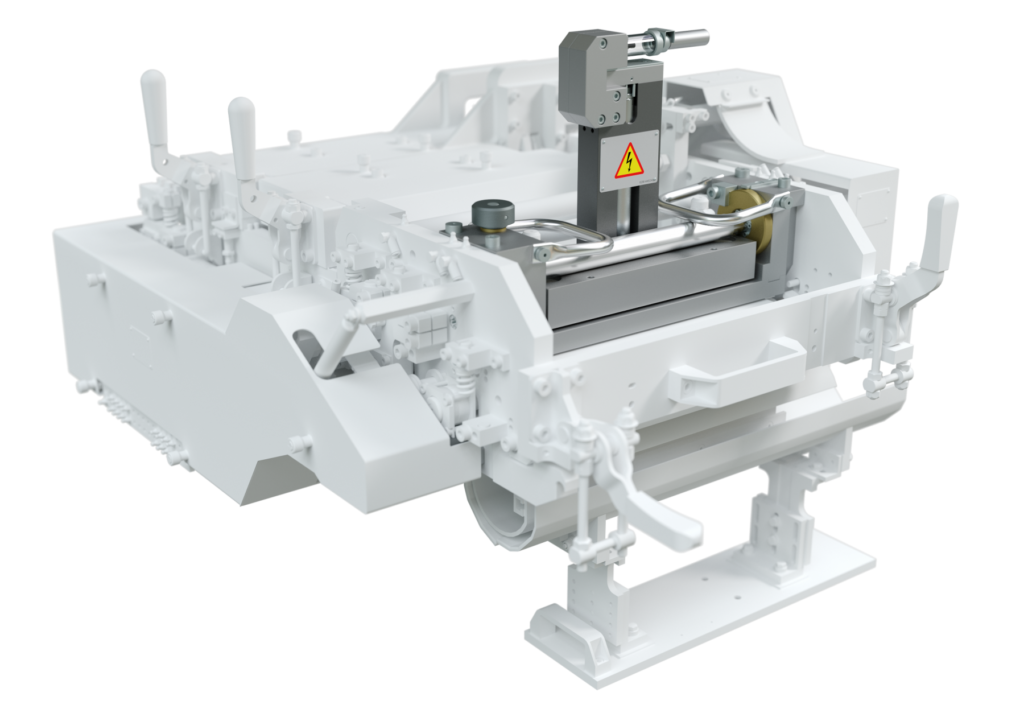

Adaptive rounding system

The inline measuring device is analyzing the body blank material characteristics and is setting automatically the roll form geometry. Therefore, the rounded cylinder has constant geometry independent of material characteristics. The system reaction time is less than 5 ms, therefore, usable up to 900 cpm and can diameter >70 mm.

How does ARS work?

- The processed body blank touches the measuring wedge.

- The measuring wedge detects the contact point of the body blank and transmits the signal to the UNICONTROL

(industrial PC). - The actuator receives a signal from the UNICONTROL to adjust the prerounded or rounded wedge accordingly.

- The body blank in process is rounded.

Options

- SRM Soudronic Rounding Measurement Device

- MFR Motorized Flexer Regulation System with ARS

Advantages

- No adjustments according to yield strength changes within tolerance of tinplate supplier

- Capability of processing continuously different tinplate brands

- Capability of processing continuously a tinplate mix (different qualities, beginning/end of coil)

- Higher line performance due to fewer machine stops

- For can size changeover only the standard procedures are necessary, i.e. no special setup to activate ARS

- Flexibility in sheet material

- Higher productivity and efficiency

- Less scrap