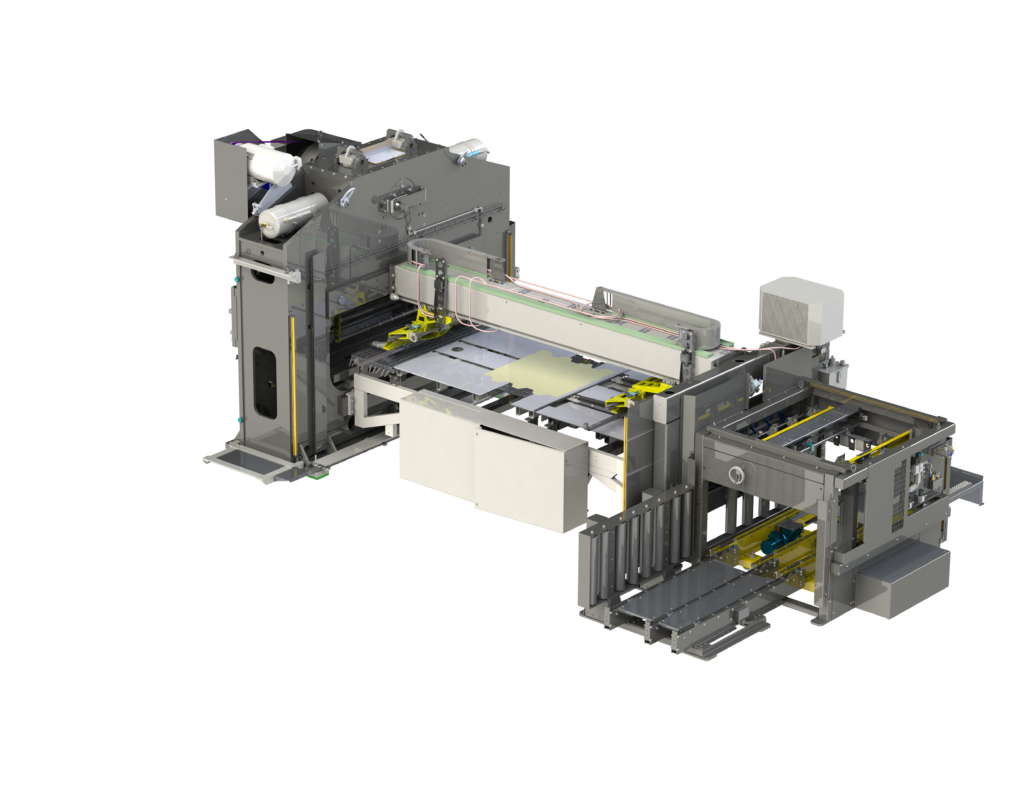

The END-O-MAT combined machine systems are designed for medium and high-speed end production for lids, EO shells, rings and bottom ends and meet all technical and commercial challenges of an end maker. The machines perform stamping, curling and lining operations and are available with sheet or coil feeding.

Our UNIPRESS machines are designed to produce deep-drawn cans as well as regular lids, end or shells. The machine can perform several stages like stamping, pre-drawing, final-drawing, embossing, paneling and trimming.

