Turnkey can making systems

We provide a complete range of machines and components for the can making industry focusing on three-piece and two-piece can production lines and end making systems. Our machines cover the entire manufacturing process. Today, with more than 15,000 machines and system components installed, our production systems can be found virtually all over the world.

Our products

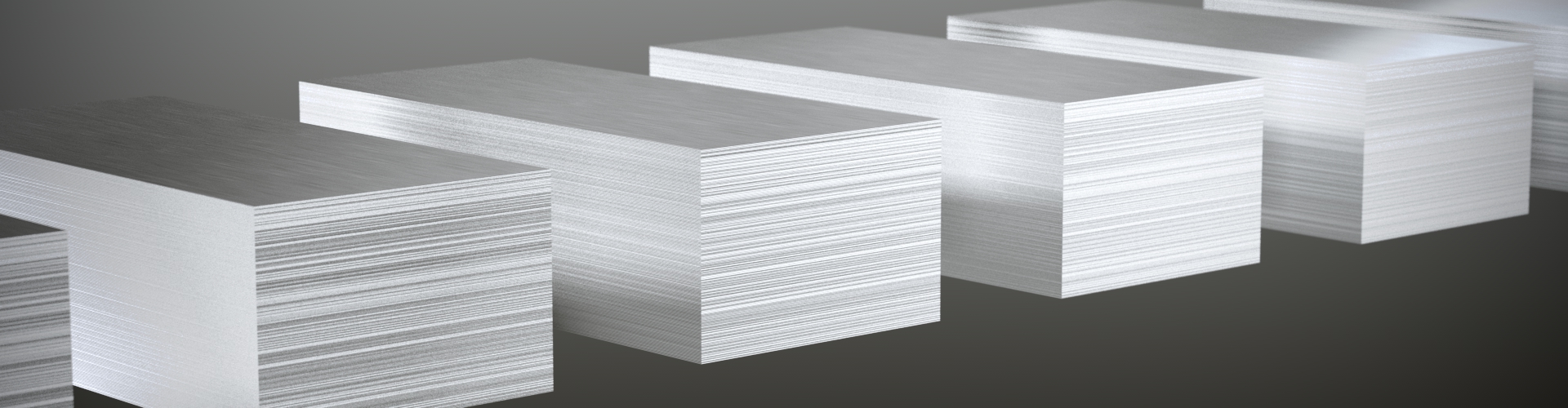

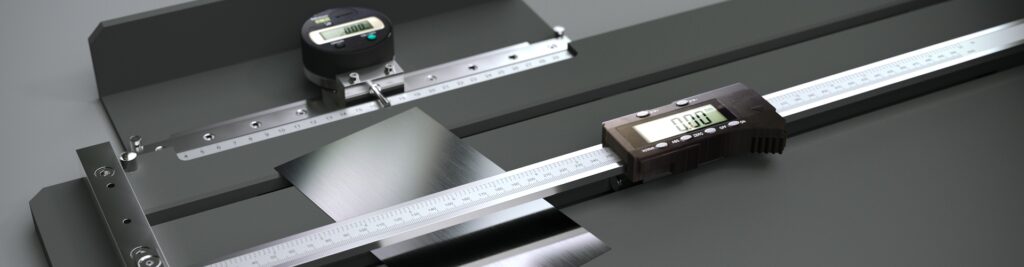

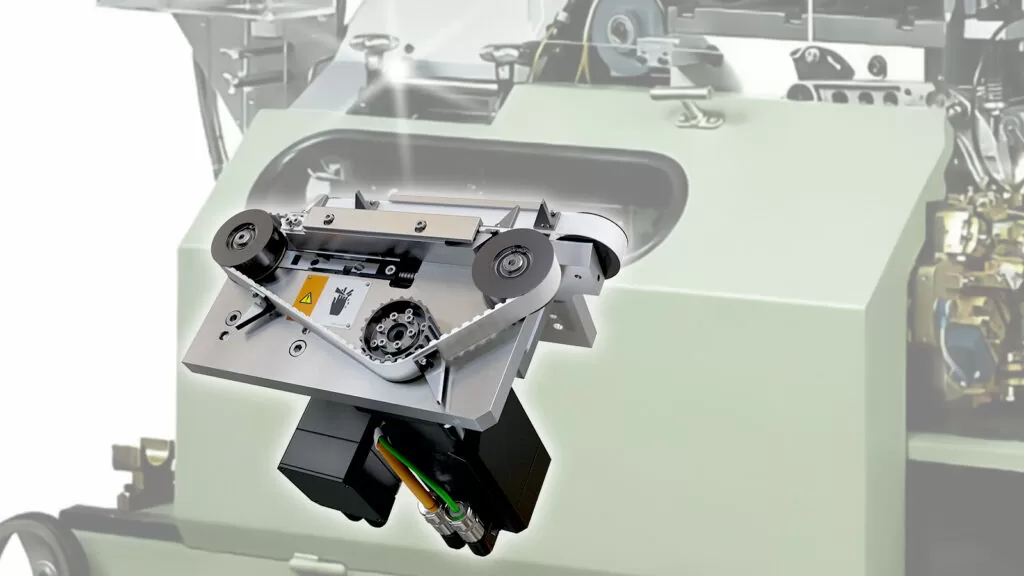

We design, manufacture, install and maintain fully integrated canbody production lines, operating from very low speeds to a maximum of 1,200 cans per minute, to produce cans, pails, drums and irregularly shaped metal containers. The range of machines contains slitters, transfer systems, welding