CURE.LOG

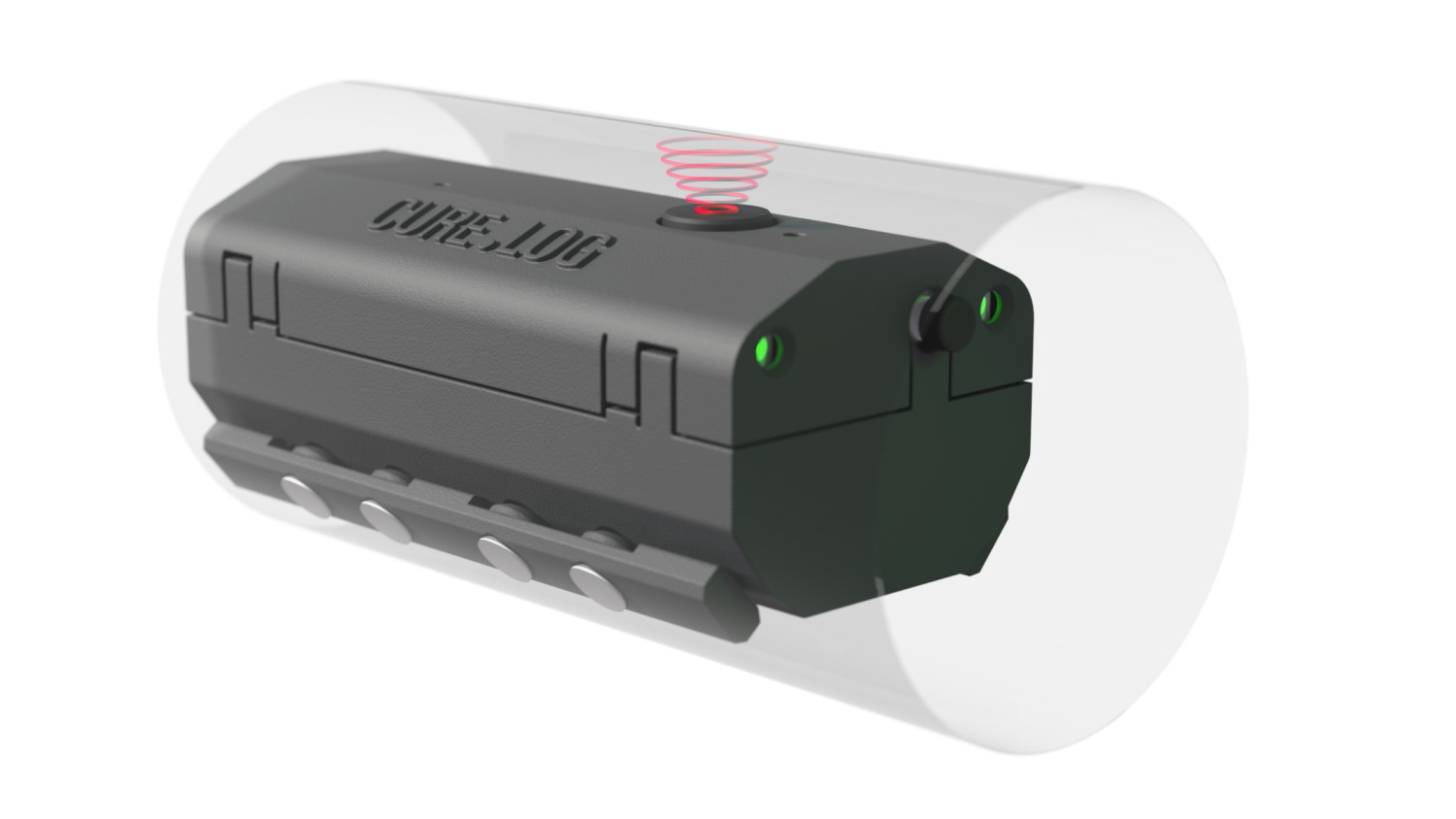

Thermal management in an oven is crucial to ensure good quality of a weld seam protection cover. Soudronic has developed CURE.LOG, a top-notch data logger that tracks the accurate temperature, torsion and shock of the can. This smart recorder, that fits in your pocket, collects curing profiles quickly for process monitoring, optimization, or troubleshooting. The optical and hence contactless measuring principle offers major advantages over classic probe measurement.

