Cut-Scoring

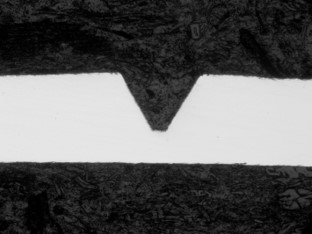

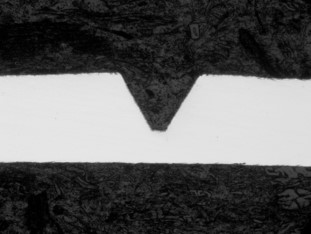

A method for scoring can bodies when standard scoring (V-scoring) reaches its limits.

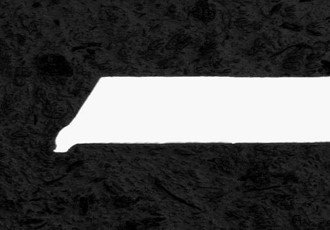

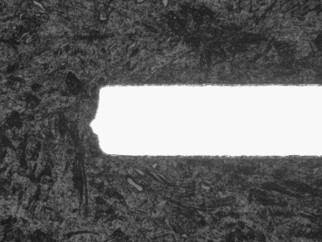

In cut-scoring the cold deformation of the material is much lower. The remaining ductility is therefore much higher than in V-scoring, which is preferable for necking and flanging. In the cross-section, the remaining wall strength is symmetrical in the neutral fibers. This facilitates the parting process. The break edge is thus much smaller. The small burr enables excellent neck and flange results with extremely thin sheet thicknesses.

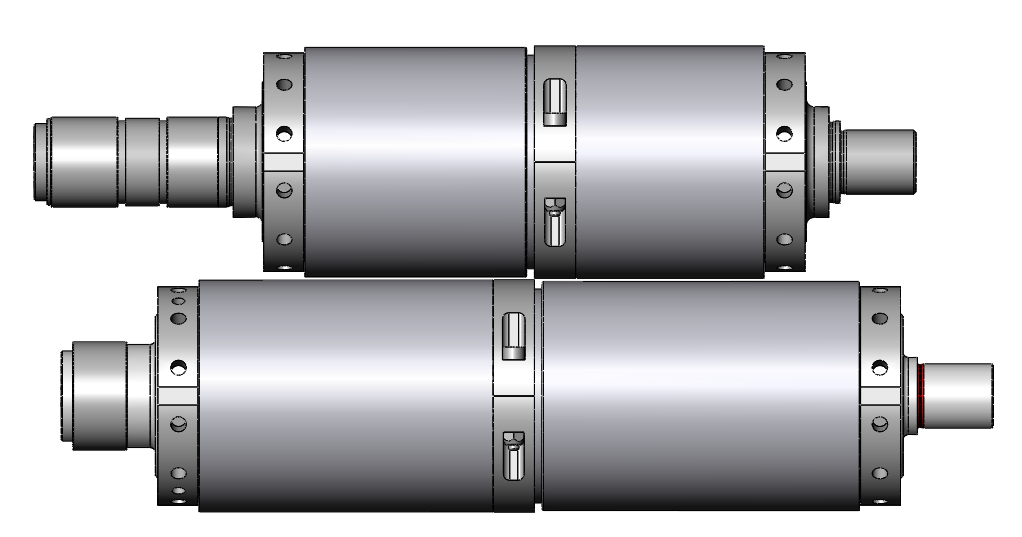

The SOUCAN 600/700/800/1000/2000 servies are capable of cut-scoring.

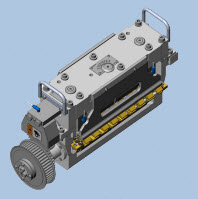

The design structure is similar to the V-scoring unit. The main advantage compared with V-scoring, however, is that the scoring position, depth and blade gap can be set outside the machine.

Advantages

- Easy processing of material thicknesses to a minimum sheet thickness of 0.10 mm

- Initial settings can be made outside the machine. This saves on refitting time

- Lower process force when parting

- More flexibility with product design because the scored end of the can body has perfect neck and flange properties

- The scoring blades can be re-grinded and sharpened on the end face (compared with V-scoring)

Retrofitting

Cut-scoring can be retrofitted on all SOUCAN 600/700/800/1000/2000 machines that support V-scoring.