Benefits Of The Pacemaker

Compatibility

The Pacemaker with its latest digital technology replaces old mechanical (motor driven) frequency generators, but recently also more and more old static inverters. Due to its compatibility Pacemaker is your solution for any welder in your factory.

Installation & Setup

The installation is easy and may be done by a well educated electrician. After the mechanical installation, a defined impulse can be activated, which measures the actual machines inductivity and limits the power as well as the possible weld frequency. 1 to 2 days and you are ready to restart production.

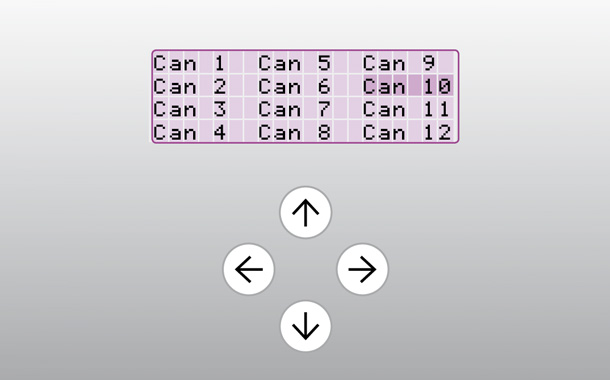

Preset Mode

This feature is very important for canmakers which are running different cansizes, materials or speeds. All welding parameter (in combination with our frequency drive upgrade even welding speed and production speed parameters) can be stored and recalled when running the same can another time.

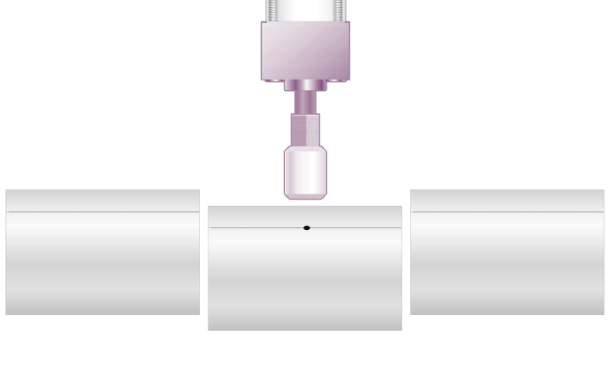

Integrated Overlacquering Control

On one of the windows of the operators panel of the «Pacemaker» you can set your «welding limits» in percentage of the adjusted welding current. If some lacquer or any other «insulator» or mechanical misadjustement or damage passes the welding zone, the unit immediately reduces the current and indicate a warning. If this happens to often during a production sequence an output will command the destacker to stop.

Quality Control

The provided digital in- and outputs enable a connection to the Can Man Qualimaker or any other weld monitor system you may have installed on your welder. If there’s no weld-monitor installed, an optional can rejection kit can be supplied and connected.

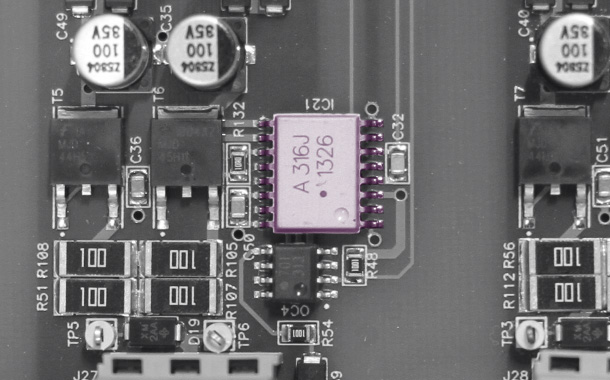

Short Circuit Protection

Old or low quality welding transformers bear a high risk towards a short circuit. Pacemaker is equipped with a high speed protection which senses in nanoseconds such a destructive event and shuts the current off instantly. This prevents a damage of the Pacemaker and its electronic components.

Technical Data

| Welding frequency range | up to 1000 Hz |

| Peak current | 400 A (Pacemaker400) |

| Power | 3 x 400 V / 50 / 60 Hz |

| Cooling liquid supply | liquidcooled semiconductors, temperature controlled |

| Water pressure | 5 bar (absolute) |