Features and Benefits CURE.LOG

Optical measuring principle

The optical measuring principle offers major advantages over classic probe measurement: The temperature is recorded contactless using an infrared sensor. CURE.LOG provides more reliable surface temperature data compared to the unreliable and tricky to handle contact measurement. With the built in acceleration sensor, twisting and vertical jolts can also be detected.

Can diameters from 45 to 210 mm

Magnets on the logger are used for its quick and easy fixation in the can. A light beam helps to align the logger’s sensor perfectly on the weld seam. The integrated led-based spirit level ensures perfect horizontal leveling of the can on the oven’s conveyor belt.

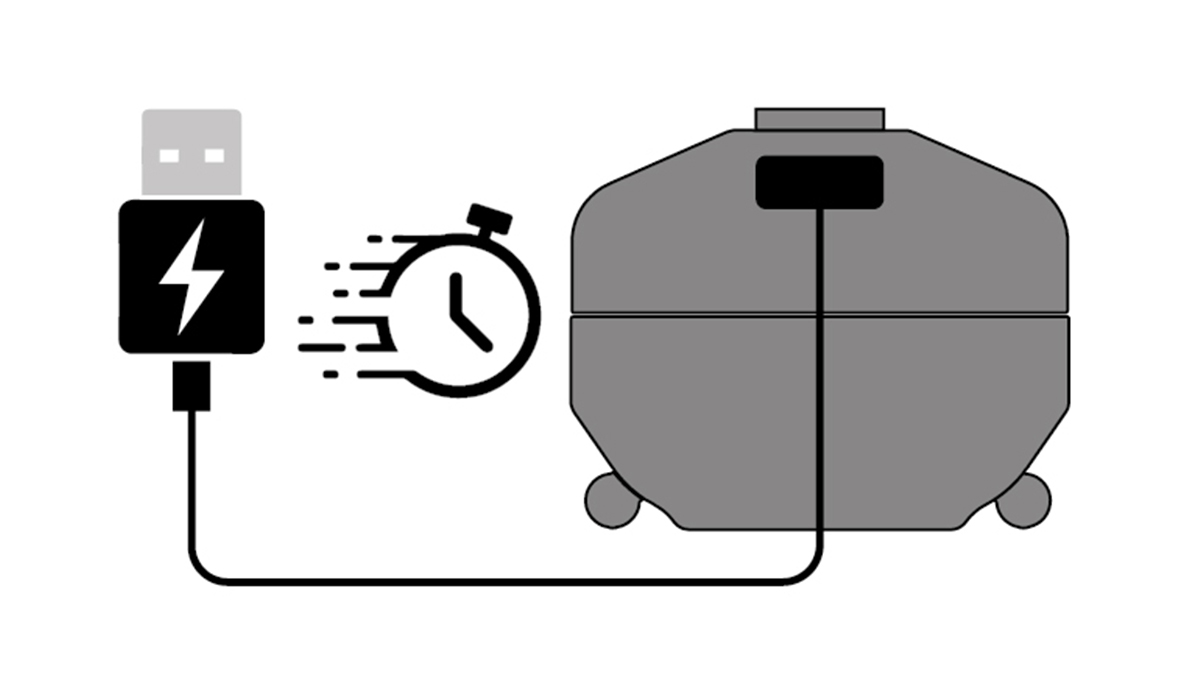

Fast charge, plug & play

The logger can be quick charged via USB-C port and you are ready within two minutes. While importing the data to your computer the logger gets recharged again. No batteries needed, no dangerous and aging LiPos!

Referenced emissivity

To ensure most accurate results, the high temperature adhesive tape with referenced emissivity needs to be applied to the can.

