Optimizing curing processes

Oriental Tin Can relies on CURE.LOG.

In the competitive world of food can manufacturing, precision, and efficiency are paramount. Oriental Tin Can, one of the Philippines’ leading food can producers, understands this better than most. Recently, they integrated CURE.LOG into their production process, and the results have been impressive.

A leap forward in user experience

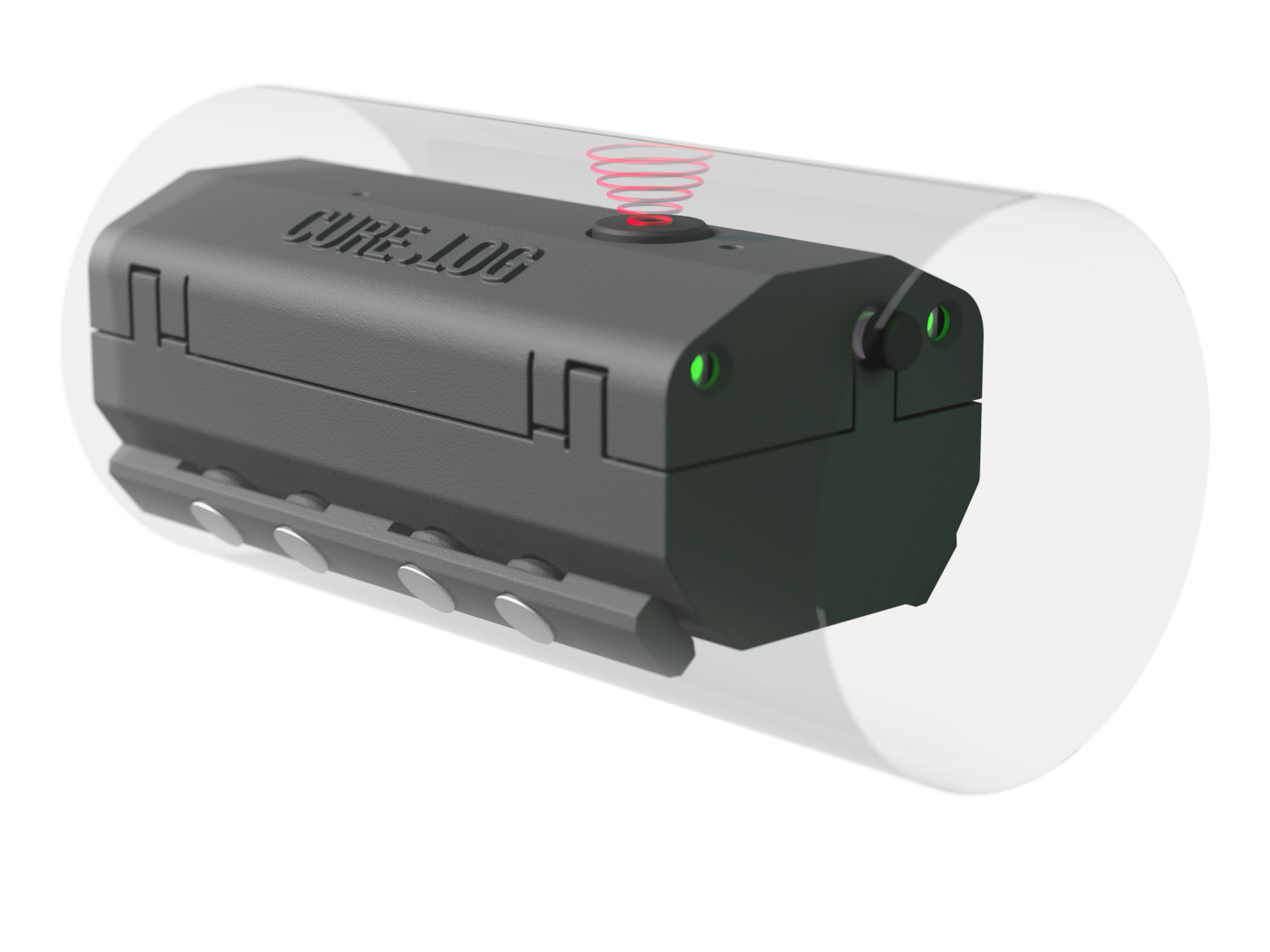

CURE.LOG is a state-of-the-art data logger that tracks the accurate temperature, torsion and shock of the can during the curing process. The thermal management in oven curing is critical for ensuring high-quality weld seam protection on cans.

«Switching to CURE.LOG has been a transformative experience for us,» says Benjamin de Guzman, Head of 3-Piece Can Operations of Oriental Tin Can (OTC). «It is significantly more user-friendly compared to the wired thermocouples we previously used.»

The shift to Soudronic’s advanced infrared technology has notably enhanced OTC’s workflow. The contactless optical measuring principle simplifies setup and ensures more accurate and reliable temperature readings that OTC can trust. By eliminating the inconsistencies and handling challenges associated with wired probes, this technology has streamlined OTC’s operations.

Intuitive interface and data visualization

One of the key advantages of CURE.LOG is its intuitive user interface. «The data visualization using the provided Excel template is clear and easy to understand,» says the production team. This allows the team to interpret curing profiles and make well-informed decisions swiftly. With effortless data analysis, OTC can monitor and optimize its processes more effectively.

Operational efficiency and reduced downtime

The comprehensive data provided by CURE.LOG allows OTC to adjust its production line quickly. «The ability to easily analyze and understand the data has significantly reduced our downtime,» notes Renz Llavore, Production Supervisor of Oriental Tin Can. This improved efficiency boosts productivity and minimizes costly interruptions, leading to a more streamlined and profitable operation.

Join the leaders in can manufacturing

OTC’s experience with CURE.LOG highlights the importance of reliable, user-friendly tools in maintaining high production standards. The ability of CURE.LOG to deliver accurate, actionable data has proven invaluable in their pursuit of excellence.

Discover how CURE.LOG can transform your production process. Experience the benefits of precise thermal management, intuitive data visualization, and enhanced operational efficiency. Join industry leaders like Oriental Tin Can in adopting a tool that not only meets but exceeds the demands of modern can manufacturing.