Rounding Measuring Device (SRM)

Soudronic now offers the diagnostics functionality of the Adaptive Rounding System (ARS) as an individual feature under the name Soudronic Rounding Measuring Device (SRM). Cost pressure is forcing canmakers to increase line efficiency. The demands made of machine operators are increasing, and fast error correction is becoming ever more important. For example, without the Adaptive Rounding System (ARS), it is impossible to detect yield strength variations in welding machines.

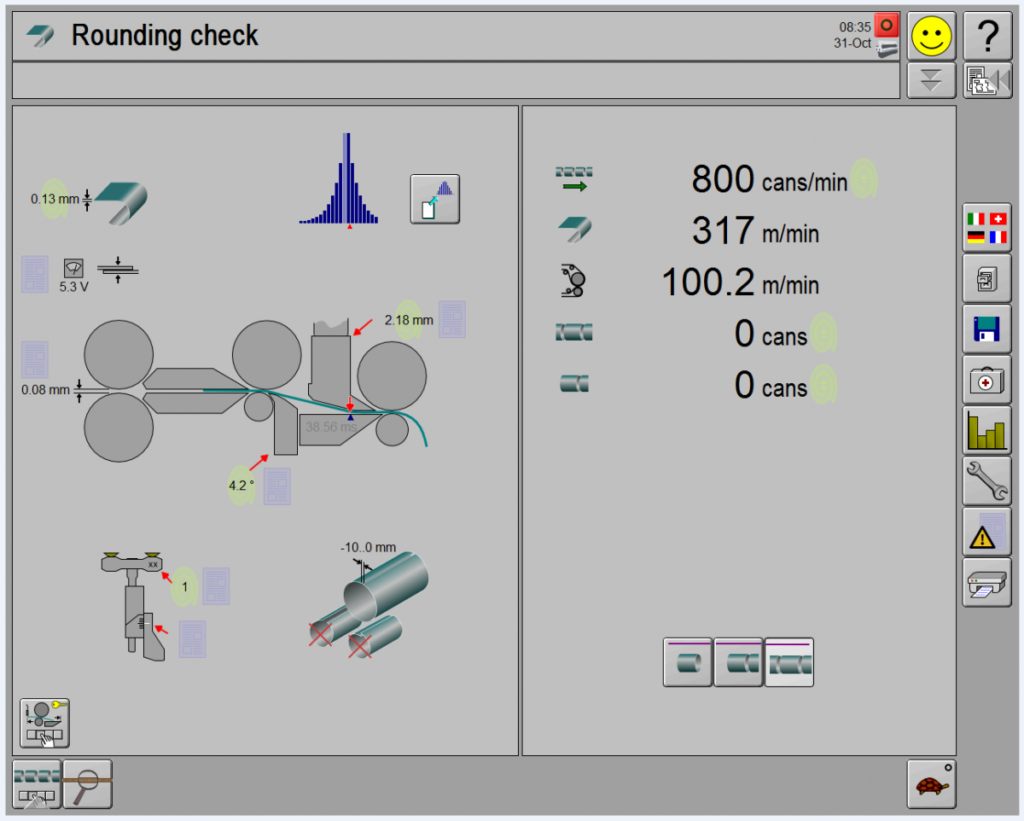

The Rounding Measuring Device (SRM) enables the operator to detect yield strength variations quickly and to adjust the rounding machine accordingly. The Rounding Measuring Device (SRM) also visualizes the flexer operation for the operator.

The material characteristics of each cut blank are detected using the in-line measurement familiar from the Adaptive Rounding System ARS and shown on the UNICONTROL display. The Gant chart clearly depicts the variation in the rounding property. Material mixtures or pre-processing quality problems are detected. The visualization can be used as the basis for quality improvement measures.

As an additional benefit, the flexer function is visualized. It shows where the cut blank appears on the flexer plate. Illustration of the target position makes it much easier to carry out the correct setup

Advantages

- Yield strength variations in the material are visualized and quickly detected

- Greater line efficiency thanks to faster intervention

- Better product quality due to more precise flexer setting

- Operator guidance through visualization of the setpoint during flexer setting

- Statistical recording of the yield strength variation on the UNICONTROL

Retrofitting

- Retrofits are possible on the latest machine generation

- Older machines on request