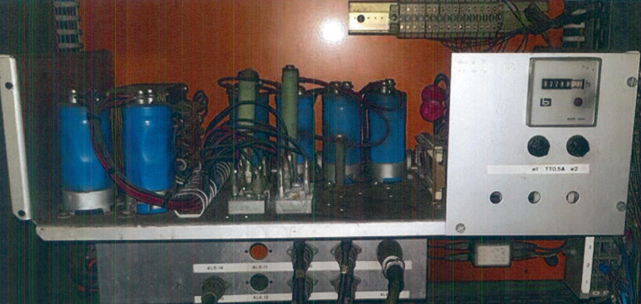

New power supplies for electronics

Different DC power supplies were used in the control circuits for old welding machines (built before 1982) with Philips control (± 12 V DC, 24 V DC, 28 V DC, 36 V DC, 48 V DC). Regarding spare parts, it is no longer possible to supply these power supply units for old welding machines with individual electrical or electronic components because many of the components are no longer available.

At the same time, it is essential to have a stable and fault-free DC power supply in the machine since it may has a direct impact on the quality of the end product (welding current dropouts)

Advantages

- Long service life

- Minimum operating costs

- Space-saving design

- Minimal wiring requirements

- No voltage matching (primary voltage) with transformers necessary

- Primary and secondary voltage fuse protection of the electric circuits

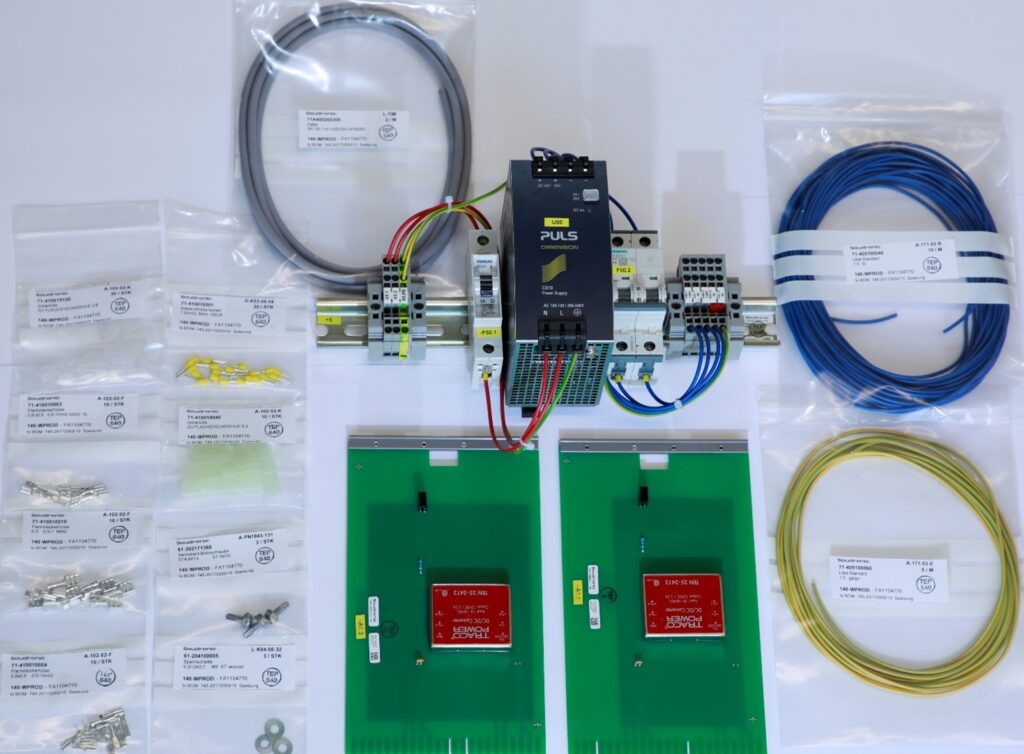

New Power Supplies

Highly reliable and easy-to-use power supplies for different output voltages (± 12 V DC, 24 V DC, 28 V DC, 36 V DC, 48 V DC) in a compact design. Thanks to their high degree of efficiency, space-saving design, long service life and resulting low operating costs, these new solutions with DIN rail power supplies represent the optimum solution for you. With a large input voltage range of 100 to 240 V AC, they are ideal for a multitude of applications, irrespective of the supply voltage and frequency.

Upgradeability

The new power supplies can be fitted or retrofitted on any machines equipped with a ± 12 V DC / 24 V DC / 28 V DC / 36 V DC / 48 V DC power supply unit (with Philips or relay control), simply by replacing the components. In the case of a bipolar, symmetrical ± 12 V DC power supply, the old plug-in modules in the rack are replaced with the new plug-in modules. This solution reduces the necessary wiring to a minimum since the plug-in modules are pin-compatible.