Data analysis

No software installation needed, simply analyze the logged data on your computer by using the Excel template provided on the logger.

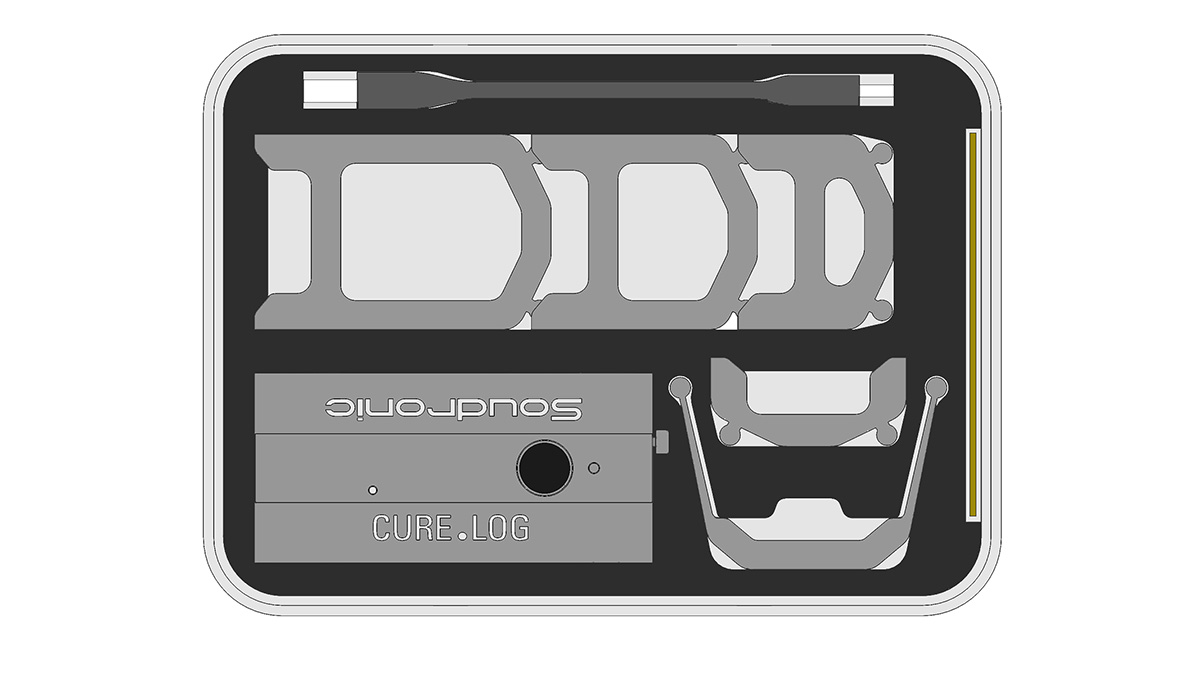

Compact case

Everything you need for accurate measurements in your oven is conveniently stored in one compact metal case. Including various spacers to attach the device to the different can diameters. Ready, steady, go!

Free e-Learning

Get started with the free CURE.LOG training session provided by mySoudronic’s academy.

Always up-to-date

Access the latest manuals and perform hassle-free firmware updates to benefit from the latest features. Easily done by yourself.

Calibration service

To ensure that measured results are always accurate, we offer a chargeable calibration service for CURE.LOG. This also helps companies that are ISO-certified, for example, to meet the regulation of periodic calibration of measuring devices.

Get a quote for CURE.LOG

Specification

| Can diameter | 45 – 210 mm |

| Measuring scope on can | 1 – 18 mm (depending on can diameter) |

| Max. welding speed | without turn: 150 m/min with turn: 70 m/min (magnetic support plate at turn required) |

| Measuring temperature range | 0 – 300°C |

| Operating temperature | 0 – 65° C |

| Dimensions | 81 x 40 x 33 mm |

| Charging time | < 2 min |

| Operating time, when fully charged | 5 measurements at 3 min |

| MS Excel | version 2021 or later required |