Coating and weld seam protection for quality cans

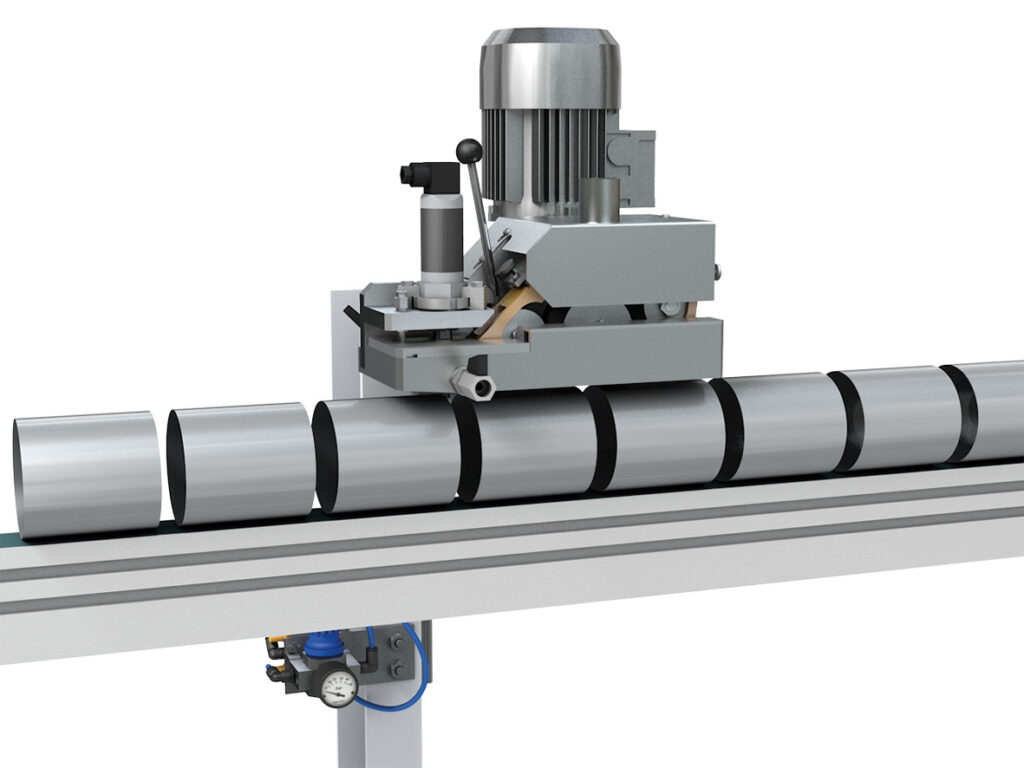

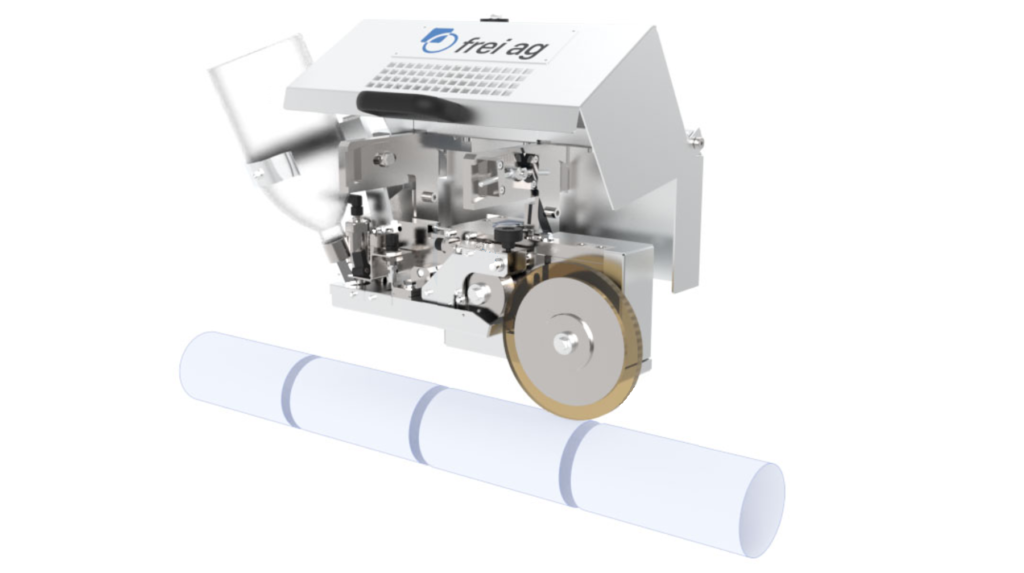

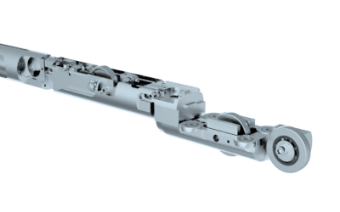

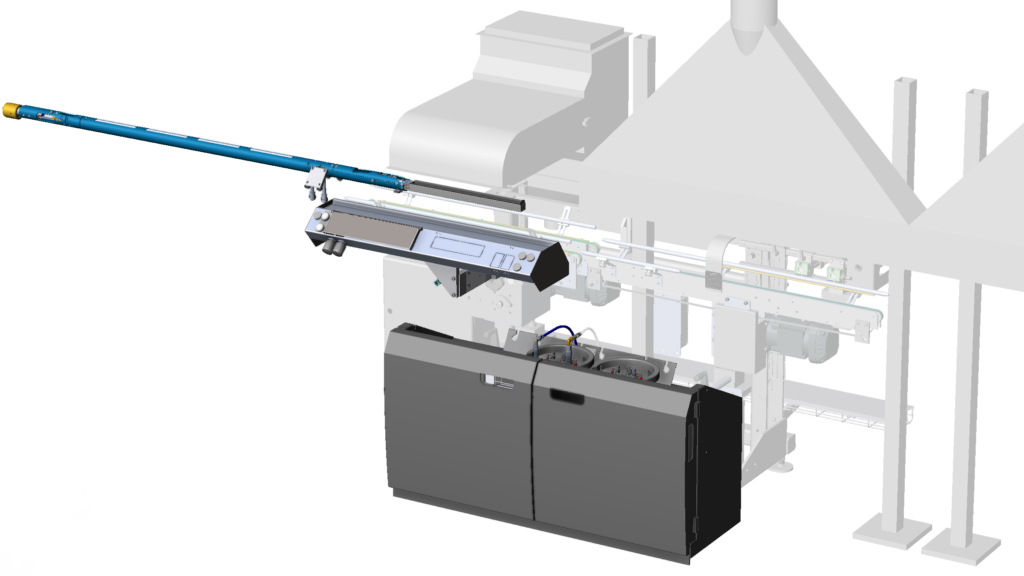

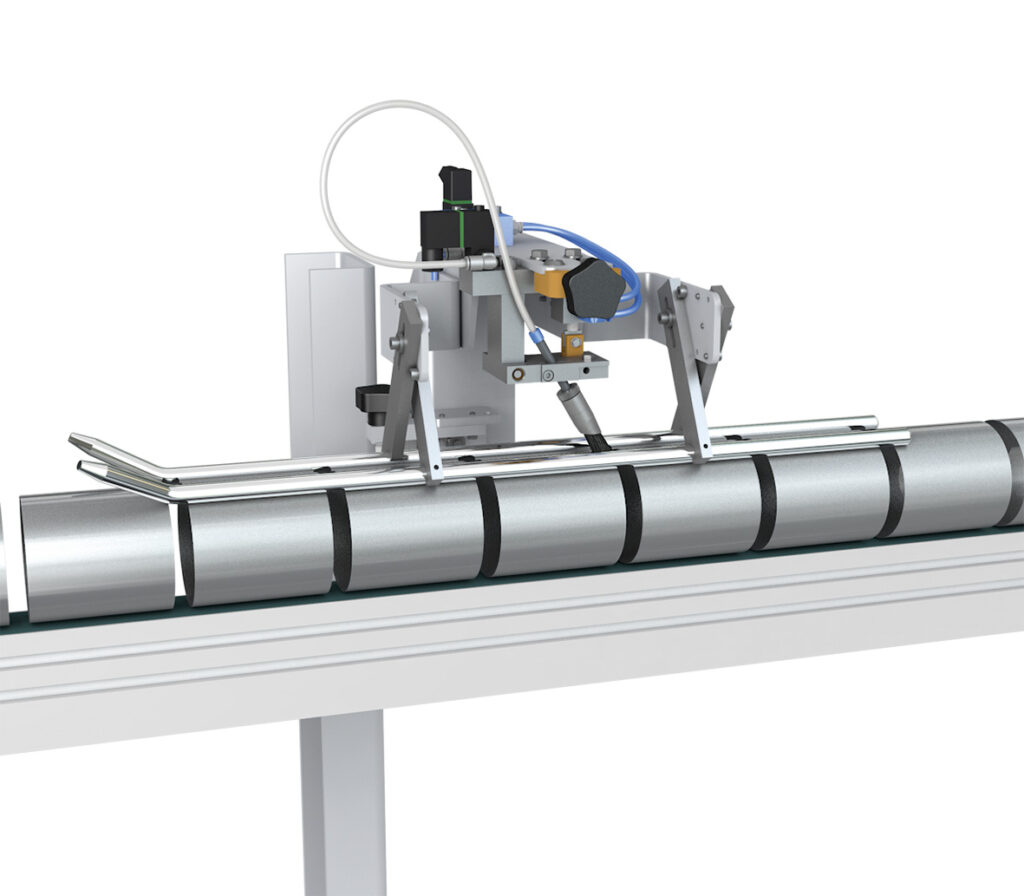

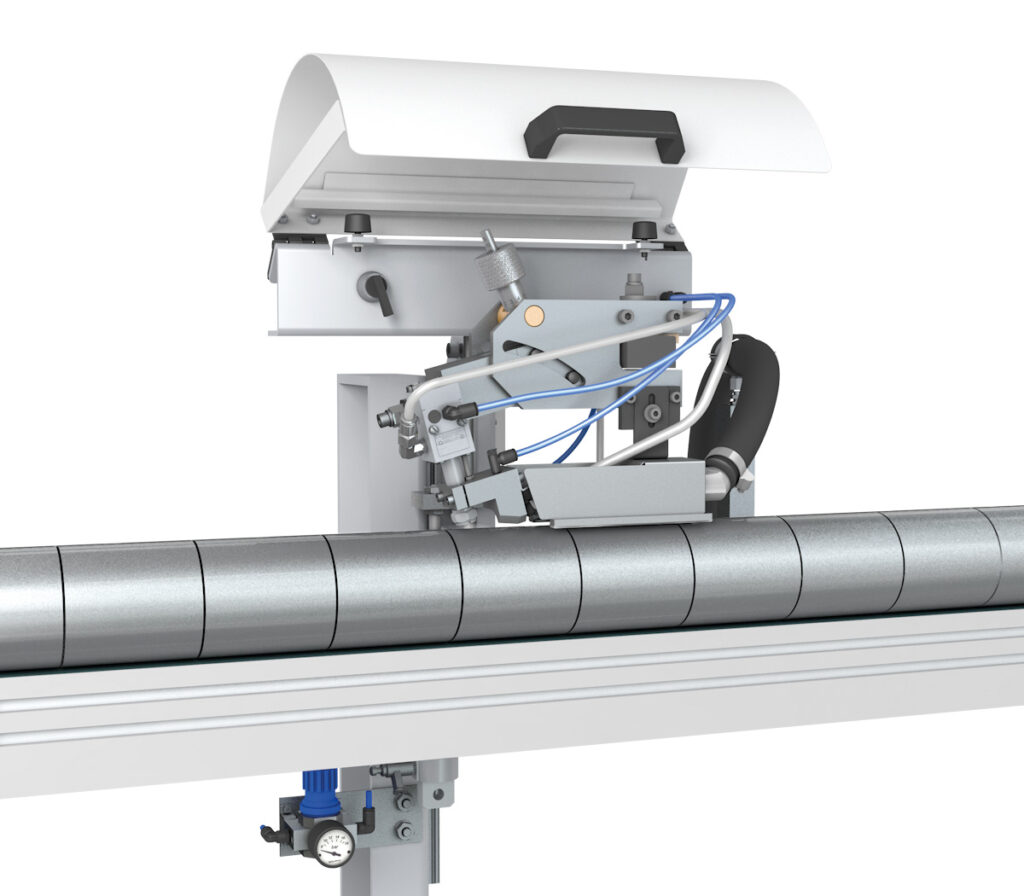

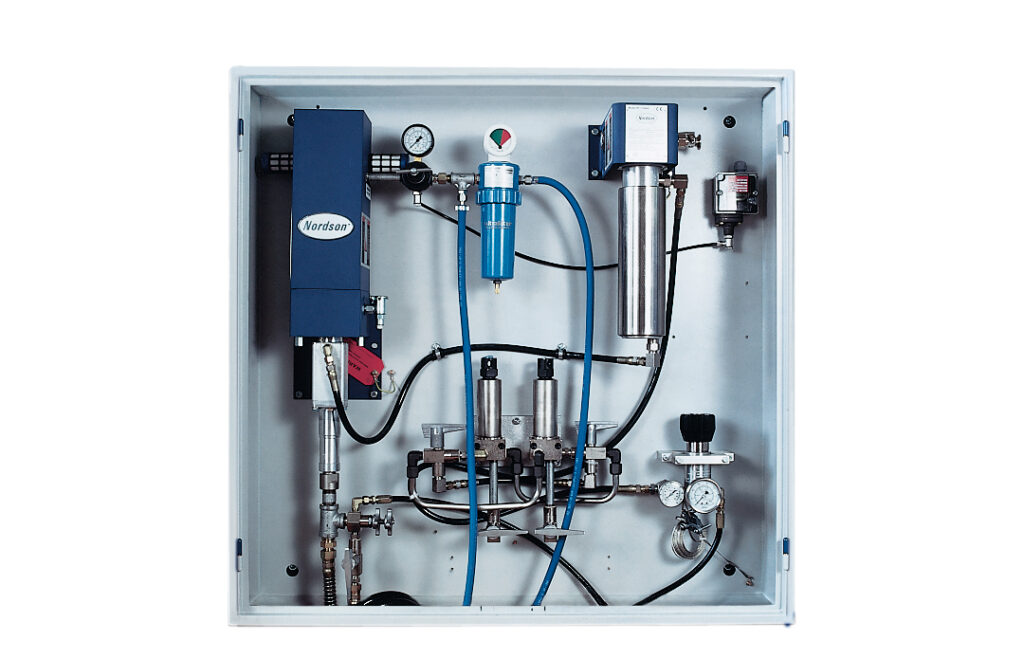

