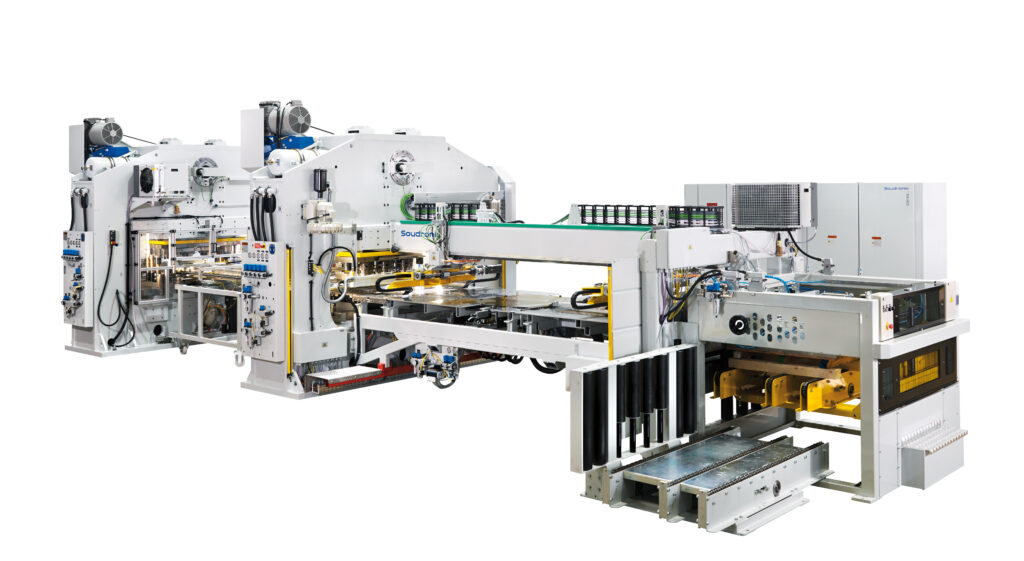

2-piece can making systems for ultimate flexibility

We build and install complete production lines of high performance DRD presses for deep-drawn round, conical, rectangular or irregularly shaped canbodies. The process of our UNIPRESS machine typically comprises several stages like stamping, pre-drawing, final-drawing, embossing, paneling and trimming. Finished cans are then ejected onto an outfeed conveyor which transports them to a packaging table or palletizer.

The CAN-O-MAT 2PC is a combined machine system with 1 to 4 stations for all forming and light testing operations to process DWI cans. All systems are designed and manufactured at our Swiss plant in Bergdietikon.

Filter Process

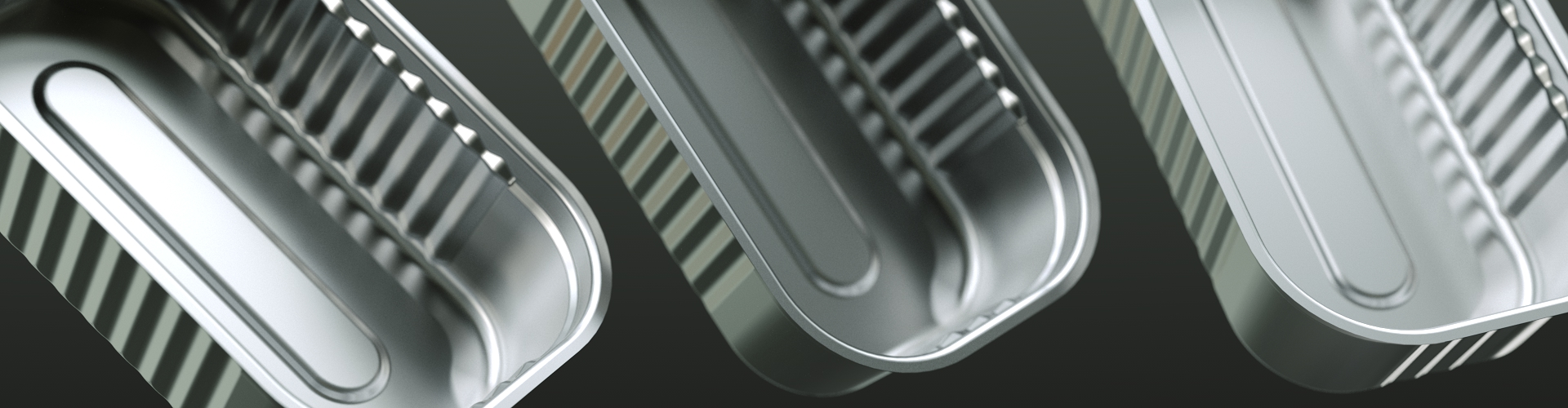

Canbody drawing

Canbody forming

Shape

Round

Irregular shape

Conical

Series

UNIPRESS

CAN-O-MAT 2PC

Series

Process

Shape

Capacity [cpm]

Dimensions Ø [mm]

Dimensions L x W [mm]

Height range [mm]

Spindles

Press force [kN]

Number of strokes /min.**

Sheet size max.

Sheet size min.

Sheet thickness [mm]

Company Brand

UNIPRESS UP + UNIPRESS RPT

Canbody drawing

Round, Irregular shape, Conical

Up to 750

50 – 99

60×40 – 155×85

Up to 55

Up to 800

80 – 150

1100 x 1100

650 x 650

Fe 0.14 – 0.25 AI 0.15 – 0.35