machines, seam protection and curing systems, bodyformers and seamers, two-piece can production lines, endmaking and peel-off systems.

Products

News

-

Season’s Greetings from our CEO

Dear customers and partners, as the year comes to an end, I would like to take a moment to reflect on what has been an intense and challenging year for all of us.

-

On-call teams and local office availability 2025 / 2026

Need support? Here’s how to contact our on-call team during the holiday season. It also provides an overview of all subsidiary closures throughout the holidays.

-

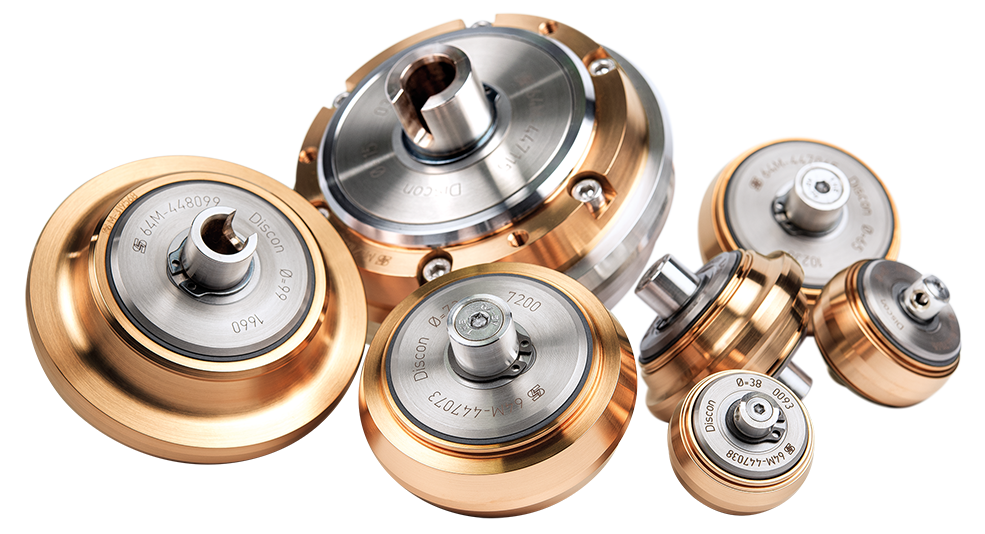

Phase-out «ARTER» gearboxes – LAST CALL

As of June 2026, our supplier will end the production of «ARTER» gearboxes. At the same time, revisions and servicing for these gearboxes will also no longer be offered.

