Shielding gas monitoring

New electric monitoring of the gas flow rate immediately recognizes malfunctions and enables effective quality control.

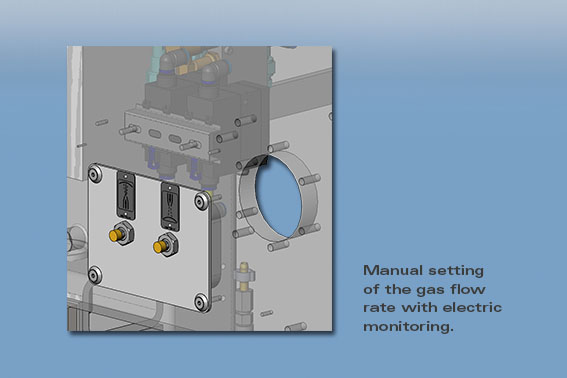

Applying nitrogen to the weld seam prevents the formation of an oxide layer that would lead to inferior lacquer adhesion. If the gas flow rate falls below its minimum level as the result of an empty gas container or a leak, the affected cylinders are ejected, the machine switches off and the control panel displays an error message. The gas flow rate is set using the control valve on the front plate. The current flow rate and the monitored minimum rate are displayed on the UNICONTROL touchscreen.