Monitoring SWM-3 with energy channel

Meeting highest quality demands

The weld monitor is available as stand-alone version and retrofit set for older welders.

SWM-3 Weld Monitor

In addition to all OCR-R functions SWM-3 provides integral assessment of the weld seam quality.

It is equipped with a user-friendly graphical touch-screen operating panel. Set-up is made by recording reference measurements over a series from 3 to 10 canbodies. Information of each ejected canbody is displayed on the monitor screen. Data of the last 12 canbodies, faulty or good quality, are registered and can be recalled at any time. The SWM-3 monitor is equipped with the energy measuring channel as a standard. Optionally it can be equipped with the heat channel to cope with highest detection requirements.

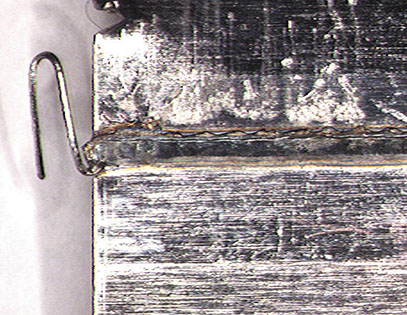

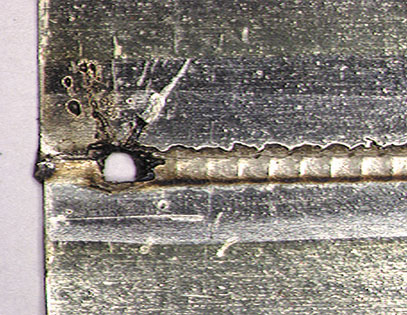

Energy Channel

The weld seam is monitored based on the weld energy.

The energy supply to each individual weld spot is measured and continuously evaluated. In case of weld parameter fluctuation, the set-up of reference measurements can be repeated during production.

Working principle:

The energy value of each weld nugget is calculated by sampling the voltage drop between the weld rollers and the welding current. Compared with the OCR-R functions, it also detects faulty seams, body offsets and variations of the overlap.

Advantages

- Highest reliability

- Effective quality supervision of the weld seam

- Online monitoring

- Integrated help system

- Fast return on investment due to time, material and money saving

- Meeting highest quality demands