UNICONTROL

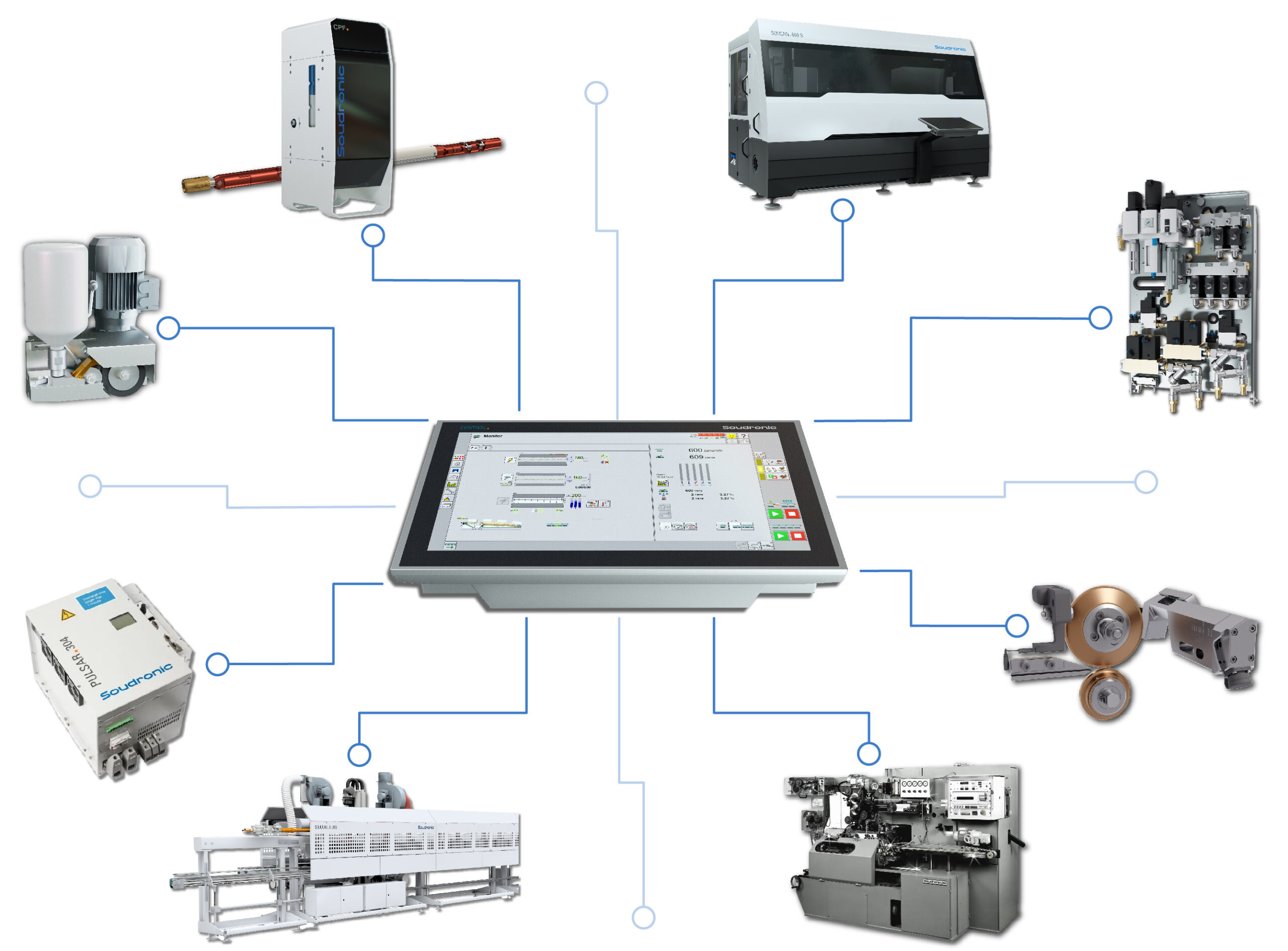

UNICONTROL is the future-proof control solution. It combines user-friendliness, quality assurance, and Industry 4.0 capabilities in one powerful system. Customers benefit ever since from all advantages of UNICONTROL and can count on the availability for decades to come. Our control system offers great modularity and connectivity for machines and monitoring systems by simply plug & work.

Features and Benefits UNICONTROL

Keeping up with technology

You will always get the latest UNICONTROL generation suitable for your system.

