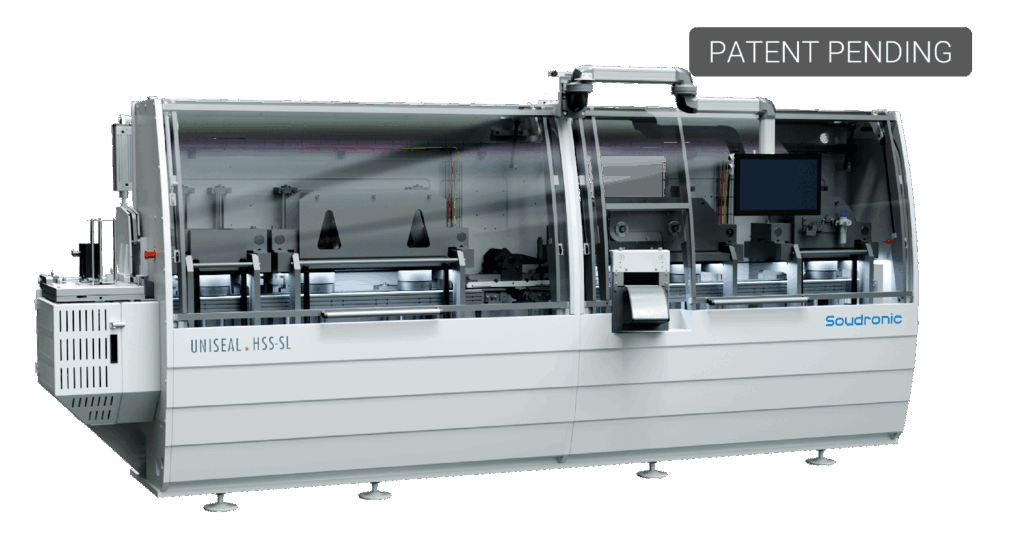

UNISEAL HSS-SL and peel-off ends

UNISEAL HSS-SL: Proven concept in action

What started as a prototype in 2019 has since evolved into a reliable production solution: the UNISEAL HSS-SL, our single-lane heat-sealing system, has now been operating successfully for over three years at SILGAN Metal Packaging—consistently delivering up to 200 peel-off ends per minute.

SILGAN had already integrated several multi-lane UNISEAL HSS sealing machines into its production lines. In 2021, the company chose to expand its capabilities by investing in a single-lane version—the UNISEAL HSS-SL. A key factor in this decision: the system’s unmatched flexibility and rapid format change capability.

«Our multi-lane sealing machines run smoothly and reliably for standard formats. With the single-lane system, we’ve gained a flexible solution that enables fast changeovers,» says Marco Prosdocimo, Head of Engineering at SILGAN.

Efficiency by design

Built on the proven UNISEAL platform, the HSS-SL delivers the same high standards of reliability and precision SILGAN has come to expect. However, its monobloc design—a compact integration of machine and control cabinet into a single frame—sets it apart. This space-saving construction simplifies both transport and installation. Upon arrival, only leveling, utility connections, and the attachment of the unwind unit for the peel-off foil were required. Once powered up, it was simply a matter of pressing the start button—and sealing began on day one.

Since commissioning, the UNISEAL HSS-SL has already produced millions of peel-off ends, operating with impressive consistency. «It’s been a dependable part of our production for years—often exceeding our expectations,» Prosdocimo adds.

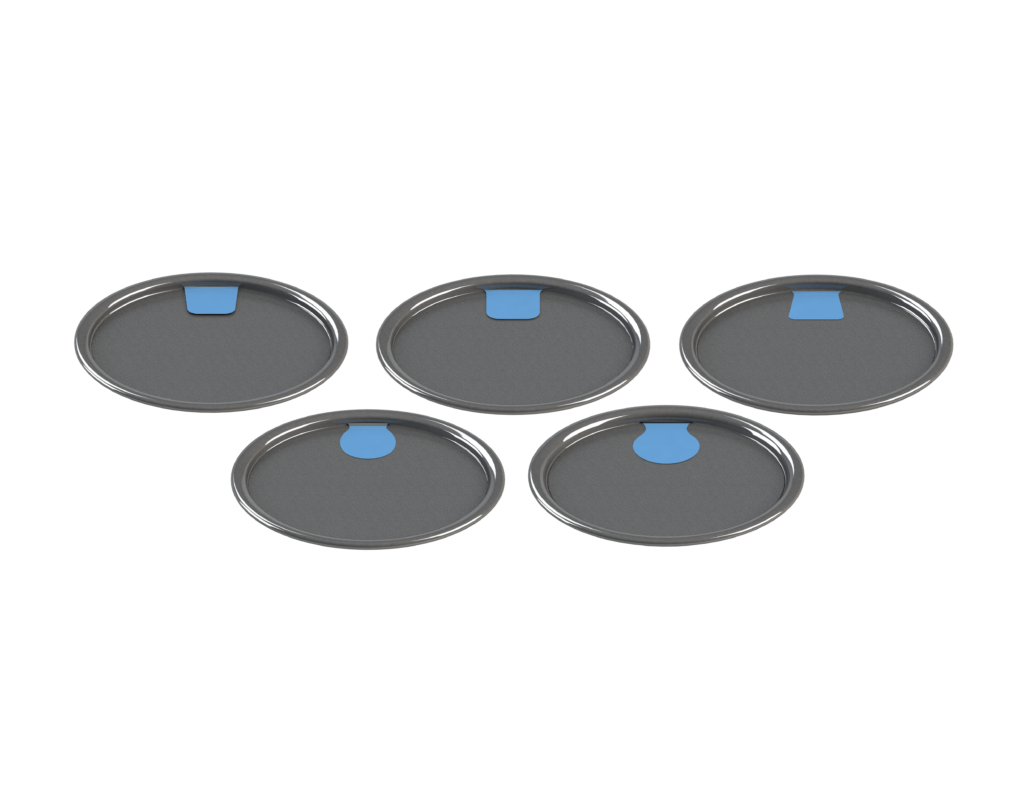

The UNISEAL HSS-SL is especially well-suited for demanding peel-off ends involving aluminum or steel shells, in both round and non-round formats. Sealing can be performed using either aluminum foil or transparent composite foil. A variety of tab designs are supported, including flat tabs and fingerhole tabs. For branding purposes, logos or design elements can be embossed into the aluminum foil.

UNISEAL HSS-SL at a glance

- High-flexibility and high-speed sealing machine for peel-off ends

- Designed for frequent format and product changes

- Ideal for peel-off ends market development

- Handles complex applications

- New innovative features and small footprint

- Ideal replacement for Rychiger machines of the MHM series