OSS outside spray system

Contact-free lacquer application stands for undemanding setting. Thanks to the low application pressure the OSS environment remains clean. OSS is the new high performance alternative solution.

Low pressure application meets high-speed

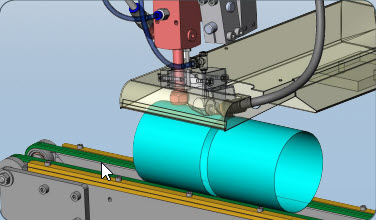

The use of the OSS permits the contact-free application of lacquer to the external seam of the can body. Unlike standard roller coating systems, the spray system is less sensitive to differences in speed and can body diameters. The OSS is well suited to high application speeds and delivers a very good lacquer coating in the seam overlap area.

The default lacquer viscosity for the system is 12 – 18 sec DIN4. To assure a smooth and trouble-free production, these values must be met.

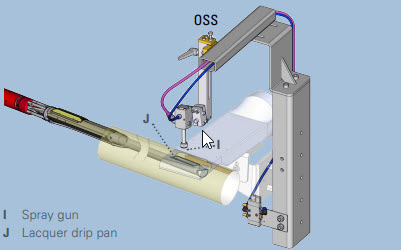

The container, filled with liquid lacquer, is put under pressure, which transports the liquid lacquer through the system to the spray gun. The sensor detects the can body as it approaches and transmits a control pulse to control valve, which activates the lacquer spray though spray gun I.

injector

A Suction injector

B Control valve, injector air

C compressed air line

D Suction line, injector

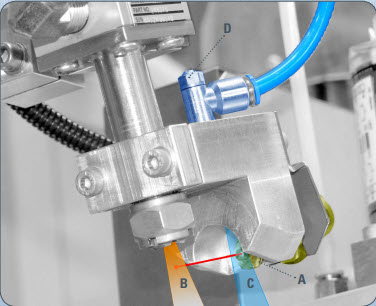

- The sensor A monitors the presence of lacquer in the spray jet B.

- Air jet C protects the sensor lens against dirt and can be set with throttle D.

A line stop is triggered if:

- there is little or no lacquer at all

- the nozzle is clogged

- the lacquer tank is empty

- the pressure in the lacquer tank is too low

Advantages

- Suitable for all can body diameters

- Adjustable spray width

- Adjustable spray angle

- Ideal for high application speeds (also suitable for low application speeds)

- Contact-free lacquer coating

- Can be switched on/off at any time

- Different spray nozzles may be used

- Simple operation / adjustment

- Good coverage in the seam overlap area

- Automatic recognition/error message when lacquer level is low and/or supply disrupted => Low can body spoilage rate

- Independent of can body shape near seam

Retrofitting

Systems with UNICONTROL 2 or 3 can be retrofitted (design assignment necessary).