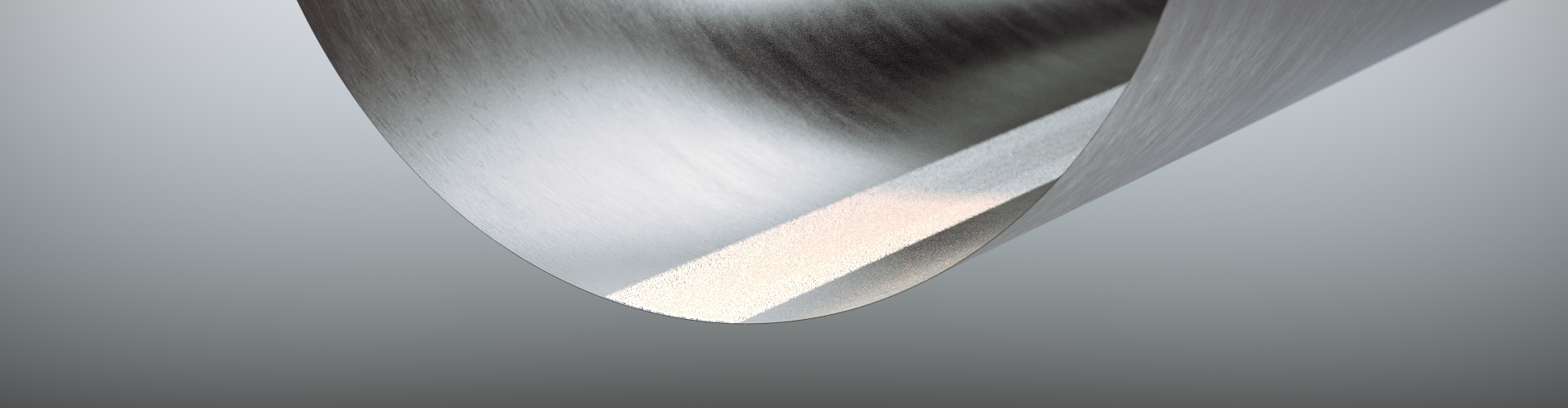

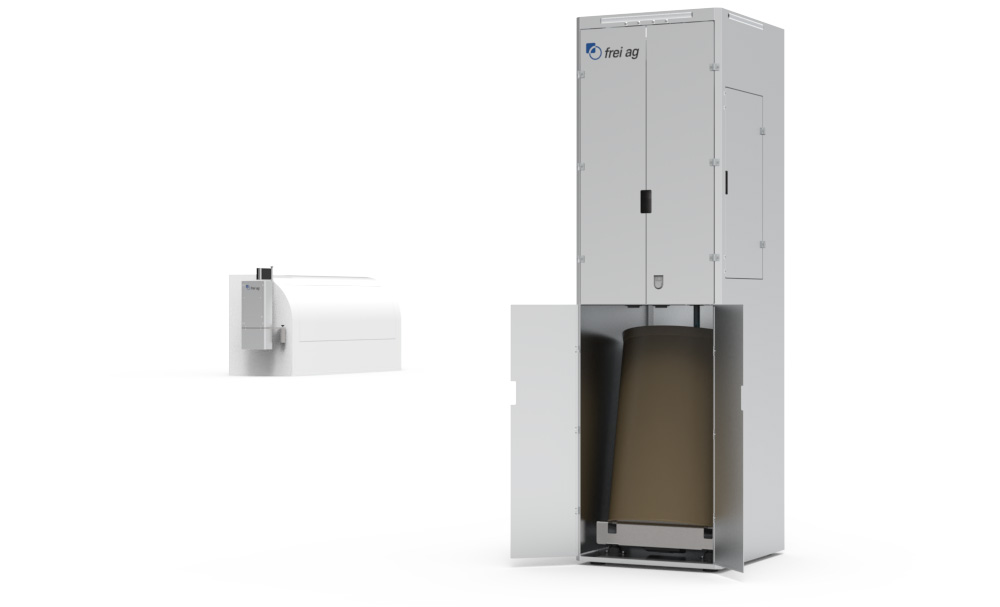

Effective protection of the weld seam is crucial to the quality of a three-piece can. That’s why we offer a broad range of seam protection technologies and systems. After welding, the next step in the manufacture of a quality can is the application of a durable protective layer