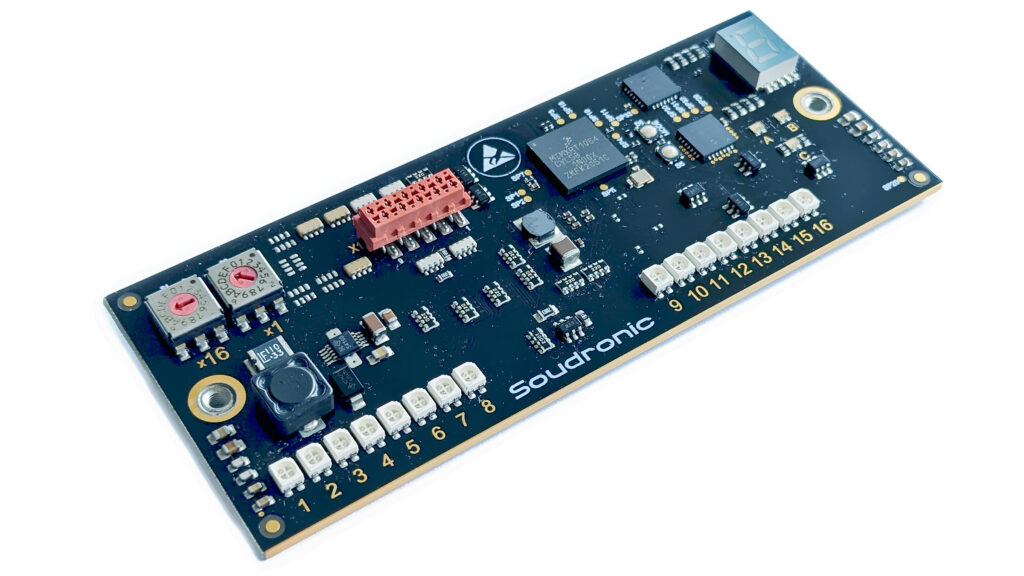

Circuit boards are developed, manufactured and tested in Soudronic’s headquarters in Switzerland.

Backward compatibility

Further development guaranteed for the coming decades.

- Consistent support for the control system

- Keeping up with technological advancements and industry needs

- Spare parts availability is guaranteed due to safety stock

UNICONTROL SA (stand-alone)

The new UNICONTROL SA stand-alone solution can be integrated into your line wherever needed when you are adding a new monitoring system or replacing your seam protection or curing system. UNICONTROL SA replaces all previous stand-alone systems.

- One control panel for all connected systems

- Large 24″ touch screen monitor

- Control cabinet is height-adjustable

Soudronic Insights Ready

Basic dashboard with time-limited live production statistics at machine and component level:

- Machine status

- Efficiency

- Top 5 errors statistics

- Production counter

- Event log

UNICONTROL – Smart welding control

Discover how UNICONTROL by Soudronic revolutionizes high-performance welding systems.

This video showcases the intuitive user interface, integrated process control, and real-time diagnostics that make UNICONTROL the ideal solution for modern, data-driven manufacturing. Experience the benefits of Industry 4.0 readiness, AI-supported optimization, and effortless format changes, all in one powerful platform.

Technology highlights and system overview

Innovation for modern requirements

- Fully integrated control for welding machine, seam coating, oven, and quality monitoring

- Format changes with real-time calculation of all process parameters

- OPC-UA interface for transparent data provision

- AI-supported analysis and optimization via Soudronic INSIGHTS

- Software updates and interchangeable hardware generations without programming

Focus on user-friendliness

- Intuitive touchscreen interface with optimized contrast

- Consistent operating concept across all UNICONTROL generations

- Clear-text error messages with step-by-step guidance

- Direct access to manuals, schematics, and system layouts

- Live production statistics and automatic event logging

Integrated quality assurance

- Role-based user management

- Real-time process monitoring with automatic error detection

- Recipe management with mandatory options to prevent errors

- Historical data tracking and external analysis via OPC-UA

- Data-driven optimization with Soudronic INSIGHTS

Advantages over conventional control systems

- Over 70 years of experience in welding technology and control systems

- No dependency on external programmers

- Centralized control of all processes via a single HMI

- Long-term availability of spare parts and support

- Performance reserves for future features like machine learning

User management available

Operators:

- Multilingual interface (28 languages)

- Configurable units (°C/°F, metric/imperial)

- Online help and integrated documentation

Maintenance:

- Clear-text diagnostics and maintenance scheduling

- I/O checks and bus diagnostics

- Software updates without external assistance

Management:

- Future-proof platform with ERP integration

- Access to production data for strategic optimization

- Easy integration of all Soudronic products

History of UNICONTROL

How it began

Back in the early 1990s, Soudronic began developing its AFB/FBB welder series. Designed to weld an unprecedented 1000 can bodies per minute, the machines placed enormous demands on control system response times and processing speed and outstripped the capabilities of all commercial systems available at the time. Seeing no alternative, Soudronic decided to create a solution of its own that would not only take the necessary speed in its stride but also reduce the wiring outlay and the variety of PCB hardware.

Key features at the time

- Reduced PCB hardware from over 20 per machine to just five.

- Increased welding rate to 1100 can bodies per minute.

- Distributed configuration with I/O boxes communicating via CAN bus, reducing wiring needs.

- Integrated welding monitor for all cycle rates.

- Transition from static welding converter UNISOUD to PULSAR.

First redesign in 2000

- Focus on backward compatibility and affordability.

- Introduction of Windows XP and SMD technology in electronics boards.

Ongoing evolution from 2010

- Introduction of UNICONTROL 3, with internet capability and reduced hardware size.

- Decreased the number of electronics board variants to three, enhancing production and testing processes.

Continuous development from 2020 onwards

- Introduction of the new UNICONTROL 4 drive system and its associated safety concept.

- Achieving performance enhancement by changing the processor platform.

- Backward compatibility with previous generations of UNICONTROL is guaranteed.

Future outlook

- Continued emphasis on interoperability with legacy systems.

- Commitment to state-of-the-art systems with comprehensive servicing and support.

- Implementation of future features such as machine learning

Evolution UNICONTROL panels