Events

Our services

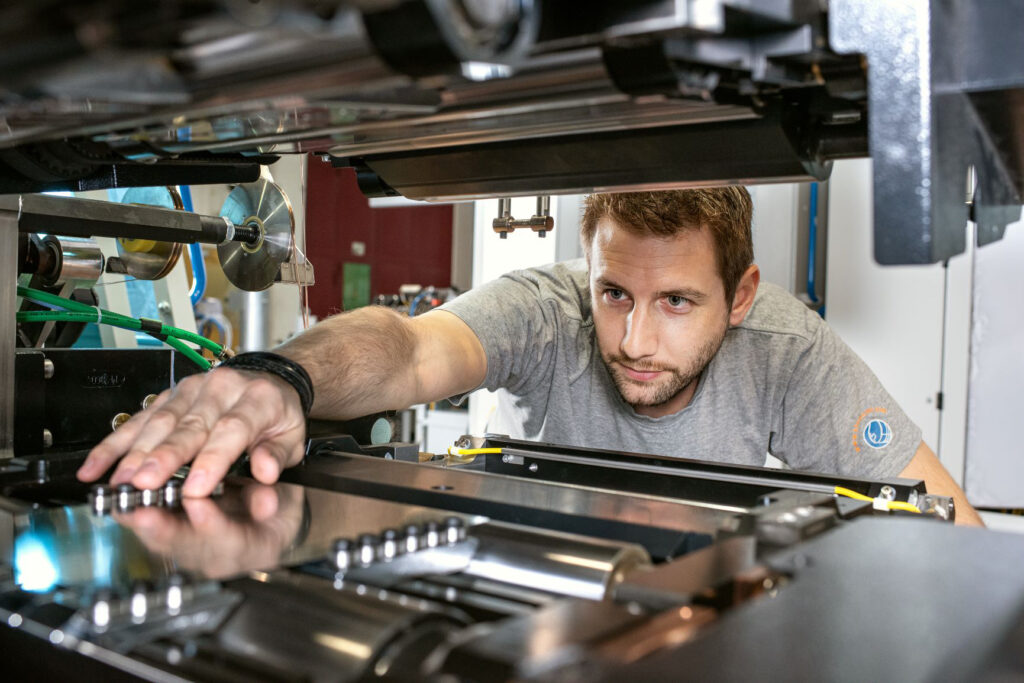

Customers learn the meaning of Soudronic support long before they sign a contract. We listen to their needs, suggest solutions, and accompany them throughout the entire decision-making process. Our service starts with the delivery of the machine or system and continues for the entire duration of its productive life. We make sure that our customers’ systems run smoothly by providing training programs for operating personnel and support through our skilled technicians. We provide a comprehensive inventory of 30,000 genuine spare parts and standardized solutions for upgrades and conversions.

Services

Explore our World of Factories

Dive into our 3D-world showcasing complete can production lines. Explore our high-speed performance or flexible three-piece can making lines. Move through the buildings to discover end making or two-piece can making systems. Learn more about our great upgrades and conversions offers that will ensure the productivity of your valuable installations.

Career@Soudronic

At Soudronic Group, with a team of over 500 professionals across 11 countries, we are always seeking talented individuals to join us. Whether you’re just starting your career or looking to take it to the next level, we offer exciting opportunities in various areas like engineering, assembly, manufacturing, maintenance, administration, sales or customer service.

About Soudronic

Founded in 1953, Soudronic is headquartered in Bergdietikon, near Zurich. Today, the company employs approximately 500 people across its development and production facilities worldwide. The Soudronic Group combines international brands and subsidiaries.

About Metal Packaging

At Soudronic, we believe the canmaking industry has a responsibility to enlighten consumers about the largely unperceived ecological benefits of our products. If this helps to change consumer perceptions about metal packaging – and push up recycling rates still further, we will already have taken a major step forward.

Certificates and Awards

Our achievements reflect a strong commitment to quality, innovation, and customer satisfaction. We continuously strive to enhance our offerings and meet evolving industry demands. This commitment is reflected in the reliability of our products and the ongoing improvement of our processes.