to the inner and outer seams. We supply fully automated powder-coating or wet-lacquering systems for inner and outer seams.

Our seam protection systems can be customized to all system configurations, production speeds and canbody sizes. They guarantee easy, clean operation and low powder or lacquer consumption.

Location

Seam Inside

Seam Outside

Application

Powder Coating

Lacquer Airless

Lacquer Airspray

Roller Coating

Lacquer brush Coating

Weld position

top weld

bottom weld

Series

SOUCOAT P-80S / P-120S

PowerCOAT iP

PowerCOAT oP

PRC

ORC

ORC-BP

DRC

LNS

LAS

ANL

OSS

Series

Location

Application

Weld position

Technology

Welding speed [m/min]

Body Diameter [mm]

Company Brand

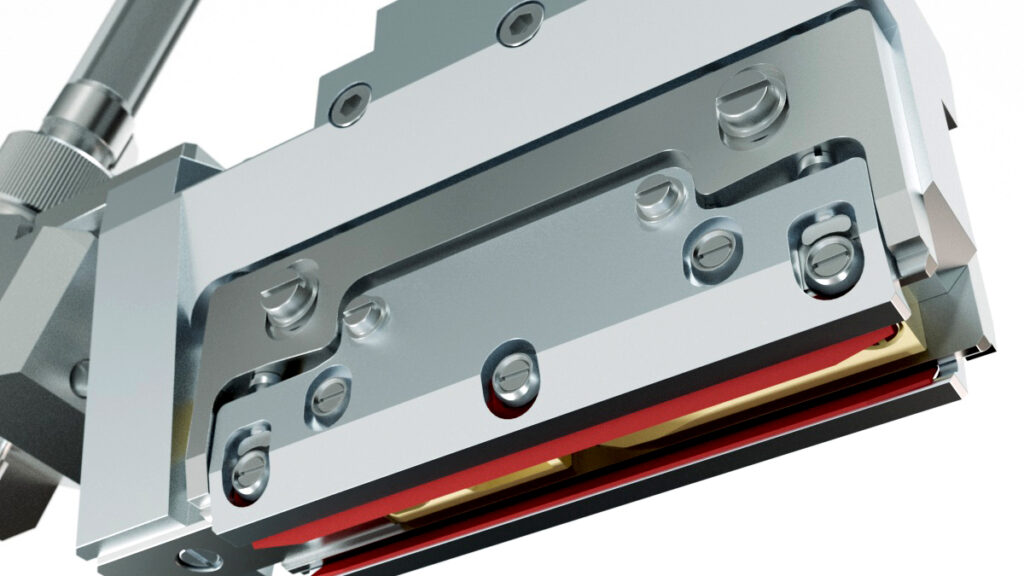

SOUCOAT P-80S / P-120S

Seam Inside

Powder Coating

top weld

Powder lacquer

9 – 115

45 – 330

PowerCOAT iP

Seam Inside

Powder Coating

top weld, bottom weld

Powder lacquer

10 – 100

52 – 330

PowerCOAT oP

Seam Outside

Powder Coating

top weld, bottom weld

Powder lacquer

10 – 100

52 – 330