UNIPROFILER

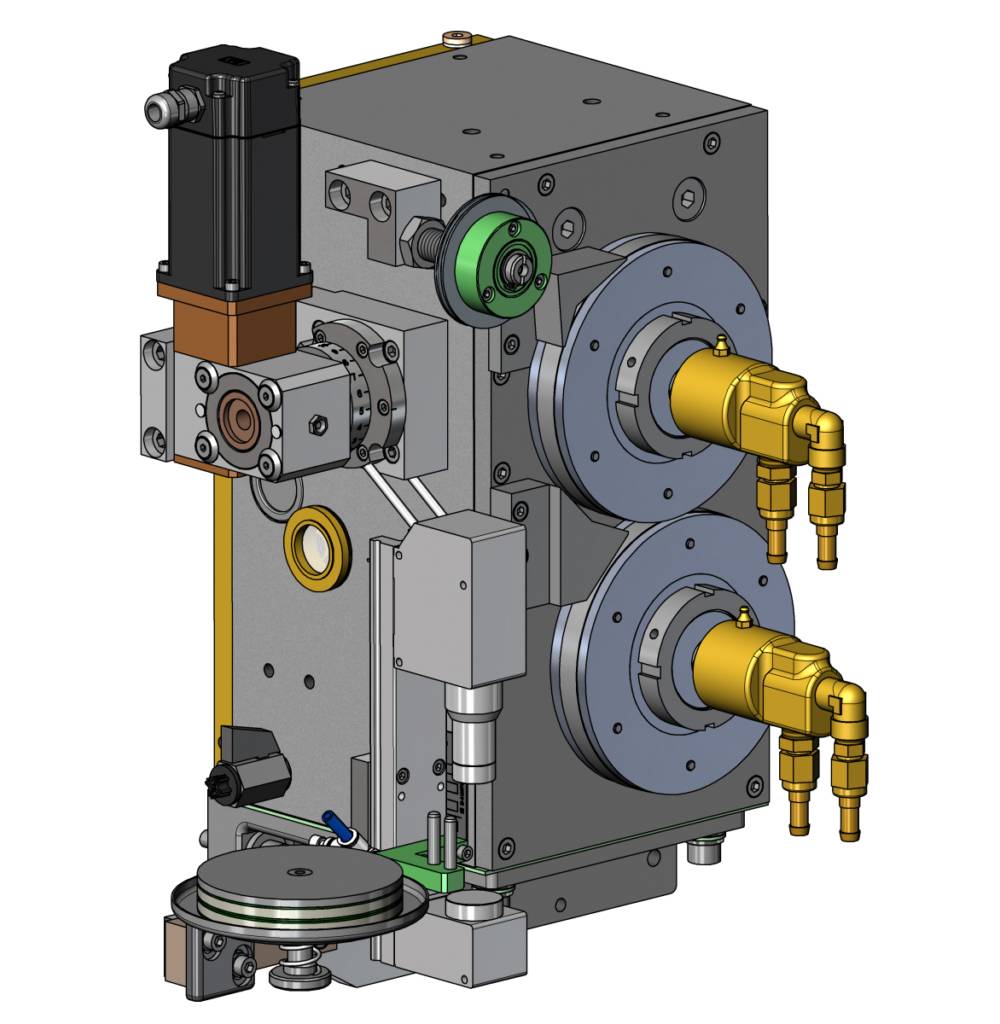

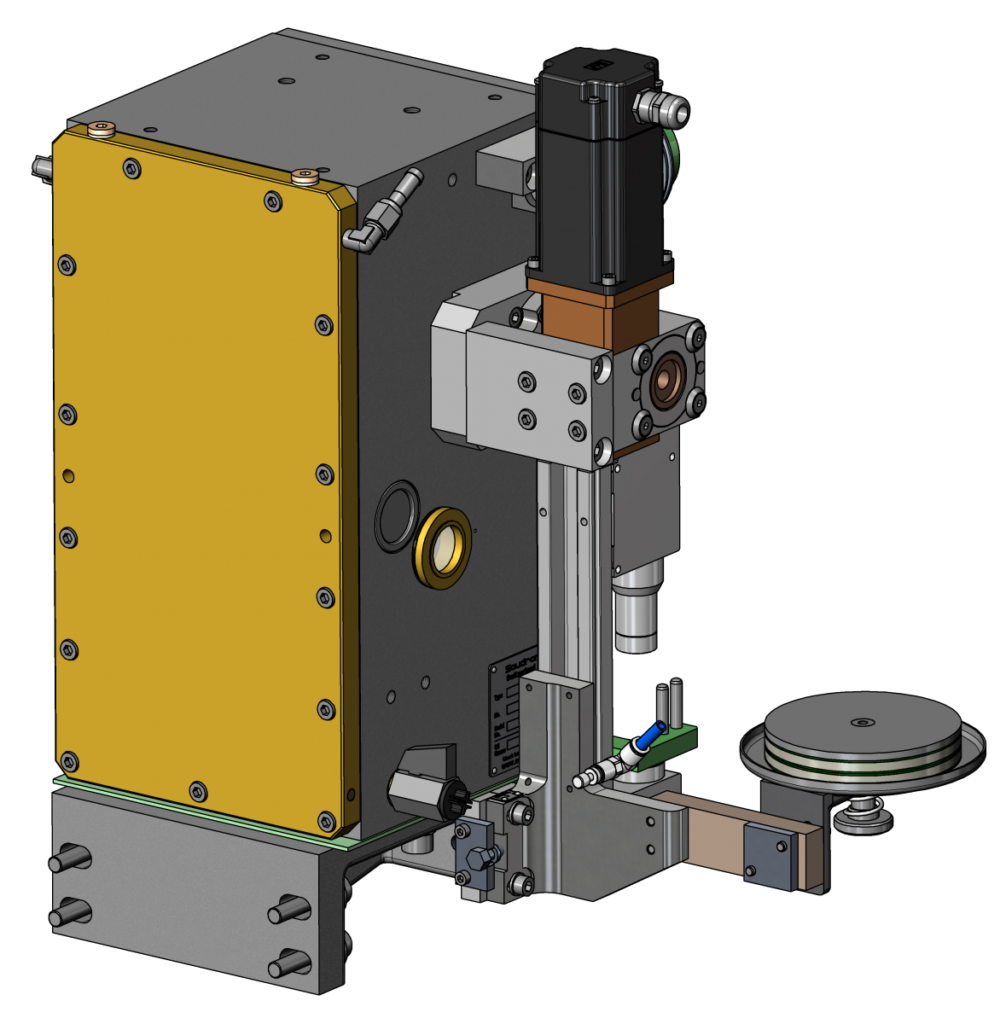

As machines become faster and faster, wire profile requirements become increasingly stringent too. This is also true of the wire width consistency, in order to achieve constant conditions at all times during welding (particularly in order to maintain a constant canbody gap). The Soudronic copper wire specification requires a maximum diameter tolerance of 0/- 40 μm. The new UNIPROFILER system allows for fully automatic compensation of variations in wire diameter.

Function

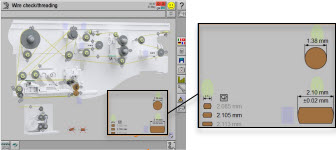

After wire profiling, the wire width is measured using a high-resolution sensor and corrected accordingly via the servometer. If deviations in wire width are too great, the control unit outputs an error message. The exact values and the average are displayed on the UNICONTROL “wire setup” page. The “wire diameter” and “permissible deviation” values are parameterizable.

Advantages

- Improved line efficiency due to fully automatic readjustment by motor-driven regulation of wire width for the wire profiling unit

- No more tedious measurement and correction of the wire width

- Constant wire width profile measured and corrected in real time

- More consistent welding quality

- Less variation in canbody gaps

- Increase in roller head service lives

(sample of the UC2 display below)

Retrofitting

UNIPROFILER can be retrofitted on all

machines dated 2007 or later:

- AFB 600

- AFB 800–1000

- FBB 800–1000

- SOUCAN 600–2000

Older machines: on request.