About Metal Packaging

At Soudronic, we believe the canmaking industry has a responsibility to enlighten consumers about the largely unperceived ecological benefits of our products. If this helps to change consumer perceptions about metal packaging and push up recycling rates still further, we will already have taken a major step forward.

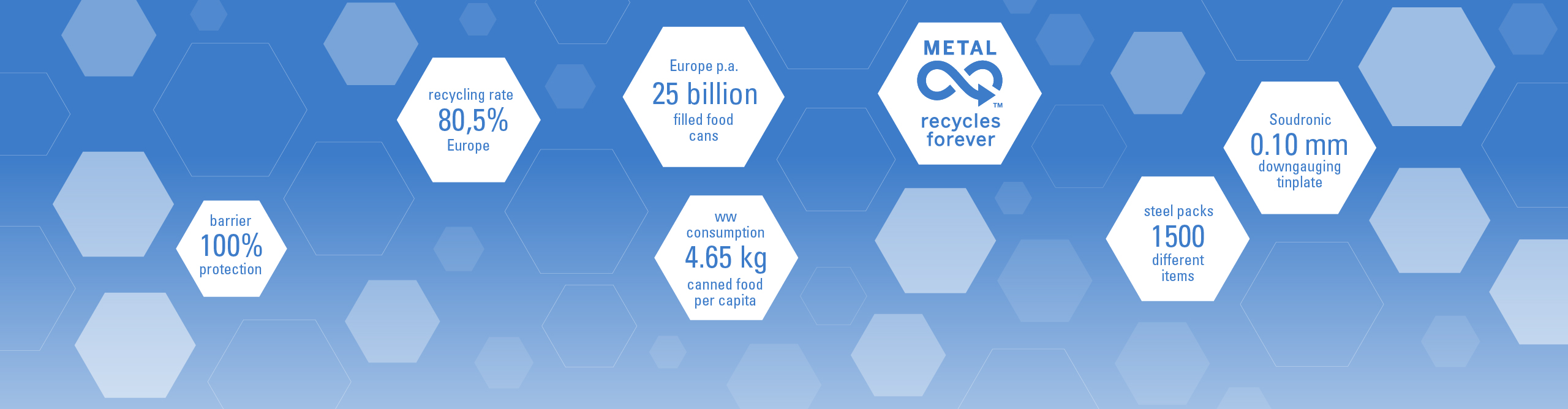

Downgauging to 0.10 mm

Metal is one of the most economical, environment-friendly and hence sustainable forms of packaging available to manufacturers today. And the arguments in its favor are compelling.

First and foremost is the fact that metal cans today require far less raw material than in the past. Soudronic leads the way in the development of the advanced can making machines needed to work with downgauged tinplate, i.e., sheet metal stock of as little as 0.10 mm in thickness.

Lighter cans mean more containers per ton of tinplate, savings on natural resources and, overall, a significant reduction in the world’s carbon emissions footprint.

Metal recycles forever

Made from an infinitely recyclable material, the can is easily sorted, efficiently recycled, and has a high end-of-life economic value, which make it a great example of a sustainable packaging option that is well-suited for real circularity. When it comes to sustainable but also safe and versatile packaging, it’s therefore pretty hard to beat cans.

Recycling Success of Steel Packaging

Apart from the technological advances that make metal packaging so attractive, steel has countless advantages that put it in an environmental class of its own.

Independently verified figures published by Steel for Packaging Europe confirm that 80.5% of steel packaging placed on the market was ‘really recycled’ in 2022. It follows the announcement in December 2023 that steel packaging had met its EU recycling rate target for 2025, four years ahead of schedule.