Calibrating Force Monitor

Thanks to the new Calibrating Force Monitor, all welding-related influences can be detected. Soudronic engineers have reached another major milestone that will boost production reliability in welding technology.

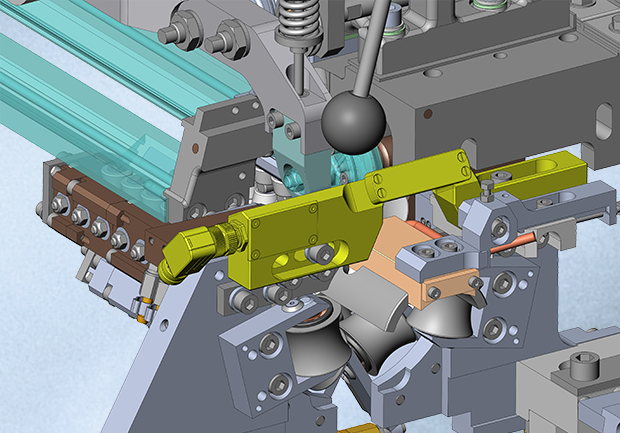

So far cold welds caused by overlap errors could not be detected. Even with perfectly adjusted shears, cut blanks can turn out too large. For example, this can happen if the tinplate exhibits pretension and does not lie perfectly flat during cutting. Excessively large dimensions in the sheet development direction result in excessive overlap. In this case, the welding current would have to be increased in order to prevent cold welds. Until now, no monitoring system on the market was able to reliably detect excessive overlapping due to dimensional fluctuations. The new Calibrating Force Monitor rounds out our well-proven SWM-3 system. Overlap fluctuations are now detected reliably and faulty can bodies are ejected. The basic principle of the Calibrating Force Monitor is simple. It measures the resulting force in the calibrating crown. There are no additional components at the machine. Force measurement is a built-in component of the UNITOOL. Overlap errors of 0.1 mm and more are detected. The CFM is extremely user friendly. It works similarly to existing monitor channels. The Calibrating Force Monitor is calibrated using a small batch of can bodies. With a single parameter, users can adapt the detection sensitivity of the Calibrating Force Monitor to their needs. The monitor system is maintenance-free. The two Energy and Calibrating Force Monitor systems detect all known weld faults. A heat monitor is no longer required. The excellent performance of the Calibrating Force Monitor has been proven in a variety of field tests. In short, we can say that poor quality cans caused by overlap fluctuations are now a thing of the past.

Customer benefits

- Can bodies with cold welds caused by overlap errors are detected and ejected

- The monitor signal lets users know that welding is set correctly.