Filter Application

End Forming

Curling

Lining

Handle Welding

Shape

Round

Irregular Shape

Series

END-O-MAT

UNIPRESS

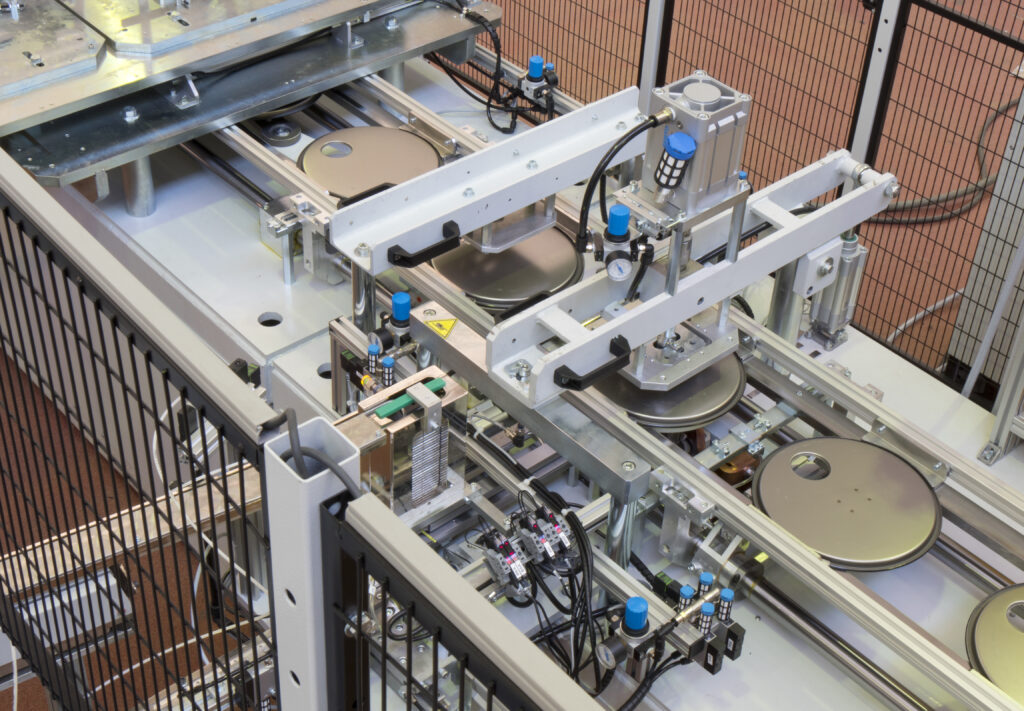

Disc Curler

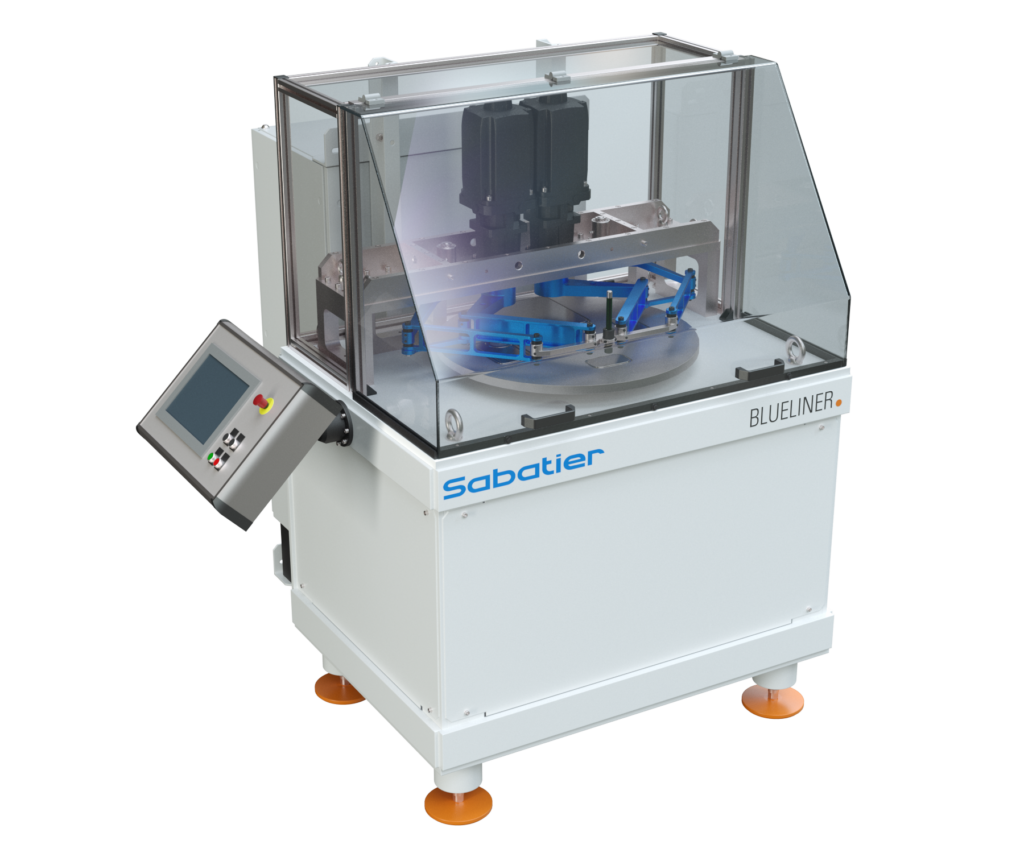

High-Speed Liner

Curler Liner Round

Curler Liner Irregular Shape

Clip Welder Round

Clip Welder Irregular Shape

Series

Application

Shape

Production [epm]

End Dimensions Ø [mm]

End Dimensions L x W [mm]

Max. press force [kN]

Number of Strokes [strokes/min.]

Ring / End material

Ring thickness

Lanes

Company Brand

UNIPRESS

End Forming

Round, Irregular Shape

Up to 1800

46 – 225

60×40 – 235×235

800

80 – 225

Steel or aluminium

Fe 0.14 – 0.35AI 0.15 – 0.35

1 – 8