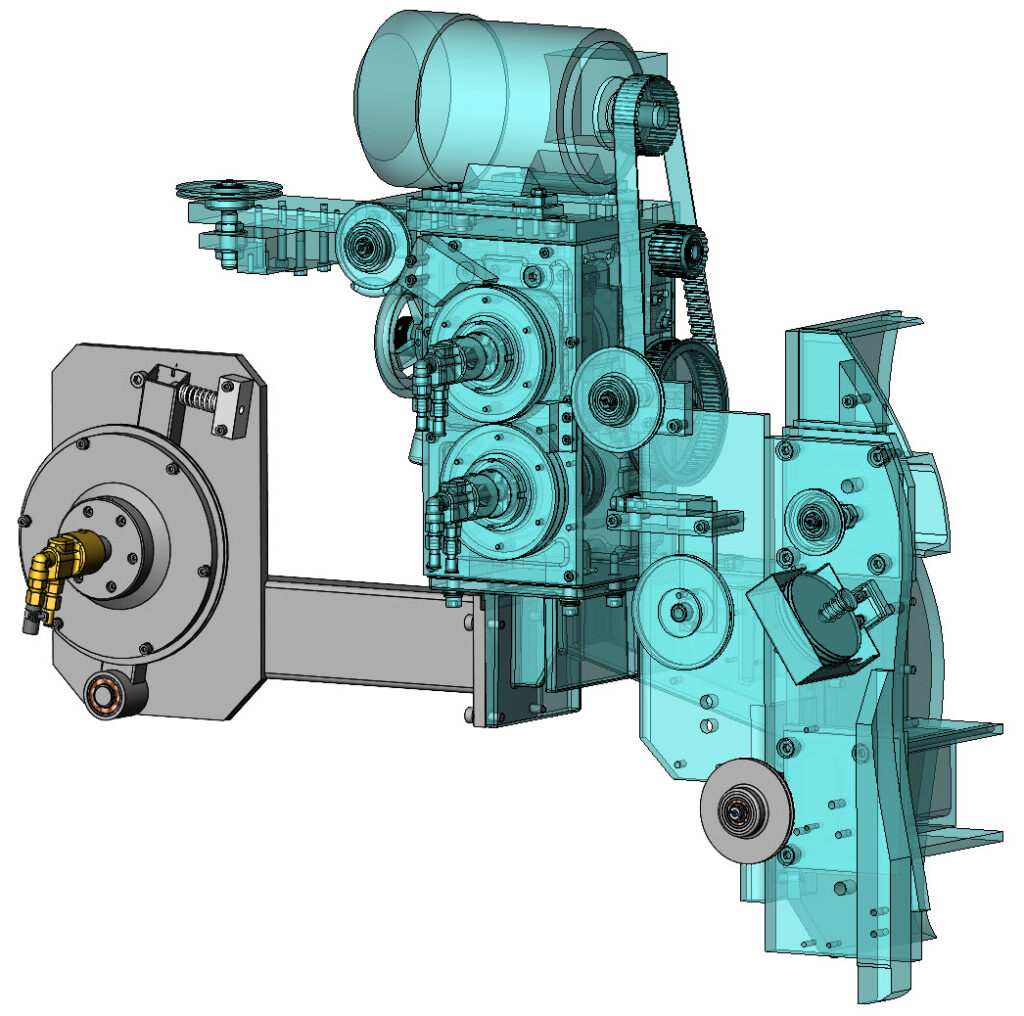

Cooled wire guide roller

Advantages

- Reduced wear

- Much better control of can spacing

- Reliable wire cooling

- Reduction of wire elongation

The new, more effective cooled guide pulley replaces the actual wire tensioning roller and the cooled guide pulley. The new cooled guide pulley combines the functions of both elements. Thanks to a larger cooling surface, not only the copper wire is cooled more effectively, but also the wire stretch is considerably reduced. The new cooled guide pulley is especially effective at high welding frequencies.